1. Dab tsi yog daim ntawv silicon?

Silicon steel los xij uas siv los ntawm cov kws hluav taws xob feem ntau hu ua silicon steel nplooj ntawv.Nws yog ib hom ferrosilicon mos sib nqus hlau uas muaj cov pa roj carbon tsawg heev.Nws feem ntau muaj 0.5-4.5% silicon thiab dov los ntawm tshav kub thiab txias.Feem ntau, lub thickness yog tsawg dua 1 hli, yog li nws yog hu ua nyias phaj.Qhov sib ntxiv ntawm silicon tsub kom cov hlau hluav taws xob tiv taus thiab siab tshaj plaws sib nqus permeability, txo kev sib txuas, cov tub ntxhais poob (hlau poob) thiab sib nqus aging.

Daim ntawv silicon feem ntau yog siv los ua hlau cores rau ntau yam transformers, motors thiab generators.

Cov ntawv hlau silicon no muaj cov khoom siv hluav taws xob zoo heev, nws yog cov khoom siv hlau nplaum tseem ceeb hauv lub zog, kev sib txuas lus thiab kev lag luam.

2. Cov yam ntxwv ntawm daim ntawv silicon

A. Tsis tshua muaj hlau poob yog qhov tseem ceeb tshaj plaws qhia txog qhov zoo.Txhua lub teb chaws hauv ntiaj teb faib cov hlau poob raws li qib, qhov qis hlau poob, qib siab dua, thiab qhov zoo dua.

B. Siab sib nqus induction.Nyob rau hauv tib lub teb sib nqus, daim ntawv silicon tau txais kev sib nqus siab dua.Lub ntim thiab qhov hnyav ntawm lub cev muaj zog thiab transformer hlau core uas yog tsim los ntawm silicon ntawv yog qhov me me thiab lub teeb, yog li nws tuaj yeem txuag tau tooj liab, insulating cov ntaub ntawv.

C. Siab dua.Nrog du nto, tiaj tus thiab cov tuab tuab, cov ntawv silicon steel tuaj yeem sib sau ua ke siab heev.

D.Qhov saum npoo tau zoo adhesion rau cov zaj duab xis insulating thiab yooj yim rau vuam.

3. Silicon steel sheet manufacturing txheej txheem yuav tsum tau

Khoom thickness: ≤1.0mm;pa 0.35mm 0.5mm 0.65mm;

➢ Khoom siv: ferrosilicon alloy

➢ Cov duab kos duab: kaw lossis tsis kaw;

➢ Qhov yuav tsum tau muaj tseeb: Qib 8 txog 10 raug;

➢ Glitch qhov siab yuav tsum tau: ≤0.03mm;

4. Silicon steel sheet manufacturing txheej txheem

➢ Shearing: Shearing yog ib txoj kev siv lub tshuab txiav los yog txiab.Lub workpiece zoo feem ntau yog yooj yim heev.

➢ Punching: Punching yog hais txog kev siv cov pwm rau kev xuas nrig ntaus, txiav qhov thiab lwm yam txheej txheem zoo ib yam li shearing, tshwj tsis yog tias lub sab sauv thiab sab txiav cov npoo yog hloov los ntawm convex thiab concave pwm.Thiab nws tuaj yeem tsim pwm los punch txhua yam ntawm silicon steel ntawv.

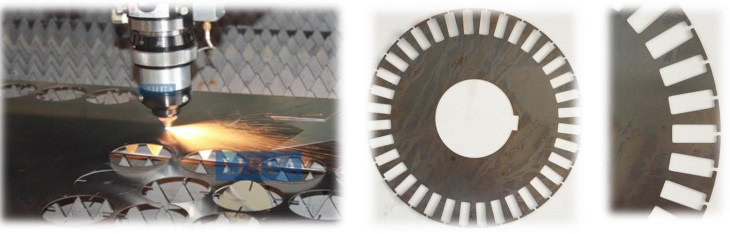

➢ Txiav: Siv lub tshuab txiav laser txiav txhua yam haujlwm.Thiab nws yog maj mam dhau los ua ib txoj kev txiav ntawm kev ua silicon steel ntawv.

➢Crimping: Txij li cov hlau nti burr ncaj qha cuam tshuam rau kev ua haujlwm ntawm lub tshuab hluav taws xob, yog li yog tias qhov burr qhov siab siab tshaj 0.03mm, nws yuav tsum tau crushed ua ntej pleev xim.

➢ Painting: Cov hlau nti saum npoo yuav pleev xim rau cov khoom siv, kub-resistant thiab xeb-pov thawj nyias xim zaj duab xis.

➢ Qhuav: Cov xim ntawm cov ntawv silicon steel yuav tsum tau qhuav ntawm qhov kub thiab txias thiab tom qab ntawd kho rau hauv tawv, muaj zog, siab dielectric zog thiab du nto zaj duab xis.

5. Txheej txheem sib piv - laser txiav

Laser txiav: Cov khoom muab tso rau ntawm lub rooj tshuab, thiab nws yuav txiav raws li qhov kev pab cuam preset lossis duab.Laser txiav yog txheej txheem thermal.

Laser txheej txheem zoo:

➢ Kev ua haujlwm siab tau yooj yim, koj tuaj yeem npaj cov haujlwm ua haujlwm txhua lub sijhawm;

➢ Kev ua haujlwm siab, lub tshuab ua haujlwm zoo tib yam yog 0.01 hli, thiab lub tshuab laser txiav yog 0.02 hli;

➢ Kev cuam tshuam phau ntawv tsawg dua, koj tsuas yog yuav tsum tau teeb tsa cov txheej txheem thiab cov txheej txheem, ces pib ua haujlwm nrog ib lub pob;

➢ Kev ua cov suab nrov tsis zoo;

➢ Cov khoom tiav yog tsis muaj burrs;

➢ Cov txheej txheem ua haujlwm tuaj yeem yooj yim, nyuaj thiab nws muaj qhov chaw ua haujlwm tsis txwv;

➢ Lub tshuab laser txiav tsis tu ncua;

➢ Tus nqi siv tsawg;

➢ Txuag cov ntaub ntawv, koj tuaj yeem siv lub ntug sib koom ua haujlwm los ntawm kev ua zes software kom ua tiav cov haujlwm ua haujlwm zoo, thiab ua kom cov khoom siv ntxiv.

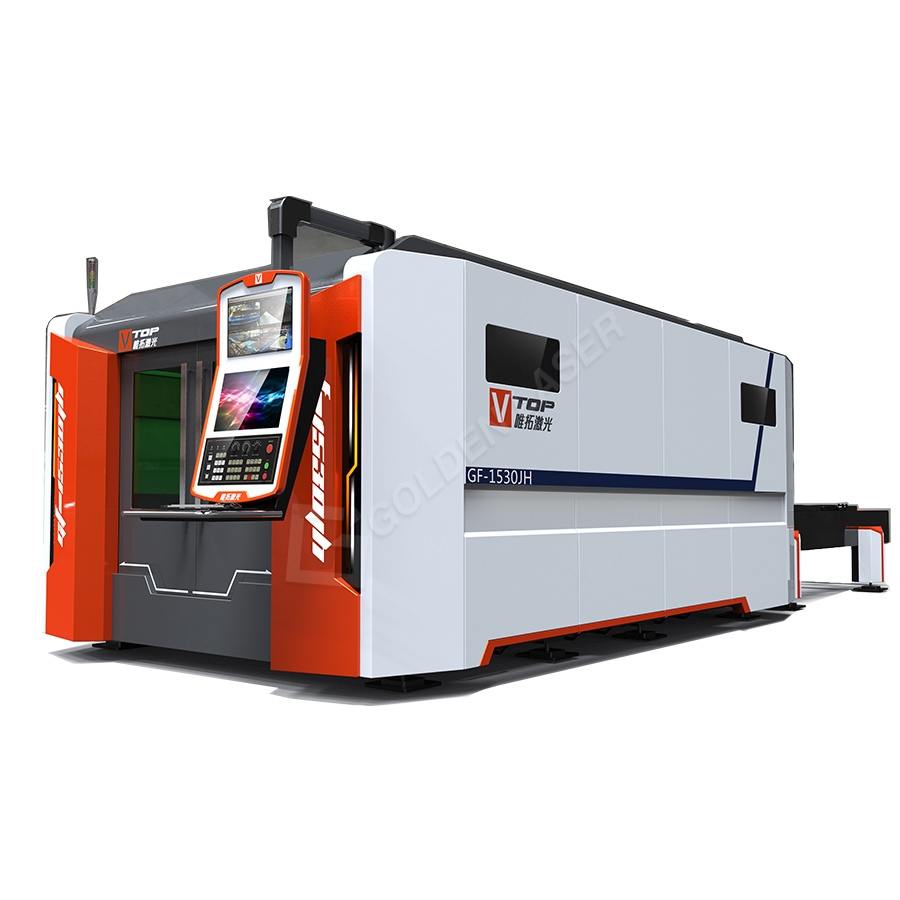

6. Laser tej kev daws teeb meem

Qhib hom 1530 fiber ntau laser cutter GF-1530 siab precision laser cutter GF-6060 Tag nrho enclosed pauv rooj laser cutter GF-1530JH