Qhov mob tam sim no hauv kev lag luam steel rooj tog tsim khoom

1. Cov txheej txheem nyuaj: cov rooj tog zaum ib txwm siv los ntawm cov txheej txheem tsim khoom rau kev xaiv - pom txaj txiav - tig tshuab ua - slanting nto - tho txoj hauj lwm proofing thiab xuas nrig ntaus - laum - tu - hloov vuam yuav tsum muaj 9 txheej txheem.

2. Yooj yim rau kev ua cov raj me me: cov lus qhia tshwj xeeb ntawm cov khoom siv rau kev tsim cov rooj tog tsis paub meej.Qhov tsawg tshaj plaws yog10mm * 10mm * 6000mm, thiab phab ntsa thickness ntawm cov yeeb nkab yog feem ntau0.5-1.5 hli.Qhov teeb meem loj tshaj plaws hauv kev ua cov yeeb nkab me me yog tias cov yeeb nkab nws tus kheej tsis tshua muaj rigidity thiab yooj yim deformed los ntawm sab nraud quab yuam, xws li yeeb nkab dabtsi yog khoov, twisting, thiab bulging tom qab extrusion.Cov txheej txheem ua haujlwm ib txwm muaj, xws li sawing tshuab txiav, sawing tshuab ua ntu thiab beveling, xuas nrig ntaus, drilling tshuab drilling, thiab lwm yam, yog kev sib cuag ua cov txheej txheem uas yuam kom cov duab ntawm cov yeeb nkab yuav deformed los ntawm sab nraud quab yuam extrusion, ntxiv rau ntau yam txheej txheem. thiab ntau tus neeg Kev khiav dej num, kev tiv thaiv lub peev xwm ntawm cov yeeb nkab yog yuav luag tsis muaj, feem ntau mus rau theem kawg ntawm cov khoom tiav, cov yeeb nkab nto tau khawb los yog deformed, thiab nws yuav tsum tau kho cov phau ntawv thib ob, uas yog siv sijhawm ntev. thiab ua haujlwm hnyav.

3. Tsis zoo machining raug: Raws li ib txwm ua txoj kev ntawm steel rooj tog yeeb nkab, tag nrho precision ntawm cov yeeb nkab tsis tuaj yeem lav.Seb nws yog machining xws li sawing tshuab, xuas nrig ntaus tshuab los yog drilling tshuab, muaj machining yuam kev, tshwj xeeb tshaj yog rau cov khoom siv nrog tsawg degree ntawm automation tswj.Qhov ntau cov txheej txheem ua ntu zus, qhov ntau qhov kev ua yuam kev machining accumulates.Tag nrho cov txheej txheem ua tiav saum toj no yuav tsum muaj kev cuam tshuam tib neeg hauv kev tswj cov txheej txheem, thiab tib neeg kev ua yuam kev yuav raug ntxiv rau qhov kawg khoom raug yuam kev.Yog li ntawd, qhov tseeb ntawm cov txheej txheem ntau txheej txheem txheej txheem tsis tuaj yeem tswj tau thiab lav.Nyob rau theem kawg ntawm cov khoom lag luam, phau ntawv kho thiab kho yog lub xeev ib txwm muaj.

4. Kev ua haujlwm tsawg: Lub tshuab sawing muaj qee qhov zoo rau kev sib dhos thiab sib dhos ntawm ntau cov kav dej, tab sis qhov kev ua haujlwm ntawm cov yeeb nkab qhib yog qhov tsawg heev, thiab nws yog ib qho tsim nyog los hloov lub kaum sab xis thiab txoj hauj lwm ntawm cov saw hniav. rau ntau qhov chaw thiab txiav, uas tsis muaj txiaj ntsig lossis ua tiav.Tswj qhov tseeb.Punch presses yuav siv tau rau batch xuas nrig ntaus ntawm cov qauv zoo li lub qhov puag ncig thiab square qhov.Txawm li cas los xij, muaj ntau hom hom qhov hauv kev lag luam rooj tog.Lub tshuab xuas nrig ntaus muaj ntau lub peev xwm ua rau cov qhov zoo li no, tshwj tsis yog cov neeg siv khoom siv ntau qhov kev paub thiab tus nqi los tsim ntau yam pwm sib txawv.Txhua leej txhua tus paub tias lub tshuab drilling tsuas tuaj yeem ua qhov puag ncig, thiab kev ua haujlwm tsuas yog txwv.Cov kev txwv kev ua haujlwm thiab kev ua tsis tau zoo ntawm txhua qhov txheej txheem ua rau tsis muaj txiaj ntsig hauv tag nrho cov khoom tsim tawm.

5. Cov nqi zog siab: Rau cov sawing, xuas nrig ntaus thiab drilling hauv cov txheej txheem ua haujlwm ib txwm muaj, qhov loj tshaj plaws yog kev cuam tshuam rau tib neeg.Kev ua haujlwm ntawm txhua lub cuab yeej yuav tsum tau tswj xyuas manually, vim tias qhov kev ua haujlwm ntawm cov khoom siv no muaj tsawg heev.Rau kev ua haujlwm ntawm cov khoom siv tsis yog-daim ntawv ntawm cov kav dej, kev tswj xyuas phau ntawv yuav tsum tau ua rau txhua qhov ntawm kev pub mis, kev tso chaw, ua haujlwm thiab rov ua dua.Yog li ntawd, feem ntau nws tuaj yeem pom nyob rau hauv rooj tog kev lag luam kev cob qhia, ntau yam khoom siv, ntau tus neeg ua haujlwm.Niaj hnub no, nrog kev txhim kho ntawm kev ua lag luam, cov tswv lag luam tau yws yws tias cov neeg ua haujlwm tau dhau los ua ntau lub xov tooj ntawm tes, thiab lawv tau dhau los ua nyuaj rau nrhiav neeg ua haujlwm.Cov nyiaj ua haujlwm ntawm cov neeg ua haujlwm yuav tsum tau nce.Cov nqi ua haujlwm yuav suav rau feem ntau ntawm cov txiaj ntsig ntawm tuam txhab.

6. Cov khoom tsis zoo: qhov raug thiab zoo ntawm cov yeeb nkab tiav ncaj qha cuam tshuam rau cov khoom kawg.Burr, peripheral deformation ntawm lub tshuab, av nyob rau hauv lub puab phab ntsa ntawm cov yeeb nkab, thiab lwm yam yog tsis tso cai rau high-end rooj tog tsim.Txawm li cas los xij, txawm tias nws yog sawing tshuab txiav, xuas nrig ntaus, los yog drilling, nws yog undoubtedly tias cov teeb meem no yuav tshwm sim tom qab ua cov yeeb nkab.Los ntawm txhais tes deburring, trimming, thiab tu ua hauj lwm nyob rau hauv lub tom ntej ua hauj lwm yuav zam tsis tau.

7. Muaj qhov tsis muaj qhov hloov pauv loj: Tam sim no, qhov kev thov rau cov neeg siv khoom tau dhau los ua tus kheej, yog li kev tsim cov rooj tog zaum tom ntej yog qhov tseeb ntau thiab ntau tus kheej.Cov tsoos sawing tshuab, xuas nrig ntaus tshuab, drilling tshuab thiab lwm yam khoom siv yog cov laus-fashioned, thiab cov khoom siv tes ua yooj yim tsis tuaj yeem txhawb nqa tus qauv tshiab thiab muaj tswv yim kev tshoov siab.Ci rau hauv kev muaj tiag.Qhov kev ua tsis tau zoo, qhov tsis zoo, thiab tus nqi siab tsis txaus ntawm cov kev ua haujlwm ib txwm ua yuav cuam tshuam qhov kev tshawb fawb thiab kev tsim cov khoom tshiab, thiab muab lub lag luam pib lub taub hau.

Dab tsi tshiab tuaj yeem ua tiav qhov tsis siv neeg laser yeeb nkab cutter coj mus rau rooj tog

kev lag luam?Cov yam ntxwv ntawm cov khoom siv yog dab tsi?

1. Lub zog tshiab tseem ceeb hauv kev ua cov kav hlau bismuth: fiber ntau laser txiav yog riam phom tshiab rau kev ua hlau hauv xyoo tas los.Tom qab ntawd, nws yog maj mam hloov cov tsoos shearing, xuas nrig ntaus, drilling thiab sawing.Cov khoom siv yeeb nkab kuj yog hlau, thiab cov rooj tog kev lag luam yeeb nkab yog ua los ntawm stainless hlau, uas yog nyob rau hauv txoj kab nrog qhov zoo ntawm fiber ntau laser txiav.Fiber laser high-efficiency photoelectric conversion efficiency, zoo beam zoo, siab focusing ceev laser zog, nplua txiav qhov sib txawv, yuav siv tau nyob rau hauv lub rooj tog kev lag luam yeeb nkab ua.Lub rotary chuck ntawm Vexo laser tag nrho tsis siv neeg fiber ntau laser txiav tshuab muaj kev sib hloov ceev txog li 120 rpm, thiab lub peev xwm ntawm fiber ntau laser txiav cov hlau stainless ntawm ultra-siab ceev.Kev sib xyaw ua ke ntawm ob ua rau cov yeeb nkab ua kom zoo ib nrab ntawm kev siv zog.Nyob rau tib lub sijhawm, thaum lub fiber ntau laser txiav cov yeeb nkab, lub laser txiav lub taub hau tsis hu rau cov yeeb nkab, tab sis yog laser-projected mus rau saum npoo ntawm cov yeeb nkab rau melting thiab txiav, yog li nws belongs rau hom tsis sib cuag, kom tsis txhob muaj qhov teeb meem ntawm cov yeeb nkab deformation nyob rau hauv cov tsoos ua hom.Cov seem txiav los ntawm fiber ntau laser yog zoo huv si thiab du, thiab tsis muaj burr tom qab txiav.Yog li ntawd, qhov zoo dua ntawm kev ua haujlwm thiab kev ua haujlwm zoo yog qhov tseem ceeb lav rau fiber ntau laser txiav los ua lub zog tshiab hauv cov yeeb nkab hlau ua.

2. Customized configuration los pab kev ua hauj lwm efficiency thiab zoo upgrade: rau cov rooj tog kev lag luam, me me, nyias, cov khoom yog cov yam ntxwv ntawm stainless hlau, peb siv tsom configuration los txhim kho kev ua hauj lwm efficiency thiab ua zoo ntawm cov rooj tog kev lag luam yeeb nkab.Tshwj xeeb module fiber ntau laser, tshwj xeeb fiber ntau, uas tsis yog-pas focal ntev fiber ntau laser txiav lub taub hau, tag nrho cov zoo ntawm cov configuration tsom rau kev txiav peev xwm ntawm cov yeeb nkab tshwj xeeb hauv kev lag luam rooj tog, kev ua tau zoo ntawm cov yeeb nkab stainless hlau ntawm tib lub ntsiab lus yog txiav los ntawm peb cov txheej txheem fiber ntau laser txiav tshuab Ze li 30%, thaum nqa cov txiaj ntsig zoo dua.

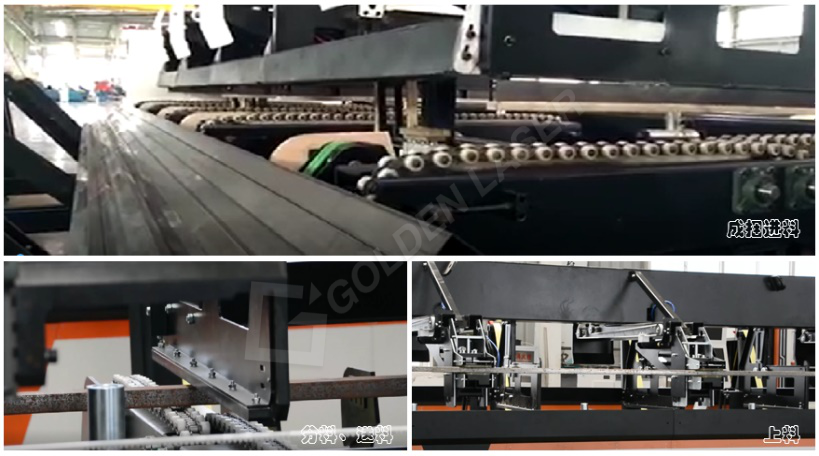

3. Batch tsis siv neeg cov kav dej: Tom qab cov kav dej bundled tau muab tso rau hauv lub tshuab pub mis tsis siv neeg, ib lub pob pib, thiab cov kav dej tau txais kev pub, faib, pub, txiav clamped, pub, txiav thiab unloaded hauv ib mus.Ua tsaug rau peb tsis siv neeg thauj khoom thiab tshem tawm kev ua haujlwm tau tsim los ntawm lub siab tsis siv neeg laser yeeb nkab txiav tshuab, cov yeeb nkab tuaj yeem paub txog qhov ua tau ntawm batch.Cov khoom siv yeeb nkab me me hauv kev lag luam rooj tog siv qhov chaw tsawg dua.Cov khoom siv tib yam tuaj yeem ntim ntau cov kav dej hauv ib qho kev thauj khoom, yog li nws muaj qhov zoo dua.Ib tug neeg yog nyob rau hauv lub luag hauj lwm, thiab tag nrho cov txheej txheem yuav ua tiav nws.Qhov no yog lub embodiment ntawm efficiency.

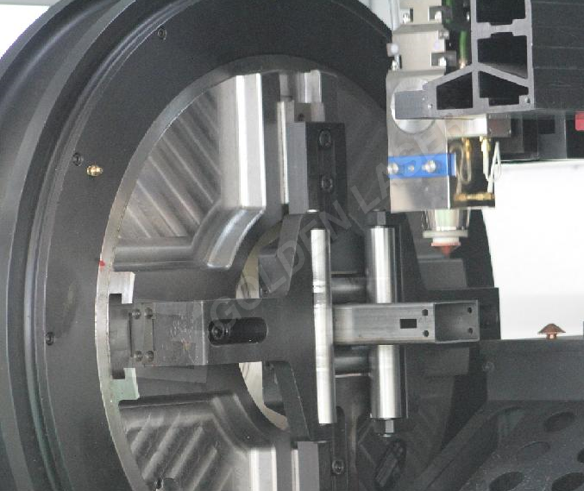

4. Tube clamping so: Rau lub raj me me ntawm kev lag luam rooj tog, laser txiav chuck yog nruj dua.Yog hais tias lub clamping quab yuam loj heev, cov yeeb nkab tau yooj yim deformed, lub clamping quab yuam me dhau, thiab cov yeeb nkab ntev ntev.Thaum lub sij hawm txiav, cov yeeb nkab tig ntawm kev kub ceev thiab yooj yim detached.Yog li ntawd, lub clamping quab yuam ntawm chuck ntawm cov yeeb nkab txiav cov cuab yeej hauv kev lag luam rooj tog yuav tsum tau kho, thiab txoj kev debugging yuav tsum tau yooj yim paub.Lub self-centering pneumatic chuck configured los ntawm tag nrho cov tsis siv neeg laser yeeb nkab tej tshuab yuav paub nws tus kheej nyob rau hauv cov yeeb nkab clamping, ib zaug nyob rau hauv lub clamping txoj hauj lwm, thiab cov yeeb nkab chaw yog nyob rau hauv ib zaug.Nyob rau tib lub sijhawm, lub zog ntawm chuck clamping yog muab los ntawm cov cua nkag.Cov kab hluav taws xob nkag tau nruab nrog lub tshuab hluav taws xob siab tswj lub valve, thiab lub zog clamping tuaj yeem hloov kho tau yooj yim los ntawm kev tig lub pob qhov rooj ntawm lub tshuab cua siab tswj valve.

5. Kev ua tau zoo thiab txhim khu kev qha kev txhawb nqa muaj peev xwm: qhov ntev ntawm cov yeeb nkab ntev, qhov loj dua qhov deformation ntawm cov yeeb nkab tom qab nws raug tshem tawm.Tom qab cov yeeb nkab tau thauj khoom, txawm hais tias lub chuck yog clamped ua ntej thiab tom qab, qhov nruab nrab ntawm cov yeeb nkab yuav sag vim lub ntiajteb txawj nqus, thiab kev sib hloov ceev ntawm cov yeeb nkab yuav dhau los ua tus cwj pwm hla, yog li kev txiav yuav cuam tshuam rau kev txiav precision. ntawm lub cev.Yog tias txoj kev hloov kho cov lus qhia ntawm cov khoom siv saum toj kawg nkaus tau txais yuav, tsuas yog kev txhawb nqa ntawm cov yeeb nkab puag ncig thiab cov yeeb nkab square tuaj yeem daws tau, tab sis rau cov yeeb nkab txiav ntawm cov ntu tsis sib xws xws li cov yeeb nkab thiab cov yeeb nkab elliptical, phau ntawv hloov kho ntawm cov khoom siv sab saum toj yog siv tsis tau..Yog li ntawd, kev txhawb nqa saum toj kawg nkaus thiab tus Tsov tus tw ntawm peb cov cuab yeej teeb tsa yog kev daws teeb meem.Thaum cov yeeb nkab tig, nws yuav qhia cov postures sib txawv hauv qhov chaw.Kev txhawb nqa cov khoom siv saum toj kawg nkaus thiab cov khoom siv tus Tsov tus tw tuaj yeem hloov kho qhov siab ntawm lub sijhawm tiag tiag raws li kev hloov pauv ntawm cov yeeb nkab tus cwj pwm, yog li nws tuaj yeem ua kom ntseeg tau tias hauv qab ntawm cov yeeb nkab yog ib txwm sib cais los ntawm sab saum toj ntawm cov khoom txhawb nqa, uas. plays lub zog txhawb nqa ntawm cov yeeb nkab.nyhuv.Kev txhawb nqa cov khoom siv saum toj kawg nkaus thiab cov khoom siv ntab ntab ntab ua haujlwm ua ke los tswj qhov chaw ruaj khov ntawm cov yeeb nkab ua ntej thiab tom qab txiav, yog li ua kom cov txiav precision.

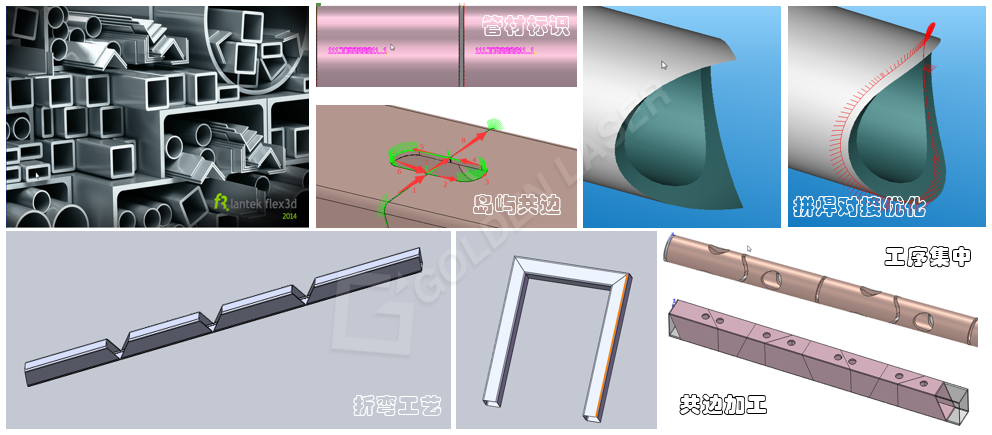

6. Cov txheej txheem concentration thiab txheej txheem muaj ntau haiv neeg: siv 3D kos duab software los tsim ntau yam qauv uas yuav tsum tau ua, xws li txiav tawm, beveling, qhib, notching, marking, thiab lwm yam, thiab ces hloov mus rau hauv NC machining cov kev pab cuam nyob rau hauv ib kauj ruam los ntawm kev ua haujlwm zes software., tawm tswv yim rau kev CNC system ntawm cov cuab yeej teeb tsa, thiab tom qab ntawd muab cov txheej txheem txiav cov txheej txheem tsis sib xws los ntawm cov txheej txheem database, thiab kev ua haujlwm tuaj yeem pib nrog ib lub pob.Cov txheej txheem txiav automated ua tiav cov tsoos sawing, tsheb, xuas nrig ntaus, drilling thiab lwm yam txheej txheem.Lub hauv paus ua tiav ntawm cov txheej txheem coj tuaj yeem tswj tau thiab lav kev ua haujlwm raug, nrog rau kev ua haujlwm siab thiab tus nqi qis.Qhov sib ntxiv thiab rho tawm ntawm cov teeb meem lej lej no yuav tsum meej meej rau txhua tus neeg ua lag luam.

7. Kev siv cov fiber ntau laser txiav tshuab rau steel rooj tog kev lag luam kav tau coj cov kev hloov tshiab rau cov yeeb nkab ua tshuab.Txij li thaum peb tau pib tshawb fawb thiab kev loj hlob ntawm tag nrho cov tsis siv neeg fiber ntau laser txiav tshuab, peb tau positioned peb tus kheej nyob rau hauv kev lag luam, ua rau kev lag luam nyob rau hauv-tob, kev, thiab ceev faj.Kev lag luam steel rooj tog tau dhau los ua qauv qauv rau peb cov yeeb nkab txiav tshuab.Ntawm txoj kev ntawm R & D, kev tshawb nrhiav thiab kev tsim kho tshiab ntau xyoo, peb tau sau ntau yam kev paub dhau los thiab tsim ntau yam kev ua tau zoo thiab kev tsim kho tshiab rau cov rooj tog tsim kev lag luam.Txheej txheem.Tus thawj yuav tsum tau welded, tam sim no yuav buckled thiab tsau;tus thawj yuav tsum tau spliced, yuav ncaj qha khoov;qhov kev siv cov yeeb nkab qub yog tsawg heev, tam sim no tuaj yeem siv cov ntug txiav ua haujlwm kom ua tiav cov yeeb nkab zoo dua thiab ntau cov khoom tawm, thiab lwm yam, cov txheej txheem tshiab no tau siv rau hauv cov rooj tog kev lag luam yeeb nkab ua cov ntaub ntawv, thiab cov txiaj ntsig tau zoo. cov neeg siv ntawm peb cov khoom siv.

Laser txiav tshuab rau hlau rooj tog