Ku soo dhawoow Laser Golden

Soo hel Cutter-ka Tuubada Laser-ka ugu Haboon

i Taxanaha

Taxanaha Intelligent "i" waa garaad, dhijitaal ah iyo mashiinka goynta tuubbada laysarka oo dhan-dhamaadka sare leh.

2D iyo 3D Laser Goynta Madaxa | Raadiyaha tuubada horumarsan ee otomaatiga ah | Nidaamka MES waafaqi

Taxanaha Mega

Taxanaha MEGA waa 3 iyo 4 chucks mashiinka goynta tube laser

loo sameeyay tuubooyinka ultra-weyn, culus, iyo dheer iyo jarista profiles.

qaabeynta dabacsan | Qaab dhismeedka dhinaca ka laadlaadda | "0" Doorashada Dawaarlayaasha

Taxanaha S

Smart "S" taxane ultra-yar mashiinka goynta laser

Gaar ahaan loogu talagalay tuubooyinka yaryar.

nidaamka xakamaynta garaadka, qaabaynta tuubada yar ee isku xidhka, quudinta si otomaatig ah u dhamaystiran, goynta, iyo dib u celinta si loo gaadho xawaaraha sare iyo saxsanaanta sare ee tuubooyinka yaryar.

Raadiyaha tuubada naqshadaynta is haysta | Heerka sare ee otomaatiga | xawaaraha sare iyo saxnaanta weyn

L Taxanaha

Qaab-ku-dhejinta Model Mashiinka goynta laser-ka yar

Hagaajinta waxtarka wax soo saarka oo dhan.

Isku-xidhka tuubo yar oo leh quudin, goyn, iyo ururin si toos ah u toosan. Tani waxay si degdeg ah oo sax ah u goysaa tuubooyinka yaryar.

Raadiyaha tuubada naqshadaynta is haysta | Heerka sare ee otomaatiga | xawaaraha sare

F Taxanaha

EcoFlex "F" waa mashiinka goynta tuubooyinka laysarka ee dhaqaale.

Waara oo si ballaaran loo dabaqi karo

Fudud in lagu shaqeeyo | Baaxadda habaynta | Raadiyaha tuubbada otomaatiga ah iyo semi-otomaatigga ah

Taxanaha HP

H Beam mashiinka goynta laser

Gaar ahaan loogu talagalay beam H, waxaan goynta alwaax, oo si ballaaran loo isticmaalo dhismaha iyo warshadaha buundada.

Qaab dhismeedka Buundada | Madaxa Laser 3D | Habbee Dhererka

FAAHFAAHIN DHEERAAD AH KA CODSADAY XIGASHO

Dhammaan waxaad u baahan tahay inaad ka ogaato Mashiinka Goynta Tube Laser 2025

Mashiinka goynta tuubbada laysarka waa hal nooc oo ka mid ah mishiinka goynta laser fiber-ka kaas oo gooya kaliya tuubooyinka walxaha birta ah ee kala duwan (birta aan daahin, birta kaarboonka, naxaasta, Profile Aluminium),ka duwanqalabka kale ee tuubooyinka goynta, waa ataabasho la'aanhabka goynta saxda ah sare, waama dhalanroginta lagu guda jiro wax soo saarka.Fudud in la gooyonaqshado adagon tuubada iyo daloolin saxnaanta sare ee tuubada laysarka gooya.Si fudud loobeddel naqshadaada wax soo saarkahabka ku jira kontoroolka laser CNC ee caqliga leh.La habeeyayChuck Meet Tube Kala duwan iyo Dhexroor Profile iyo Miisaanka si loo hubiyo Natiijada Goynta Laser Weyn

waa maxayFaa'iidada Mashiinnada Goynta Tube Laser?

1. Ku haboon Tubooyin Qaabaysan oo Badan

Wareeg, labajibaaran, leydi, iyo tuubooyinka kale ee gaarka ah ee Qaabaysan, Channel Steel, I Beam, Profile, iyo wixii la mid ah.

2. Waxtarka waxtarka sare leh

Saxnaanta sare ee ku saabsan 0.1m, fududahay in la gooyo naqshad kasta oo adag gaar ahaan daloolinta shaqada tuubada goynta.

3. Cadaadis la'aan dusha birta

Goynta laser waa habka goynta aan taabasho lahayn ee heerkulka sare, ma cadaadin doono alaabta, mana jiraan wax qalloocan ee wax soo saarka.

4. Aqoonsiga Dhuumaha Alxanka

Aqoonso oo iska ilaali xadhkaha alxanka si aad u yarayso jabinta inta lagu jiro jarida laysarka.

Mashiinka Goynta Tube Laser

Qaybaha ugu muhiimsan

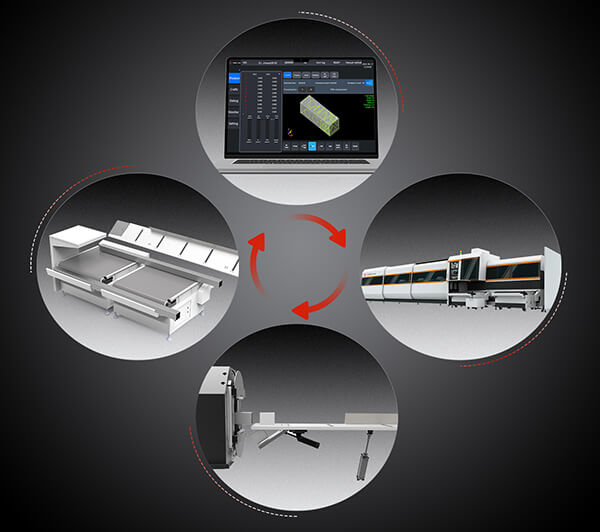

Sidee U Shaqeeyaa Mashiinka Goynta Tuubada Laser-ka?

Farsamaynta mashiinka goynta tuubada laysarka ayaa ugu horayn sidan oo kale ah.

1.Geli nooca tuubbada gelinta tuubada laysarka ee Nesting (Lanteck),

Deji qiyaasta naqshadaynta saxda ah ee goynta iyadoo loo eegayo dhumucda birta iyo nooca birta, birta khafiifka ah, birta aan fiicnayn, Al, Brass, iyo wixii la mid ah.

2.U dhoofi faylka galka mashiinka goynta tuubada laysarka,

Dhammaan qaabka caadiga ah ee tuubooyinka birta ayaa ku tusi doona qaabka 3D ee shaashadda hawlgalka, waxaad si cad u hubin kartaa naqshadeynta.

3.Ku rarida tuubada saxda ah mashiinka goynta tuubada laysarka

Nidaamka rarka otomaatiga ah, uma baahnid inaad ka walwasho tuubada khaldan ee isku dhafan ee isku dhafan ee tuubooyinka, waxay si toos ah u cabbiri doontaa ama qaylo-dhaan haddii aadan dejin shaqada goynta isku dhafka ah ee barnaamijka goynta.

4.Bilow inaad gooyso oo ururiso tuubada birta ah ee dhammaatay.

Hubi in qaboojiyaha biyaha iyo kombaresarada hawadu ay furan yihiin ka hor inta aanad riixin badhanka "bilow", dawaarlaha tuubada ayaa raaci doona ilaa sanduuqa qashin ururinta ee hoos yimaada mashiinka, qaybaha dhammeeyeyna waxay u diri doonaan miiska gudbinta ee sanduuqa isku dhafka.

Maxaad u doorataa Mashiinka Goynta Tuubada Laser-ka ee Birta?

Tixgelinta Marka aad iibsanayso Mashiinka Goynta Tuubbada Laser

1. Waa maxay dhumucda ugu weyn ee aad u baahan tahay inaad gooyso?

Waxaa muhiim ah in la doorto mashiinka goynta laser birta ah ee saxda ah sababtoo ah awoodda laser ee kala duwan qiimihiisu aad ayuu u kala duwanaan doonaa.

Dooro iyadoo loo eegayo dhumucda ugu badan, maalgelintu waxay si fudud uga gudbi doontaa miisaaniyadaada.

2. Ma u baahan tahay Qaabka Tuubooyinka Birta?

Tuubada birta qaabka caadiga ah, way fududahay in la gooyo, sida wareegsan, labajibbaaran, iyo leydi.

Haddii loo baahdo in la gooyo tuubooyinka qaabaysan, sida Channel Steel, I beam, tuubooyinka nooca C ayaa ka fiican in aad ka hubiso khabiir si aad u hubiso in la gooyo.

3. Ma u baahan tahay inaad ku xidhid nidaamka ERP mise maya?

Tixgeli xaaladdaada warshadda iyo xulashada xakamaynta laysarka ee ku habboon waxay noqon doontaa doorasho wanaagsan.

Haddii aysan jirin baahi ku xirta nidaamyada ERP mashiinnada wax-shiidka kale, kantaroolaha Shiinaha FSCUT wuxuu noqon doonaa doorasho wanaagsan, interface saaxiibtinimo iyo fududahay in lagu shaqeeyo.

4. Fahamka Dalabka Codsiga Warshadaha

Mashiinka goynta laysarka ee waxtarka leh ayaa loo qaabeeyey iyadoo loo eegayo baahida macaamiisha oo faahfaahsan. Shaqooyin badan ayaa la habeeyey ka dib markii si qoto dheer loo darso baahiyaha wax soo saarka macmiilka.

Tani waxay buuxinaysaa baahida suurtagalka ah waxayna fududaynaysaa oo kordhisaa waxtarka khadka wax soo saarka.

Awoodda R&D ee xooggan waa muhiim marka aad hesho soosaarayaasha mashiinka goynta tuubbada laser-ka.

5. Tayada mashiinka iyo waayo-aragnimada warshadda

Si aad u bixiso mashiinka goynta laser tube bir tayo wanaagsan, mid u baahan yahay waayo-aragnimo wanaagsan ee dariiqa iftiinka, wadada korontada, jidka biyaha, iyo 3D technology goynta laser. Ma aha oo kaliya inay wada curiyaan.

Laser-ka dahabiga ah wuxuu leeyahay waayo-aragnimo 20 sano ah oo soo saarista tayada wanaagsan iyo mashiinnada goynta tuubbada fiber-ka, waayo-aragnimo qani ah oo leh mashiinnada goynta laser-ka ee birta ah, kooxda adeegga ka dib si loo hubiyo khibradda isticmaale ee wanaagsan ee mashiinka goynta tuubada laser-ka.

6. Adeegga Iibka Kadib

Laser Golden dhoofiyaa mishiinka goynta laser in ka badan 120 dalalka iyo magaalooyinka kala duwan.

Waxaad hubin kartaa tayada mashiinkayaga gudaha oo waxaad ku raaxaysan kartaa guri-ilaa-albaab wakhtiga adeegga ka dib adoo si toos ah u sii maraya wakiilkayaga ama warshadda. Waxaan sidoo kale leenahay aXarunta Adeegga EuroNederlaan

Waxaan jeclaan lahayn inaan kula shaqeyno

Fadlan noo soo dir fariin haddii aad wax su'aalo ah ama codsiyo ah oo ku saabsan mishiinnada goynta laysarka ee birta ah.