Raadi Mashiinka Jarida Tube Laser-ka ugu Habboon

CODSO QIIMEYN SI AAD U HESHO FAAHFAAHIN DHEERAAD AH

Dhammaan Waxaad U Baahan Tahay Inaad Ka Ogaato Mashiinka Jarida Tuubada Laser-ka ee 2024

Mashiinka jarista tuubada laysarka waa nooc ka mid ah mashiinka jarista laysarka fiber-ka kaas oo kaliya jara tuubooyinka iyo tuubooyinka birta kala duwan (birta aan daxalka lahayn, birta kaarboon, naxaasta, Aluminium Profile),ka duwanqalabka kale ee jarista tuubooyinka, waaaan taabasho lahaynhabka goynta saxda ah ee sare, waaqallooc la'aaninta lagu jiro wax soo saarka.

Si fudud loo jari karonaqshado adagtuubada iyo dalool sax ah oo uu sameeyay gooye tuubo laysar ah.

Way fududahay in la sameeyobeddel naqshaddaada wax soo saarkahabka xakamaynta laysarka CNC ee caqliga badan.

La habeeyeyChuck La kulan Tube iyo Profile Ballaca iyo Miisaanka kala duwan si loo hubiyo Natiijada Jarida Laser weyn

Waa maxayFaa'iidada Mashiinnada Jarida Tuubada Laser-ka?

1. Ku habboon tuubooyin badan oo qaabaysan

Dhumuc, Labajibbaaran, Laydi, iyo tuubooyin kale oo gaar ah oo qaabaysan, Birta Kanaalka, Birta I, Muuqaal, iwm.

2. Dalool Waxtar Sare leh

Saxnaan sare oo qiyaastii ah 0.1m, si fudud loo jari karo naqshad kasta oo adag gaar ahaan daloolinta shaqada jarista tuubooyinka.

3. Cadaadis la'aan dusha sare ee birta ah

Jarista laysarka waa hab goyn heerkul sare leh oo aan taabasho lahayn, ma cadaadin doonto agabka, mana jirto wax qallooc ah oo ku jira wax soo saarka.

4. Tuubada Alxanka Aqoonso

Aqoonso oo iska ilaali khadadka alxanka si loo yareeyo jabka inta lagu jiro jarista laysarka.

Qaybaha ugu muhiimsan ee Mashiinka Jarida Tube-ga Laser-ka

Sidee loo shaqeeyaa Mashiinnada Jarida Tube-ga Laser-ka?

Habka mashiinka goynta tuubada laysarka ayaa ugu horreyn sidan u eg.

1. Ku rid tuubada qaabka saxda ah barnaamijka tuubada laysarka Nesting (Lanteck),

Deji halbeegga saxda ah ee naqshadeynta jarista iyadoo loo eegayo dhumucda birta iyo nooca birta, birta khafiifka ah, birta aan miridhku lahayn, Al, Naxaasta, iwm.

2. Faylka u dhoofi kontoroolka mashiinka jarista tuubada laysarka,

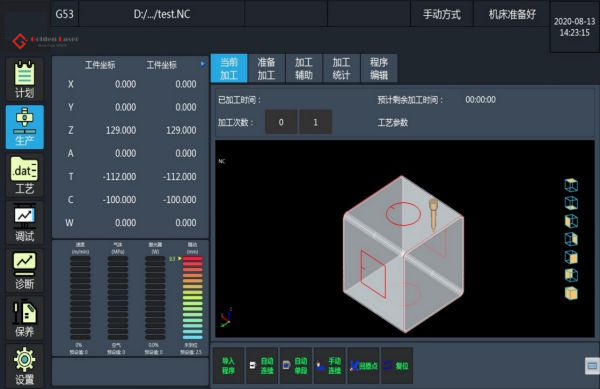

Dhammaan qaabka caadiga ah ee tuubooyinka birta ah waxay ku tusi doonaan qaabka 3D shaashadda hawlgalka, waxaad si cad u hubin kartaa naqshadda laba jeer.

3. Ku rarista tuubada saxda ah mashiinka jarista tuubada laysarka (Rarista gacanta ama si toos ah iyadoo la dooranayo),

Iyada oo la adeegsanayo nidaam rarista otomaatiga ah, uma baahnid inaad ka walwasho tuubada khaldan ee lagu qasay xirmo tuubooyin ah, si toos ah ayay u cabbiri doontaa ama u qaylin doontaa haddii aadan shaqada jarista isku-dhafka ah ku dejin barnaamijka jarista.

4. Bilow mashiinka jarista tuubada laysarka oo soo ururi tuubada birta ah ee la dhammeeyay.

Hubi in qaboojiyaha biyaha iyo kombaresarada hawada ay furan yihiin ka hor intaadan riixin badhanka "bilow", qaybta dambe ee tuubada ayaa hoos ugu sii socon doonta sanduuqa ururinta qashinka ee hoos yimaada salka mashiinka, qaybaha la dhammeeyayna waxay u diri doonaan miiska rarista si loogu sameeyo sanduuqa isku-xidhka.

Maxaad u Doorataa Mashiinka Jarida Tube-ga Birta ah ee Laser-ka?

Tixgelin Marka Iibsashada Mashiinka Jarida Tube Laser

#1 Waa maxay dhumucda ugu weyn ee aad u baahan tahay inaad jarto?

Waa muhiim inaad doorato mashiinka jarista laser-ka birta ee awoodda laysarka saxda ah sababtoo ah awoodda laysarka ee kala duwan qiimuhu aad buu u kala duwanaan doonaa.

Dooro sida ugu badan ee dhumucdiisu tahay, maalgashigu si fudud ayuu uga gudbi doonaa miisaaniyaddaada.

#3 Ma u baahan tahay inaad ku xirto Nidaamka ERP mise maya?

Ka fiirso xaaladdaada warshadeed, doorashada kontoroolka laysarka ee ku habboon waxay noqon doontaa doorasho wanaagsan.

Haddii aan loo baahnayn in nidaamyada ERP ay ku xidhmaan mashiinnada kale ee wax lagu shiido, kontoroolka Shiinaha ee FSCUT wuxuu noqon doonaa doorasho wanaagsan, is-dhexgal saaxiibtinimo leh iyo mid fudud in la shaqeeyo.

#4 Fahmidda Baahida Codsiga Warshadaha

Mashiinka goynta laser-ka ee waxtarka leh waxaa loogu talagalay iyadoo loo eegayo baahida macaamiisha ee faahfaahsan, shaqooyin badan ayaa loo habeeyey ka dib markii si qoto dheer loogu barto wax soo saarka macaamiisha.

Taas oo daboolaysa baahida suurtagalka ah isla markaana fududaynaysa oo kordhinaysa hufnaanta khadka wax soo saarka.

Awood xooggan oo cilmi-baaris iyo horumarin ah ayaa muhiim ah marka aad hesho soo-saareyaasha mashiinka jarista tuubada birta ah ee laser-ka.

#2 Ma u baahan tahay qaabaynta Tuubooyinka Birta ah?

Tuubo bir ah oo qaab caadi ah leh, way fududahay in la jaro, sida wareegsan, afargeesle, iyo afargeesle.

Haddii loo baahdo in la jaro tuubooyinka qaabaysan, sida Channel Steel, I beam, iyo tuubooyinka nooca C, waxaa fiican inaad la tashato khabiir si aad u hubiso in la jaro.

#5 Khibrad Tayada Mashiinka iyo Warshadda

Maadaama qiimaha isha laysarka uu aad u yaraaday, waxaa jira warshado badan oo mishiinno bir ah oo iibiya mashiinnada jarista laysarka tuubada birta ah.

Laakiin si loo helo mashiinka jarista laysarka ee tuubo bir ah oo tayo wanaagsan leh, waxaa loo baahan yahay khibrad wanaagsan oo ku saabsan wadada iftiinka, wadada korontada, wadada biyaha, iyo tiknoolajiyada jarista laysarka 3D. Kaliya iskuma koobna.

Golden Laser waxay leedahay 18 sano oo waayo-aragnimo ah oo ay ku soo saarto mashiinno tayo wanaagsan leh oo joogto ah oo ku saabsan jarista tuubada laser-ka fiber-ka, khibrad qani ah oo ku saabsan mashiinnada jarista laser-ka tuubada birta ah, iyo koox adeeg kadib si loo hubiyo khibrad isticmaale oo wanaagsan oo ku saabsan mashiinka jarista tuubada laser-ka birta ah.

#6 Adeeg-bixin Iibka Kadib

Golden Laser waxay mashiinka jarista laysarka u dhoofisaa in ka badan 100 waddan iyo magaalooyin kala duwan.

Waxaad si toos ah u hubin kartaa tayada mashiinkayaga maxalliga ah oo aad ku raaxaysan kartaa albaab albaab ah waqtiga adeegga ka dib adiga oo adeegsanaya wakiilkeena ama warshadda.