Thola Umshini Wokusika I-Laser Tube Ofanele Kakhulu

CELA ISITHELO SOKUTHOLA IMINININGWANE ENGEZIWE

Konke Okufanele Ukwazi Ngomshini Wokusika Amashubhu E-Laser ngo-2024

Umshini wokusika ishubhu le-laser uhlobo olulodwa lomshini wokusika i-laser yefayibha osika kuphela amashubhu nezinto zensimbi ezahlukene (insimbi engagqwali, insimbi yekhabhoni, ithusi, iphrofayili ye-Aluminium),kuhlukile kwiamanye amathuluzi okusika amapayipi, iyi-ukungathintiindlela yokusika enembile kakhulu, kunjaloakukho ukuhlanekezelangesikhathi sokukhiqiza.

Kulula ukusikaimiklamo eyinkimbinkimbiepayipini kanye nokubhobozwa okunembe kakhulu ngumsiki wepayipi le-laser.

Kululashintsha umklamo wakho wokukhiqizaindlela kusilawuli se-laser se-CNC esihlakaniphile.

Kwenziwe ngezifisoUChuck Hlangana neThubhu Ehlukile kanye nobubanzi bephrofayela kanye nesisindo ukuqinisekisa umphumela omuhle wokusika i-laser

KuyiniInzuzo Yemishini Yokusika I-Laser Tube?

1. Ifanela Amapayipi Amaningi Anesimo Esifanayo

Amapayipi ayindilinga, ayisikwele, ayisikwele, kanye namanye akhethekile, i-Channel Steel, i-I Beam, i-Profile, njalo njalo.

2. Ukubhoboza Okusebenza Kakhulu

Ukunemba okuphezulu okungaba ngu-0.1m, kulula ukusika noma yimuphi umklamo oyinkimbinkimbi ikakhulukazi ukubhoboka emsebenzini wokusika amapayipi.

3. Akukho Ukucindezela Ebusweni Bensimbi

Ukusika nge-laser kuyindlela yokusika engadingi ukuthintwa eshisa kakhulu, ngeke icindezele izinto, futhi akukho ukuphambuka ekukhiqizweni.

4. Ukushisela Ipayipi Qaphela

Qaphela futhi ugweme izintambo zokushisela ukuze unciphise ukuphuka ngesikhathi sokusika nge-laser.

Umshini Wokusika I-Laser Tube Wokukhiqiza Izingxenye Eziyinhloko

Ungayisebenzisa Kanjani Imishini Yokusika I-Laser Tube?

Indlela yokusebenza komshini wokusika ishubhu le-laser injena ngokuyinhloko.

1. Faka ithubhu elinomumo ofanele kusofthiwe ye-laser tube Nesting (Lanteck),

Setha ipharamitha yokuklama yokusika efanele ngokuya ngobukhulu bensimbi nohlobo lwensimbi, insimbi ethambile, insimbi engagqwali, i-Al, ithusi, njalo njalo.

2. Thumela ifayela kusilawuli somshini wokusika ishubhu ye-laser,

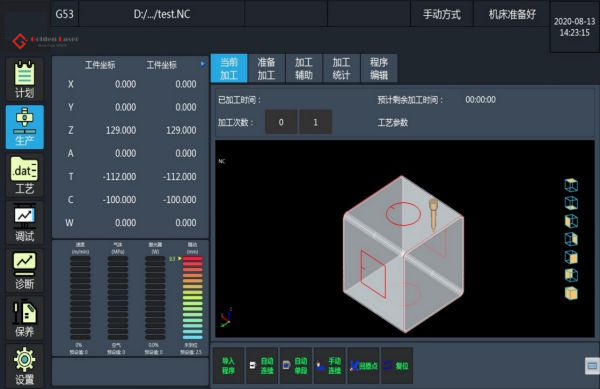

Zonke izinhlobo zensimbi ezijwayelekile zizobonisa isimo se-3D esikrinini sokusebenza, ungahlola kabili umklamo ngokucacile.

3. Ukulayisha ishubhu elifanele emshinini wokusika ishubhu le-laser (Ukulayisha ngesandla noma okuzenzakalelayo ngokuzikhethela),

Ngohlelo lokulayisha oluzenzakalelayo, akudingeki ukhathazeke ngethubhu elingalungile elihlanganiswe nenqwaba yamathubhu, lizolinganisa ngokuzenzakalelayo noma lizokwethusa uma ungakawubeki umsebenzi wokusika ingxube ohlelweni lokusika.

4. Qala umshini wokusika ishubhu le-laser bese uqoqa ishubhu lensimbi eliqediwe.

Qiniseka ukuthi i-water chiller kanye ne-air compressor zivuliwe ngaphambi kokucindezela inkinobho ethi "qala", i-tailer yepayipi izolandela iye ebhokisini lokuqoqwa kwemfucuza ngaphansi kwephansi lomshini, futhi izingxenye eziqediwe zizothunyelwa etafuleni lokuhambisa ukuze kuhlanganiswe ibhokisi.

Kungani Ukhetha Umshini Wokusika I-Steel Laser Tube?

Izinto Okufanele Uzicabangele Lapho Uthenga Umshini Wokusika I-Laser Tube

#1 Buyini Ubukhulu Obuyinhloko Okufanele Ubunqume?

Kubalulekile ukukhetha umshini wokusika insimbi we-laser ofanele ngamandla e-laser ngoba amandla e-laser ahlukene intengo izohluka kakhulu.

Khetha ngokuya ngobukhulu obukhulu, ukutshalwa kwezimali kuzodlula kalula isabelomali sakho.

#3 Udinga Ukuxhumana Nesistimu Ye-ERP Noma Cha?

Cabanga ngesimo sakho sefektri bese ukhetha isilawuli se-laser esifanele kuzoba ukukhetha okuhle.

Uma kungekho sidingo sokuxhuma izinhlelo ze-ERP neminye imishini yokugaya, isilawuli saseShayina i-FSCUT sizoba ukukhetha okuhle, isikhombikubona esinobungane futhi kulula ukusisebenzisa.

#4 Ukuqonda Isidingo Sesicelo Semboni

Umshini wokusika we-laser owusizo uklanyelwe ngokwesidingo samakhasimende esinemininingwane, imisebenzi eminingi yenziwa ngezifiso ngemva kokutadisha ngokujulile ekutholakaleni komkhiqizo kwamakhasimende.

Okuhlangabezana nesidingo esingaba khona futhi okwenza kube lula futhi kwandise ukusebenza kahle komugqa wokukhiqiza.

Ikhono eliqinile le-R&D libalulekile uma uthola abakhiqizi bemishini yokusika ishubhu le-laser yensimbi.

#2 Udinga Ukubumba Amapayipi Ensimbi?

Ukuze uthole ishubhu lensimbi elinomumo ojwayelekile, kulula ukulisika, njengesiyingi, isikwele, kanye nesikwele.

Uma kudingeka ukusika amapayipi anomumo, njenge-Channel Steel, i-I beam, amapayipi ohlobo lwe-C kungcono uhlole nochwepheshe ukuqinisekisa ukuthi ithini lisikiwe ngokuphindwe kabili.

#5 Ikhwalithi Yomshini kanye Nokuhlangenwe Nakho Kwasefekthri

Njengoba intengo yomthombo we-laser yehla kakhulu, kunezimboni eziningi zemishini yensimbi ezithengisa imishini yokusika i-laser yeshubhu yensimbi.

Kodwa ukuze uhlinzeke ngomshini wokusika i-laser weshubhu yensimbi osezingeni elihle, udinga ulwazi oluhle ngomzila wokukhanya, umzila kagesi, umzila wamanzi, kanye nobuchwepheshe bokusika i-laser ye-3D. Awugcini nje ngokuhlanganisa.

IGolden Laser ineminyaka engu-18 yesipiliyoni ekukhiqizeni imishini yokusika ishubhu le-fiber laser esezingeni elihle nelizinzile, ulwazi olucebile ngemishini yokusika ishubhu le-laser yensimbi, ithimba elisebenza ngesikhathi ngemuva kwenkonzo ukuqinisekisa ulwazi oluhle lomsebenzisi womshini wokusika ishubhu le-laser yensimbi.

#6 Ukusebenziseka Ngemva Kokuthengisa

I-Golden Laser ithumela umshini wokusika i-laser emazweni nasemadolobheni angaphezu kwe-100 ahlukene.

Ungahlola ikhwalithi yomshini wethu endaweni yakini futhi ujabulele umnyango nomnyango ngesikhathi ngemuva kwesevisi nge-ejenti yethu noma ifektri ngqo.