Imishini yokusika amashubhu e-laser yenza okungaphezu kokusika izici eziningi ezinhle futhi ihlanganise izinqubo. Iphinde isuse ukuphathwa kwezinto kanye nokugcinwa kwezingxenye eziqediwe, okwenza isitolo sisebenze kahle kakhulu. Kodwa-ke, lokhu akupheleli lapho. Ukukhulisa imbuyiselo ekutshalweni kwemali kusho ukuhlaziya ngokucophelela imisebenzi yesitolo, ukubukeza zonke izici zomshini ezitholakalayo kanye nezinketho, nokucacisa umshini ngokufanele.

Kunzima ukucabanga ngokufinyelela ukusika amashubhu okuhle kakhulu—kungakhathaliseki ukuthi izinto zokusebenza ziyindilinga, ziyisikwele, ziyisikwele, noma azilingani—ngaphandle kwama-laser. Izinhlelo ze-laser zashintsha inqubo yokusika amashubhu, ikakhulukazi maqondana nokwakheka okuyinkimbinkimbi. Umshini onjalo udinga ukutshalwa kwezimali okukhulu kokuqala, ikakhulukazi uma usebenza ngamashubhu amakhulu futhi wethula ukuzenzekela kanye nobunye ubuchwepheshe obusha enkambisweni yokukhiqiza, ngakho kuzodingeka uhlele ngokucophelela ukuqinisekisa ukuthi ukusika amashubhu e-laser kuyabiza kakhulu enkampanini yakho.

Ekugcineni, udinga ukucabangela iziguquguquko eziningana ngaphambi kokunquma ukuthenga i-umshini wokusika ishubhu le-laserukwakheka komkhiqizo, ukwenza lula inqubo, ukunciphisa izindleko, kanye nezikhathi zokuphendula kuphakathi kwezinto ezibaluleke kakhulu.

Izici zomkhiqizo

Ukusikwa kwe-laser kungazivumela ukuthi kuklanywe imikhiqizo emisha ngokuphelele. Imiklamo emisha neyinkimbinkimbi kulula ukuyicubungula nge-laser futhi ingenza umkhiqizo ube namandla futhi uthandeke kakhudlwana, ngokuvamile wehlisa isisindo ngaphandle kokudela amandla. Ama-laser e-tube ayazigqaja ekusekeleni inqubo yokuhlanganiswa kwe-tube. Izici ezikhethekile zokusika kwe-laser ezivumela amaphrofayili e-tube ukuthi agobe noma ahlanganiswe kalula zingenza kube lula ukushisela nokuhlanganisa kakhulu futhi zisize ukunciphisa izindleko zomkhiqizo.

I-laser ivumela umqhubi ukuthi asike imigodi kanye nemigqa ngokunembile ngesinyathelo esisodwa sokusebenza, asuse ukuphathwa kwezingxenye okuphindaphindiwe kwezinqubo ezingezansi komfula (bheka uMfanekiso 3). Esibonelweni esisodwa esithile, ukwenza uxhumano lweshubhu ne-laser esikhundleni sokusika, ukugaya, ukubhoboza, ukususa imfucuza, kanye nokuphathwa kwezinto ezihambisanayo kunciphisa izindleko zokukhiqiza ngamaphesenti angu-30.

Ukuhlela okulula okuvela kumdwebo womklamo osizwa yikhompyutha kwenza kube nokwenzeka ukuhlela ingxenye ngokushesha yokusika nge-laser, noma ngabe kungokokukhiqiza ngamaqembu amancane noma ukwenza ama-prototyping. Akukhona nje kuphela ukuthi i-tube laser ingacubungula izingxenye ngokushesha, kodwa nesikhathi sokusetha sincane, ngakho-ke ungenza izingxenye ngesikhathi esifanele ukuze unciphise izindleko zempahla.

Ukufanisa Umshini Nezinhlelo Zokusebenza

Ngemva kokubhala uhlu lwezinyathelo zakho zokukhiqiza ezivamile, isinyathelo sakho esilandelayo ukubukeza izici ezitholakalayo bese unquma ukuthi yiziphi ezibalulekile.

Amandla Okusika. Khumbula ukuthi ama-laser amaningi eshubhu afakwe ama-resonator aletha amandla okusika angu-2 KW kuya ku-4 kW. Lokhu kwanele ukusika ubukhulu obujwayelekile obukhulu beshubhu yensimbi ethambile (5⁄16 intshi) kanye nobukhulu obujwayelekile obukhulu beshubhu ye-aluminium nensimbi (¼ in.) ngempumelelo. Abakhiqizi abacubungula inani elikhulu le-aluminium nensimbi engagqwali bazodinga umshini osezingeni eliphezulu lebanga lamandla, kanti izinkampani ezisebenza ngensimbi ethambile elinganisiwe cishe zingaphumelela ngeyodwa esezingeni eliphansi.

Umshini wethu wokusika amashubhu e-laser P3080 3000w wokucubungula amashubhu e-Australia

Umthamo. Umthamo womshini, ovame ukulinganiselwa ngesisindo esiphezulu ngonyawo, ungenye into ebalulekile okufanele uyicabangele.

Amashubhu eza ngobukhulu obuhlukahlukene obujwayelekile, ngokuvamile kusukela kumamitha angu-20 kuya kwangu-30 futhi ngezinye izikhathi ande. Umkhiqizi wemishini yokuqala noma umkhiqizi wenkontileka u-oda ishubhu ngobukhulu obujwayelekile ukuze anciphise izinsalela ngakho-ke kufanele acabangele umshini ohambisana nobukhulu bezinto ezivamile. Ukukhetha kuba nzima kakhulu ezitolo zemisebenzi. Amashubhu avela emshinini ngokuvamile amamitha angu-24 ubude ububanzi obufika ku-6 amayintshi kanye no-30 ubude bamaphrofayili ububanzi obufika ku-10 amayintshi. Kulolu hlu losayizi, isisindo esijwayelekile sohlelo lwe-tube laser singafinyelela kumakhilogremu angu-27 ngenyawo eliqondile.

Umthwalo Nokuthulula Izinto. Esinye isici ekukhetheni komshini yikhono lawo lokudla ngezinto ezingavuthiwe. Umshini we-laser ojwayelekile, osika izingxenye ezijwayelekile, usebenza ngokushesha kangangokuthi izinqubo zokulayisha ngesandla azikwazi ukuhambisana, ngakho-ke imishini yokusika i-tube laser ivame ukuza ne-bundle loader, elayisha izinqwaba zezinto ezingamakhilogremu angu-8,000 kumagazini. I-loader ihlukanisa amashubhu bese iwalayisha ngalinye ngalinye emshinini. I-bundle loader ingaletha namashubhu amaningi angavuthiwe kumagazini we-buffer ukuze kuncishiswe izikhathi zokulayisha phakathi kwamashubhu kube yimizuzwana eyi-12. Ukushintsha kusuka kosayizi weshubhu elilodwa kuya kwelinye kwenziwa kube lula yindlela ezenzakalelayo ngaphakathi kwe-loader. Zonke izinguquko ezidingekayo zosayizi weshubhu elisha ziphathwa yisilawuli.

Uma kudingeka ukuphazamisa ukukhiqiza okukhulu komsebenzi omncane, kusabalulekile ukuba nezinketho zokulayisha ngesandla. Umqhubi umisa ukukhiqiza, alayishe ngesandla futhi acubungule amashubhu ukuze aqedele umsebenzi omncane, bese eqala kabusha ukukhiqiza. Ukukhipha umthwalo nakho kuyadlala indima. Uhlangothi lokukhipha umthwalo lwemishini yamashubhu aqediwe luvame ukuba ngamafidi ayi-10 ubude kodwa lungandiswa ukuze luvumelane nobude bezingxenye eziqediwe ezizocutshungulwa.

Ukutholwa Komthungo Nokuma. Amashubhu ahlanganisiwe asetshenziswa emikhiqizweni ekhiqiziwe kakhulu kunamashubhu angenamthungo, futhi umthungo wokushisela ungaphazamisa inqubo yokusika nge-laser kanye nokuhlanganiswa kokugcina. Umshini we-laser ohlome ngehadiwe efanele ngokuvamile ungabona imithungo ehlanganisiwe ngaphandle, kodwa ngezinye izikhathi ukuphela kweshubhu kufihla umthungo. Uhlelo olujwayelekile lokuzwa umthungo lusebenzisa amakhamera amabili kanye nemithombo yokukhanya emibili ukuze lubheke ingaphandle nangaphakathi kweshubhu ukuze lubone umthungo wokushisela. Ngemva kokuba uhlelo lokubona luthole umthungo wokushisela, isofthiwe yomshini kanye nohlelo lokulawula lujikeleza ishubhu ukuze kuncishiswe umthelela womthungo wokushisela kumkhiqizo oqediwe.

Izinhlelo eziningi ze-tube laser zingasika amapayipi ayindilinga, ayisikwele, nangunxande, kanye namaphrofayili afana nokwakheka kwe-teardrop, i-angle iron, kanye ne-C-channel. Amaphrofayili angalingani angaba nzima ukulayisha nokubopha kahle, ngakho-ke ikhamera ekhethekayo efakwe ukukhanya okukhethekile ihlola ipayipi ngesikhathi senqubo yokulayisha futhi ilungise i-chuck ngokuya ngephrofayili etholiwe. Lokhu kuqinisekisa ukulayishwa okuthembekile nokusikwa kwamaphrofayili angalingani.

Ikhanda Lokusika. Ukusika i-bevel kubalulekile ekuhlanganiseni amashubhu okusika ndawonye ukuze kushiselwe. Ukusika i-bevel kudinga ikhanda lokusika elithambekela kuma-degrees angu-45 kunoma iyiphi indlela ngesikhathi senqubo yokusika. Ukuze uthole ukuphepha okwengeziwe kokucubungula ngesikhathi senqubo yokusika i-bevel eyinkimbinkimbi, ikhanda lokusika lingavikelwa ngamamagnethi. Uma kwenzeka ukushayisana phakathi kwengxenye yokusebenza yeshubhu nekhanda, ikhanda liyahlukana; lingaxhunywa kabusha ngemizuzwana embalwa nje. Kungenzeka futhi ukuhlanganisa ikhanda lokusika i-bevel ne-axis eyengeziwe yesivinini esikhulu ukuze kuthuthukiswe ukusheshisa ukusika, okuvumela ukwanda kokukhiqiza kwemishini kufinyelela kumaphesenti angu-30.

Ukukhulisa Ukusebenza Kahle

Ngemva kokuthola inani uhlelo lokusika ishubhu le-laser olungaliletha enqubweni yokukhiqiza, udinga ukulungisa leyo mishini yesicelo sakho. Isibonelo, ukufushane kakhulu kohlelo lokulayisha kungathinta kakhulu ukusebenza kahle kokwakha izidleke zezingxenye eziqediwe, okwandisa udoti, kuyilapho uhlelo olude kakhulu luzodinga ukutshalwa kwezimali kokuqala okuphezulu kanye nesikhala esingaphezulu kwesidingekayo. Ngaphezu kokufuna iseluleko kubakhiqizi bohlelo, kuzodingeka usike izingxenye zesampula futhi uhlole zonke izinketho ezitholakalayo ukuqinisekisa ukuthi ukutshalwa kwezimali kwakho kuphumela ekubuyiselweni okungcono kakhulu.

Umsiki We-Laser Wepayipi Kusayithi Lethu Lamakhasimende

Umsiki Wepayipi We-Fiber Laser Tube 3000W P3080 Wokucubungula Amapayipi EFrance

Umshini Wokusika Ipayipi Le-Fiber Laser Loader Ozenzakalelayo P3080A E-USA

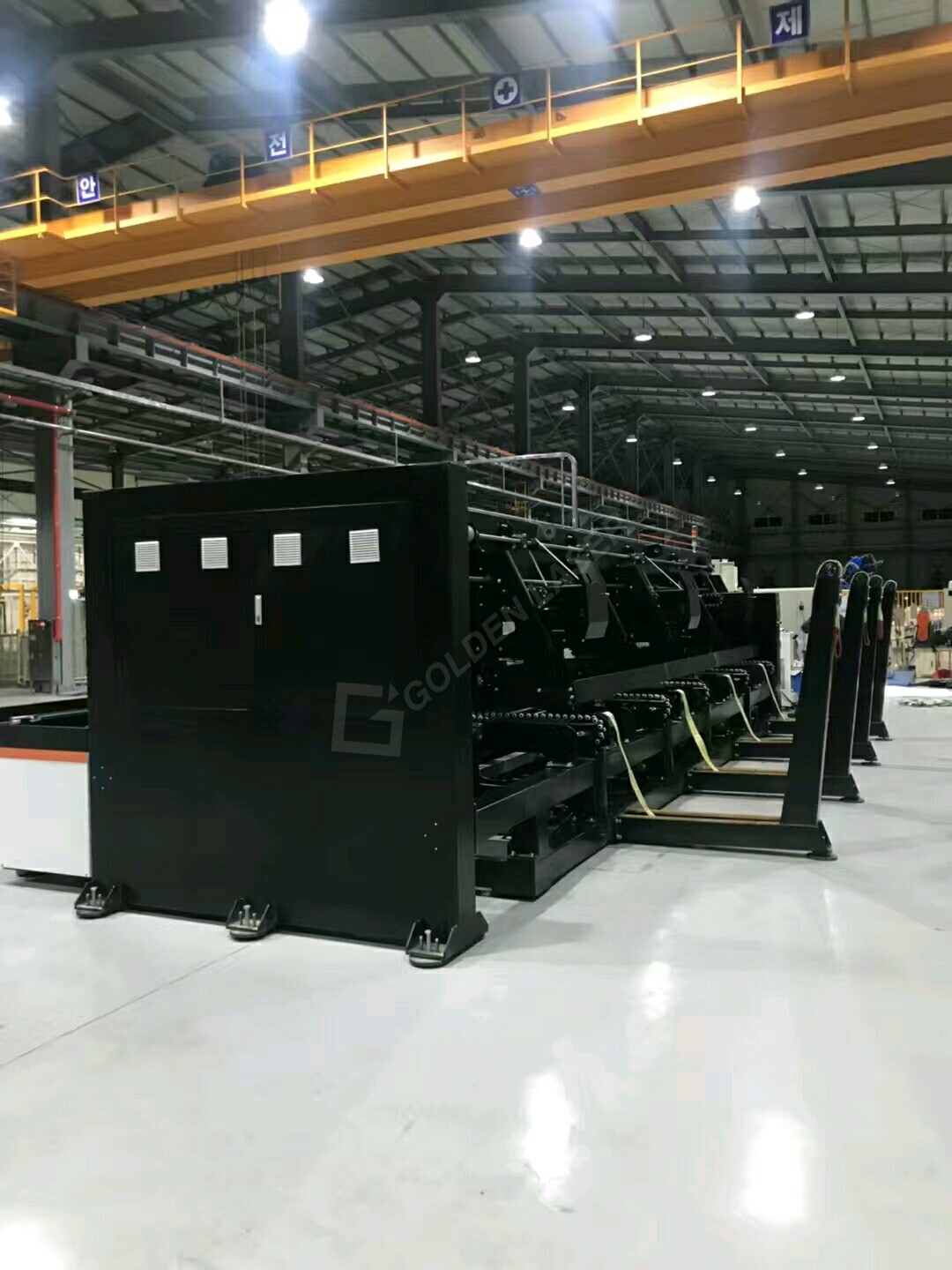

Isethi Ezine Zokusika Ipayipi Le-Laser P2060A Yefenisha Yensimbi EKorea

Umshini Wokusika I-Tube Laser P2060A Wokucubungula Amapayipi EMexico

Umshini Wokusika Ipayipi Nge-Laser P3080 Wokucubungula Amapayipi EFrance

Umshini Wokusika I-Laser Wepayipi Eliphelele we-Cnc Professional Pipe P2060A eTaiwan

Isisiki Se-Laser Se-Fiber Pipe esenziwe Ngokwezifiso P2080A EKorea

Umshini Wokusika I-Laser We-P30120 Metal Tube Wesakhiwo Sensimbi EShayina