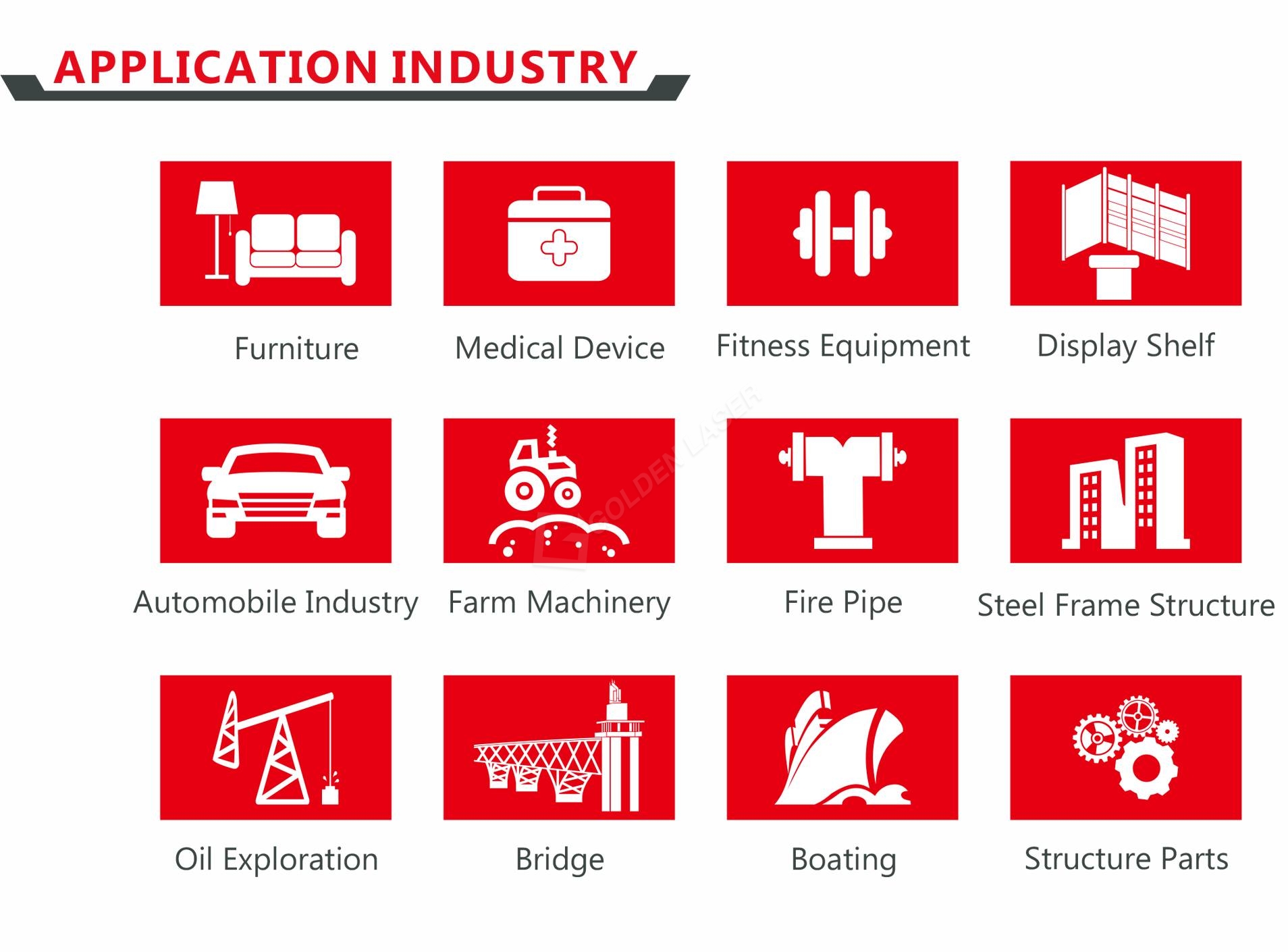

Tare da ci gaba da ci gaban al'umma, mutane suna neman ƙari da kuma kayan aikin motsa jiki, da kuma kayan aikin motsa jiki ne wanda mutanen da ke bin rayuwar lafiya da na gaye su ne sau da yawa. Tare da overurge a cikin dacewa, buƙatar kayan aikin motsa jiki ya karu sosai. Hanya ta fiber Laser yankan mashin da kuma sassauƙa hanyar yankan yankewa ta hadu da wannan bukatar sosai.

A ci gaba da fadada daga cikin tawagar motsa jiki ya kawo damar kasuwanci mai karfi don kayan aikin motsa jiki. Yawancin kamfanonin motsa jiki da yawa suna ci gaba da halin ci gaba na kasuwa, haɓaka ƙa'idar fasaha, haɓaka fasahar samarwa da haɓaka masana'antar samfuri da haɓaka samfur.

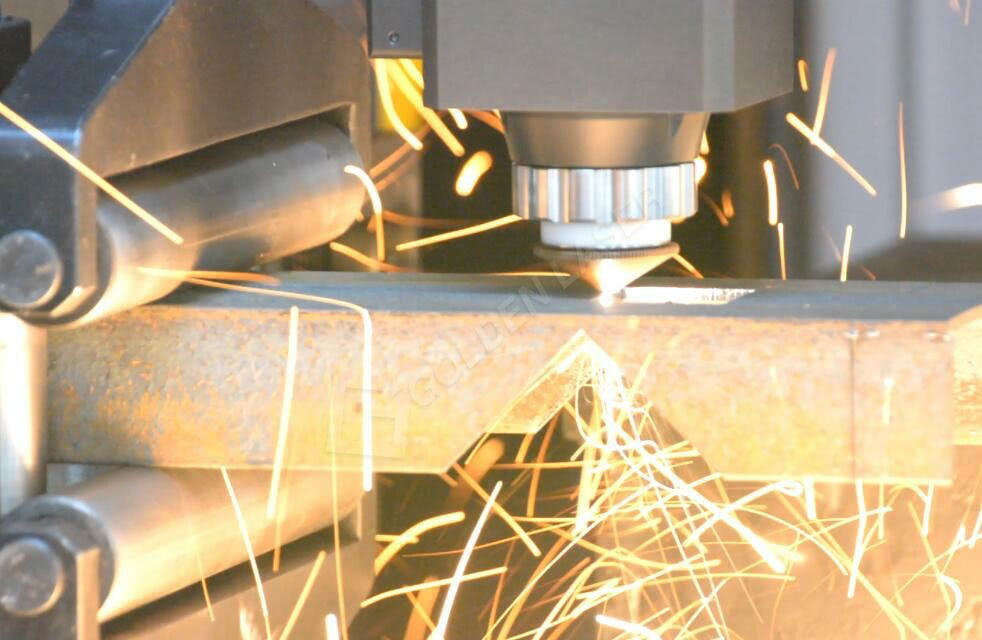

Fiber Laser yanke yankan, fasahar da aka samar da fasahar-yankakken karfe a cikin masana'antun kayan aikin motsa jiki, ana amfani dashi sosai a wannan masana'antar. Idan aka kwatanta da tsarin gargajiya na gargajiya na gargajiya, wanda ke buƙatar yankan, blanking, da lanƙwasa, mashin da yawa na molds na cinye, amma injin yankan molds ba ya buƙatar wucewa ta cikin waɗannan hanyoyin da zai iya yanke aikin da inganci mai kyau.

Halayenta galibi suna bayyana a:

1. Babban daidaito: Yankunan bututun gargajiya na gargajiya na gargajiya yana ɗaukar hanyar da hannu, saboda haka kowane yanki na yankan ya bambanta. Injin bututun lau da aka yanke na'urorin da aka yi amfani da tsarin tsayuwa iri ɗaya, an kammala software mai sarrafawa ta hanyar shirye-shiryen kwamfuta, saboda haka madaidaicin madaidaicin aiki yana da girma sosai.

2. High efficiency: A pipe laser cutting machine can cut several meters of pipe in one minute, more than hundreds of times quicker than the traditional manual mode, which means the laser processing has high efficiency.

3. Waƙaƙe: Motocin bututu laerch yanke don sassauci tsari daban-daban, don haka mai zanen zai iya yin zane mai rikitarwa wanda bai dace ba a ƙarƙashin hanyoyin sarrafa na gargajiya.

4. Gudanar da Batch: Tsarin bututu mai lamba 6. Hanyar sarrafa ta gargajiya tana buƙatar ƙamshi mai yawa, amma ƙwayar bututun Laser yanka tana iya cika bututun mai sauƙi da sauri, wanda ke sa aikin tsari ya zama mai yiwuwa.

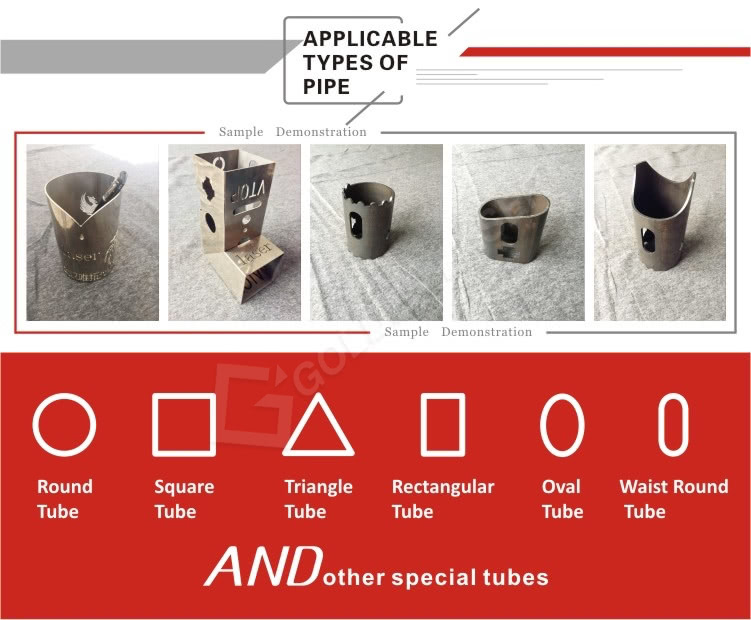

Bugu da kari, laseran laser iya kammala yankan da kuma nau'i a cikin kayan kwalliya na gargajiya ko na musamman kamar su, da sauransu, da kuma yin sabani mai tsari na tsari, wanda yake Ba a iyakance ga zane-zane masu rikitarwa ba, kuma bayan yankan sashin bututun ba zai buƙaci aiki na sakandare ba, yana iya taƙaita darajar samarwa kai tsaye, da rage darajar samarwa da kuma samar da iyaka mara iyaka ga kamfanin.

Proderia Golden Laser P jerin na'ura ta atomatikZai iya yanke zagaye, murabba'i, murabba'i, da sauran bututun da aka tsara tare da babban yankan da yawa. Idan aka kwatanta da yankan gargajiya, yankan Laser ya fi sassauƙa, ba tare da buƙatar gina ƙirar ba, don haka yana adana sabon lokacin haɓaka samfurin sosai. Tunda, saurin yankewa da daidaito suna da girma sosai, don haka yana iya adana farashi da inganta inganci.

PIPE Laser Yanke kayan aikin injin:

Tsarin Ciyar da atomatik: bututun zagaye, bututun zagaye, bututun mai na rectangular, da sauransu. Za'a iya taimaka wa Tambo da hannu tare da ciyar da atomatik.

Cibiyar Kula da Chuck: Cibiyar Chuck Daidaitawa ta atomatik ta daidaita karfi ta atomatik gwargwadon bayanan bayanan, saboda haka zai iya tabbatar da kumburin bututun mai ba tare da lalacewa ba.

● Kullun Kullum Raping Tsarin: Saurin amsawa na kusurwa yana da sauri sosai kuma yana inganta yankan inganci.

Ingantaccen Yankan Tsarin: Bayan yankan, ana iya ciyar da aikin motsa jiki ta atomatik ga yankin ciyar da shi.

PIPE Laser Cutter don kayan aikin motsa jiki a cikin rukunin abokin ciniki