Umonakalo wemitha yelaser emzimbeni womntu ubangelwa ikakhulu yimpembelelo yobushushu belaser, impembelelo yoxinzelelo lokukhanya kunye nempembelelo ye-photochemical. Ngoko ke amehlo kunye nolusu zezona zinto zibalulekileyo zokukhusela. Uhlu lweengozi zemveliso yelaser luluhlu oluchaziweyo oluchaza inqanaba lomonakalo obangelwe yinkqubo yelaser emzimbeni womntu. Kukho amanqanaba amane, ilaser esetyenziswa kumatshini wokusika ilaser yefayibha ikwiklasi yesi-IV. Ke ngoko, ukuphucula inqanaba lokhuseleko lomatshini akusiyo nje indlela yokukhusela esebenzayo kubo bonke abasebenzi abafuna ukufikelela kolu hlobo loomatshini, kodwa ikwanoxanduva kwaye inentlonelo kubasebenzi abasebenzisa lo matshini. Ngoku amandla elaser omatshini wokusika ilaser yefayibha aya enyuka, ukusuka kumatshini wokuqala wokusika ilaser we-500W ukuya kumatshini wokusika ilaser we-15000W, ukukhula ngokukhawuleza kwamandla elaser kwenza ukhuseleko lwelaser lube lubaluleke ngakumbi.

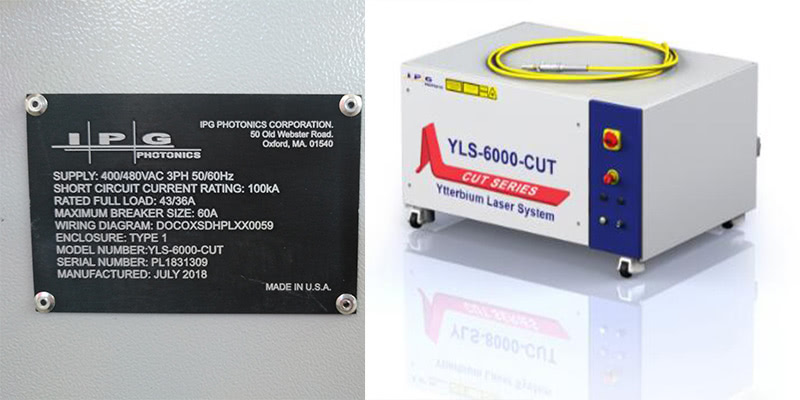

Umthombo welaser we-IPG we-6000w

Yasekwa ngo-1992, iGolden laser yayisoloko igxile ekwenzeni oomatshini be-laser, kwaye idibanise uyilo lwemveliso ye-laser, ukwenziwa kwayo, ukuthengiswa kwayo kunye nenkonzo. Ukususela kwisicwangciso sokuqala soyilo lwemveliso, ingcamango yokhuseleko yaqala ukufakwa.umatshini wokusika i-laser yetafile ye-pallet evalwe ngokupheleleyoyaqaliswa kule ngcamango.

Izinto eziphambili zomatshini wokusika i-fiber laser ovalekileyo ngokupheleleyo

1. Uyilo olupheleleyo oluvaliweyo luqinisekisa ukugcinwa ngokukhuselekileyo kwenkqubo yokusika

Njengoko ubona kumfanekiso ongentla, ukhuselekile ngokupheleleyo xa ume phambi komatshini wokusika i-laser yefayibha yetafile ye-pallet evalekileyo ngokupheleleyo. Uyilo oluvalekileyo ngokupheleleyo luvumela zonke ii-laser ezibonakalayo ukuba zivalwe kwindawo evalekileyo. Okwangoku, ukuze kubonwe amandla okusika i-laser ngexesha langempela, iifestile zokujonga zenziwe ngaphambili nangasecaleni komatshini. Ifestile yokujonga isebenzisa imigangatho ephezulu yeglasi enganyangekiyo kwimitha, kwaye ifestile inkulu ngokwaneleyo ukuba ubone inkqubo yokusika. Nokuba awunazo iiglasi zokhuseleko ze-laser, ungazibamba ngokukhuselekileyo "ubuhle bokusika" kwe-laser.

Umatshini wokusika i-fiber laser onetafile yokutshintshana kwepallet

Ikhamera ye-2.High-definition ijonga ukucutshungulwa kokusika ngexesha langempela

Eyona nto ibalulekileyo kuyilo lwalo matshini kukuba sifake ikhamera ekumgangatho ophezulu kwi-engile efanelekileyo ngaphakathi kwendawo evalekileyo ukuqinisekisa ukuba umqhubi uyakwazi ukubona inkqubo yokusika nge-laser ngokucacileyo ngelixa esebenzisa umatshini. Okwangoku, ikhamera iya kubonisa isikrini sokujonga esicacileyo nesingalibazisiyo kwitafile yokusebenza, ukuze umqhubi akwazi ukwazi umatshini ongaphakathi nangona esebenzisa umatshini. Ukuba isixhobo sineemeko ezingaqhelekanga, umqhubi unokukwazi ukusiphatha ngempumelelo okokuqala ukuze aphephe ezinye iilahleko.

Inkqubo yokungenisa umoya ephezulu kumatshini yokuqokelela uthuli kunye nomsi

3. Inkqubo yokungenisa umoya ephezulu yomatshini yenza ukuba ikhuseleke kwindalo esingqongileyo

Ngexesha lenkqubo yokusika nge-laser, ingakumbi xa kusikwa intsimbi yekhabhoni kunye nentsimbi engatyiwayo, kuya kuvelisa umsi nothuli olunamandla. Ukuba akunakwenzeka ukususa le msi nothuli ngexesha elifanelekileyo, umsi omninzi oqokelelana ngaphakathi kumatshini uya kubangela indawo engabonakaliyo "yomsi" xa ujonge umatshini. Kwaye oku kusenokuba yiloo nto uxhalabileyo ngayo. Ngenxa yesi sizathu, besiyicingile kuyilo lomatshini. Uthuli nomsi osikayo uvuthuzwa yigesi ekusikeni, ngoko ke uya kusasazeka ngeendlela ezahlukeneyo kunye neendlela, kodwa uninzi lwawo luya kugxina embindini womatshini. Ngokwentshukumo nokuhamba komsi, umatshini wenzelwe inkqubo yokukhupha uthuli olunezigaba eziphezulu. Imingxunya yokuqokelela uthuli isasazwa phezu komatshini ngeefestile ezininzi kunye nokusasazwa, kwaye umatshini uxhotyiswe nge-wind turbine enkulu. Ke ngoko, ekusetyenzisweni kwangempela, isiphumo sokuqokelela uthuli silungile kakhulu.

Wakuba uwuqondile umatshini wethu wokusika i-laser yetafile ye-pallet evalekileyo ngokupheleleyo, kuya kufuneka ukwazi ukuqonda ukuba unokukunceda wenze ixabiso ngokukhuselekileyo ngelixa uwusebenzisa ukuphucula imveliso kunye nokusebenza kakuhle kwezoqoqosho.