Fumana Sekhahla sa Laser Tube se loketseng ka ho fetesisa

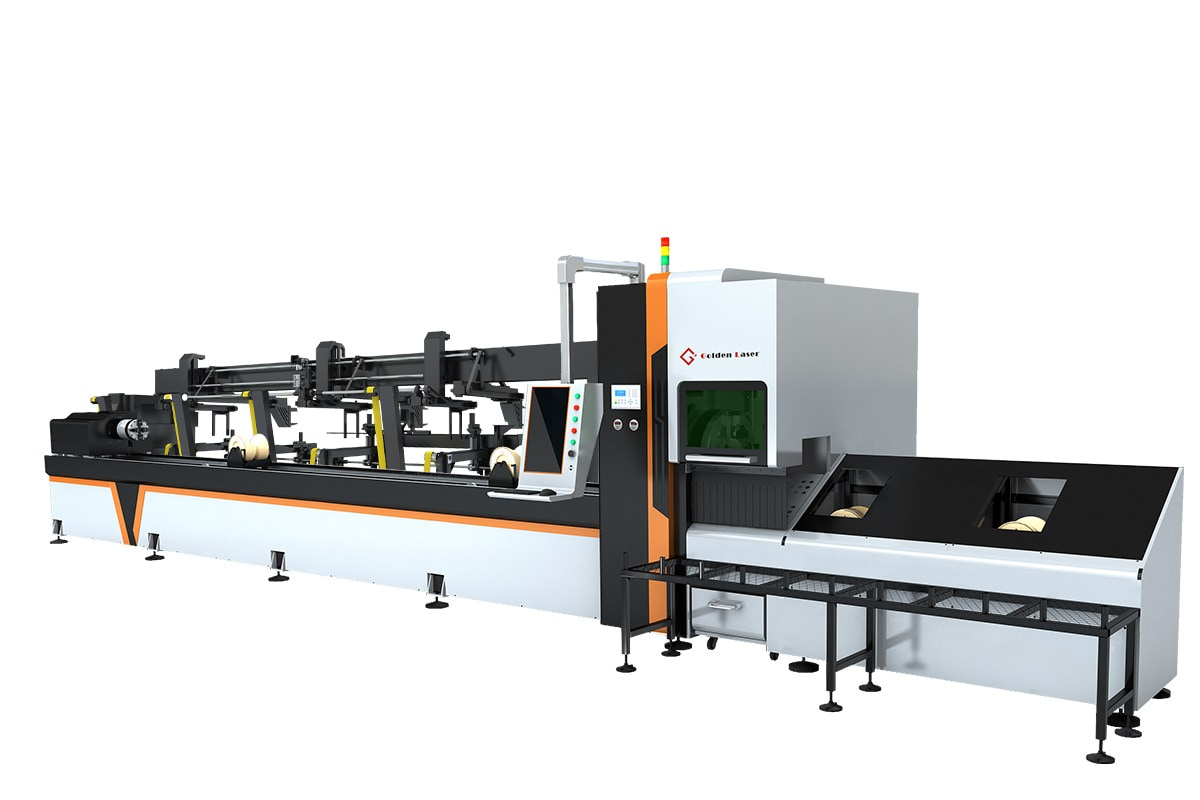

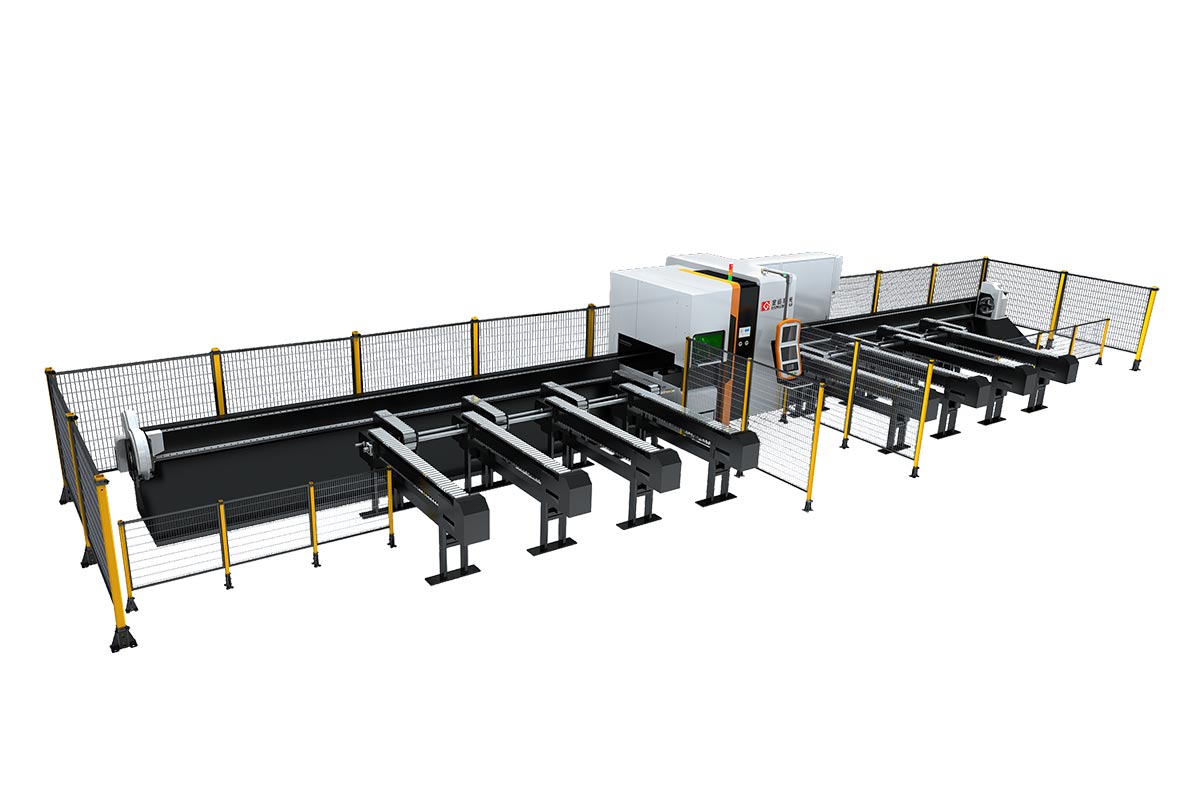

Letoto la F EcoFlex "F" ke mochini o sehang liphaephe tsa laser oa moruo, o tšoarellang nako e telele ebile o sebetsa haholo bakeng sa ho sebetsa liphaephe.

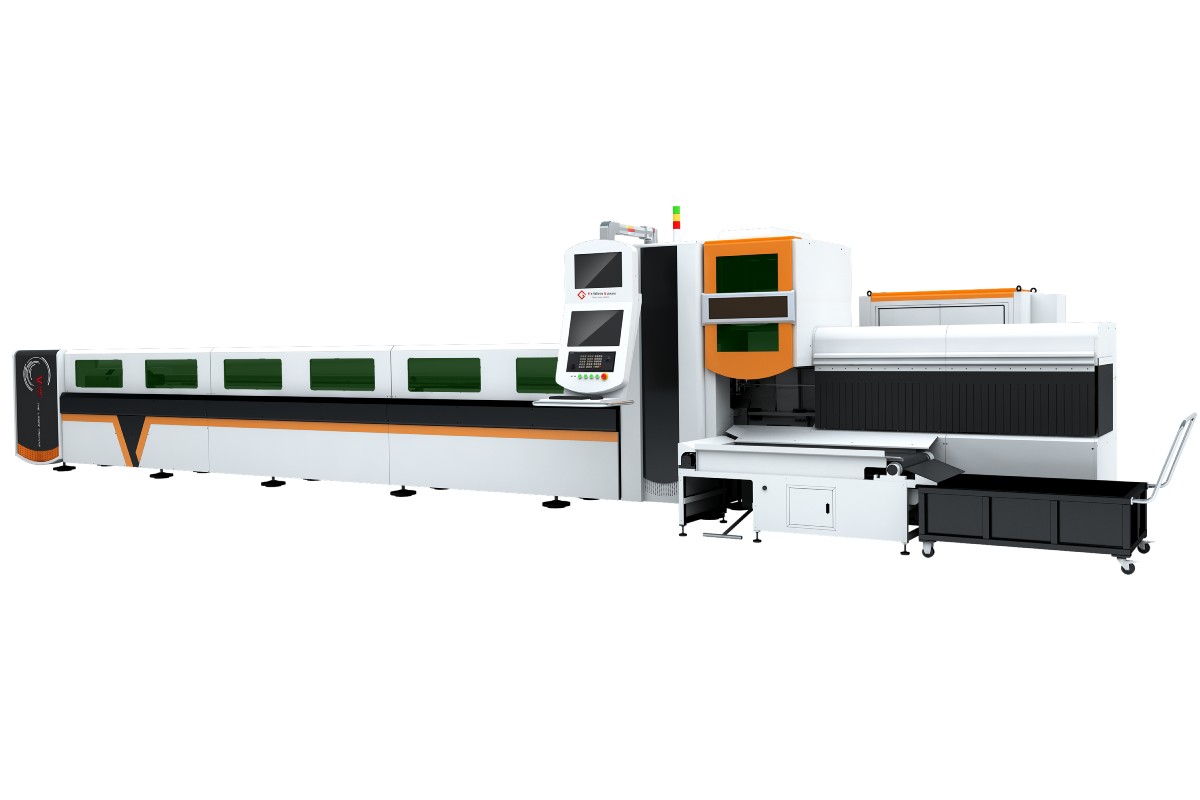

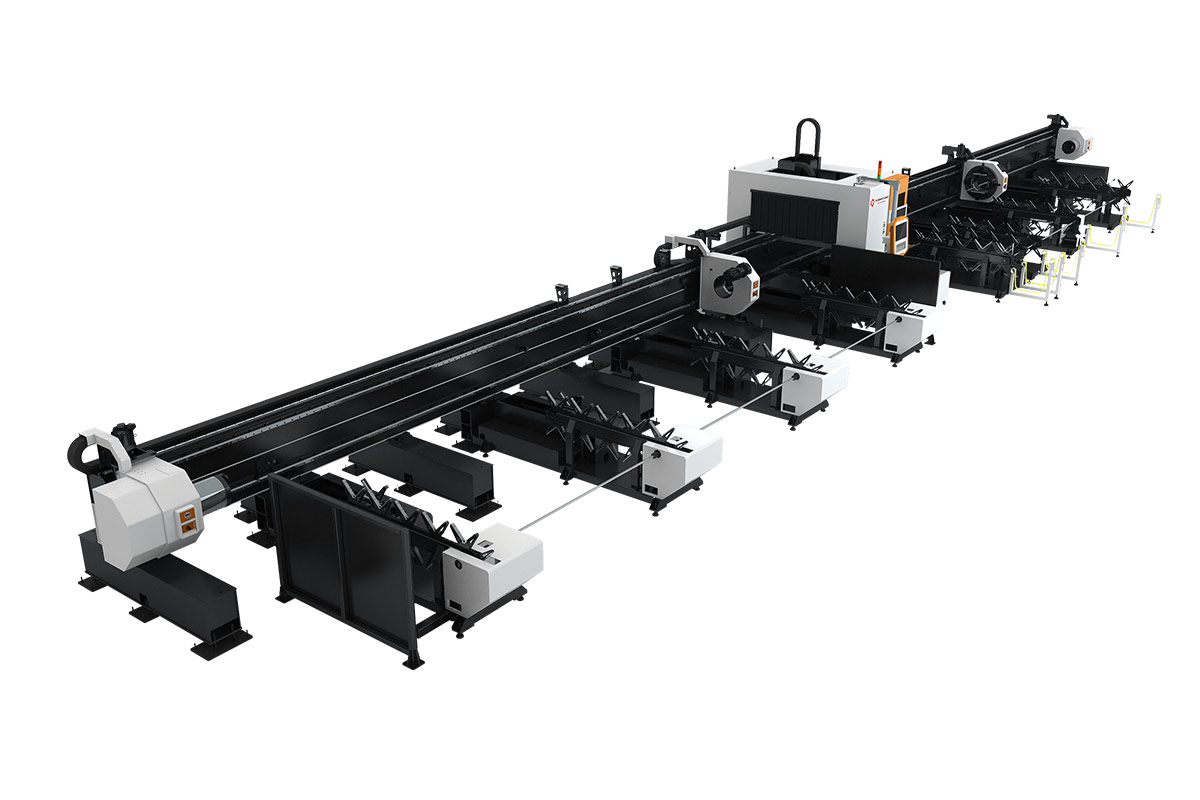

S letoto Smart "S" series ultra-small tube laser tube cutting machine ke mochini oa ho itšeha oa laser o etselitsoeng li-tubes tse nyane.E kopanya sistimi e bohlale ea taolo, tlhophiso e nyane ea li-tube clamping, ho fepa ka boiketsetso ka botlalo, ho itšeha le ho khutlisa morao ho fihlela ho itšeha ka lebelo le phahameng le ho nepahala ha li-tubes tse nyane.

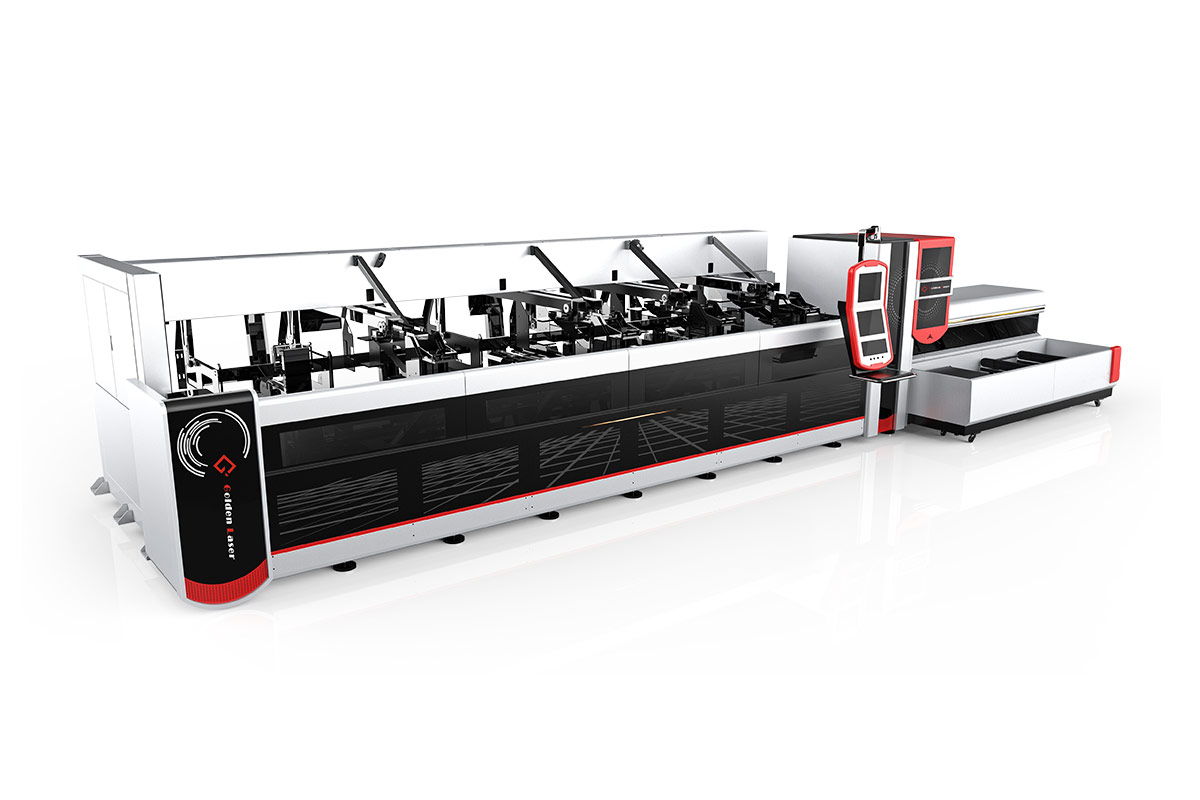

ke letoto Letoto la "I" la Intelligent ke mochine o bohlale, oa dijithale le o ikemetseng oa ho seha lipeipi tse phahameng tsa laser.

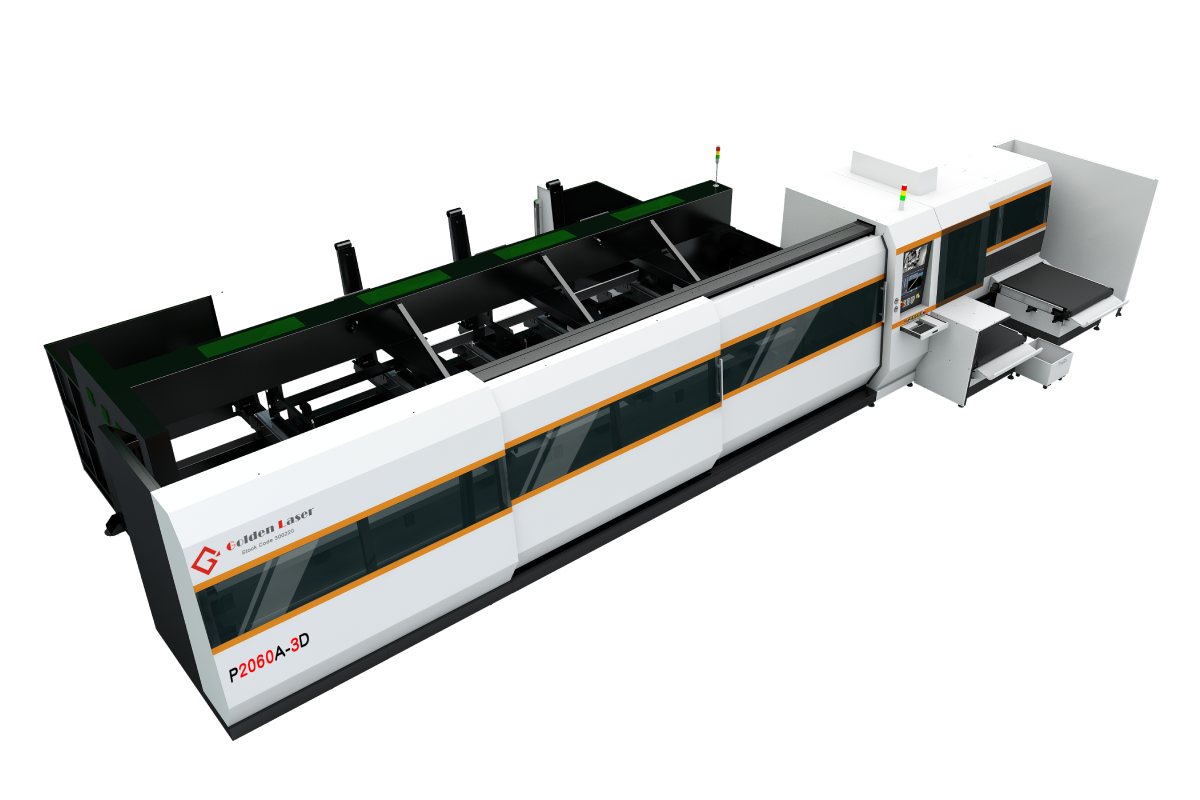

Letoto la Mega Letoto la MEGA ke mochini o sehang lipeipi tsa laser tse 3-chuck le 4-chuck tse ntlafalitsoeng ka ho khetheha bakeng sa lisebelisoa tsa laser cutting tsa liphaephe tse kholo, tse boima le tse telele.

KOPA QUOTE BAKENG SA LITABA TSE DING

Sohle seo U Lokelang ho se Tseba ka Mochini oa ho Seha Laser Tube ka 2024

Mochini oa ho itšeha ka laser tube ke mofuta o le mong oa mochini oa ho itšeha oa laser o fokotsang liphaephe tse fapaneng tsa lisebelisoa tsa tšepe le liphaephe (tšepe e sa hloekang, tšepe ea carbon, koporo, Aluminium Profile),fapaneng lelisebelisoa tse ling tsa ho seha lipeipi, ke aho se amemokhoa o phahameng o nepahetseng oa ho itšeha, ho joaloho se khopamenakong ya tlhahiso.

Ho bonolo ho khaolameralo e rarahanengholim'a tube le ho phunyeha ho phahameng ka ho nepahala ka laser tube cutter.

Ho bonolo hofetola moralo oa tlhahiso ea haumokhoa o bohlale oa CNC laser controller.

CustomizedChuck Kopana le Tube e fapaneng le Diameter ea Boemo le Boima ho netefatsa Sephetho se Seholo sa Laser Cutting

Ke eng eMolemo oa Mechini ea ho Seha Laser Tube?

1. Suit Liphaephe tse ngata tse bōpehileng

Round, Square, Rectangle, le liphaephe tse ling tse khethehileng tsa Shaped, Channel Steel, I Beam, Profile, joalo-joalo.

2. Phatlalatso e Phahameng ka ho Fetisisa

Ho nepahala ho phahameng hoo e ka bang 0.1m, ho bonolo ho khaola moralo ofe kapa ofe o rarahaneng haholo-holo oa ho phunya mosebetsing oa ho seha liphaephe.

3. Ha ho Khatello ho Metal Surface

Ho itšeha ka laser ke mokhoa o phahameng oa mocheso o se nang ho ama, o ke ke oa hatella lisebelisoa, 'me ha ho na ho sotha tlhahiso.

4. Pipe ea Welding Tseba

Lemoha le ho qoba mela ea tjheseletsa ho fokotsa ho robeha nakong ea ho itšeha ka laser.

Laser Tube Cutting Machine Manufacturing Parts Main

Mokhoa oa ho sebetsa Mechini ea ho Seha Laser Tube?

Mochine oa mochini oa ho itšeha oa laser tube o tšoana haholo le ona.

1. Kenya tšupu ea sebopeho se nepahetseng ho software ea laser tube Nesting (Lanteck),

Beha parameter e nepahetseng ea ho itšeha ho latela botenya ba tšepe le mofuta oa tšepe, tšepe e bonolo, tšepe e sa hloekang, Al, Brass, joalo-joalo.

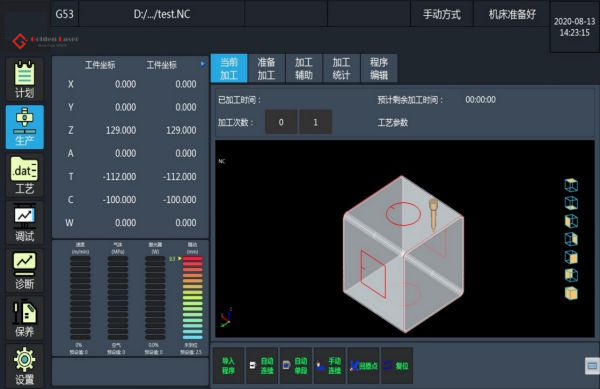

2. Romella faele ka har'a molaoli oa mochini oa seha oa laser tube,

Mefuta eohle e tloaelehileng ea li-tubes tsa tšepe e tla ba bontša sebopeho sa 3D skrineng sa ts'ebetso, o ka hlahloba moralo habeli ka ho hlaka.

3. Ho kenya tšupu e nepahetseng mochining oa ho itšeha oa laser (Ka letsoho kapa ka othomathiki ka khetho),

Ka mokhoa oa ho jarolla ka ho iketsa, ha ho hlokahale hore u tšoenyehe ka tube e fosahetseng e kopantsoeng hammoho le bongata ba li-tubes, e tla lekanya kapa e lla ha u e-s'o behe mosebetsi oa ho khaola motsoako lenaneong la ho itšeha.

4. Qala mochine oa ho itšeha oa laser tube 'me u bokelle tube ea tšepe e phethiloeng.

Etsa bonnete ba hore chiller ea metsi le compressor ea moea li bulehile pele u tobetsa konopo ea "qala", mohatla oa tube o tla latela lebokose la pokello ea litšila tlas'a mochine, 'me likarolo tse felile li tla romela tafoleng ea conveyor bakeng sa lebokose la kabo.

Ke Hobane'ng ha U Khetha Mochini oa ho Seha Laser Tube ea tšepe?

Mehopolo ha U Reka Mochini oa ho Seha Laser Tube

#1 Ke Botenya Bofe Bo Botle boo U Lokelang ho bo Seha?

Ke habohlokoa ho khetha mochine o nepahetseng oa laser matla a tšepe laser ho itšeha hobane matla a fapaneng a laser theko e tla fapana haholo.

Khetha ho ea ka boima ba max, matsete a tla feta habonolo tekanyetso ea hau.

#3 U Hloka ho Hokahana le ERP System kapa Che?

Nahana ka boemo ba fektheri ea hau mme ho khetha selaola se loketseng sa laser e tla ba khetho e ntle.

Haeba ho se na tlhokahalo e hokahanyang litsamaiso tsa ERP le mechini e meng ea ho sila, molaoli oa China FSCUT e tla ba khetho e ntle, sebopeho se nang le botsoalle le ho sebetsa habonolo.

#5 Boleng ba Mochini le Boiphihlelo ba Feme

Ha theko ea mohloli oa laser e fokotseha haholo, ho na le lifeme tsa metjhini ea tšepe tse ntseng li eketseha tse rekisang metjhini ea ho itšeha ea tšepe.

Empa e le ho fana ka mochini o motle oa tšepe oa laser, o hloka boiphihlelo bo botle tseleng e bobebe, tsela ea motlakase, tsela ea metsi le theknoloji ea 3D ea laser.Ha e li qape hammoho feela.

Golden Laser e na le phihlelo ea lilemo tse 18 ea ho hlahisa boleng bo botle le mechine e tsitsitseng ea fiber laser tube cutting, phihlelo e ruileng ka mechine ea tšepe ea laser tube ea tšepe, sehlopha sa ka mor'a ts'ebeletso ho netefatsa hore ho na le phihlelo e ntle ea mosebedisi ea mochini oa ho itšeha oa laser tube.

#2 Na U Hloka ho Etsa Sebopeho sa Metal Tubes?

Bakeng sa tšupu ea tšepe ea sebopeho se tloaelehileng, ho bonolo ho seha, joalo ka chitja, lisekoere, le khutlonnetsepa.

Haeba ho hlokahala ho khaola liphaephe tse bōpehileng joaloka Channel Steel, ke beam, C mofuta liphaephe molemo ho hlahloba le setsebi bakeng sa habeli etsa bonnete ba hore na ka sehiloeng.

#4 Kutloisiso ea Tlhokahalo ea Kopo ea Indasteri

Mochini oa ho itšeha oa laser o nang le thuso o entsoe ho latela tlhoko e qaqileng ea bareki, mesebetsi e mengata e etselitsoe ka mor'a ho ithuta ka botebo tlhahisong ea tlhahiso ea moreki.

E kopanang le tlhoko e ka bang teng mme e nolofatsa le ho eketsa katleho ea mohala oa tlhahiso.

Bokhoni bo matla ba R&D bo bohlokoa ha u fumana baetsi ba mochini oa laser tube cuting.

#6 Ka mor'a ho Thekisoa Tšebeletso

Golden Laser e romela mochini oa ho itšeha oa laser linaheng le litoropong tse fetang 100.

U ka hlahloba boleng ba mochine oa rona sebakeng sa heno 'me u thabela ntlo le ntlo ka nako ka mor'a tšebeletso ka moemeli oa rona kapa fektheri ka ho toba.