Thumela Uphenyo ngolwazi kanye nentengo yomshini omusha we-Robot Laser Cutting Machine!

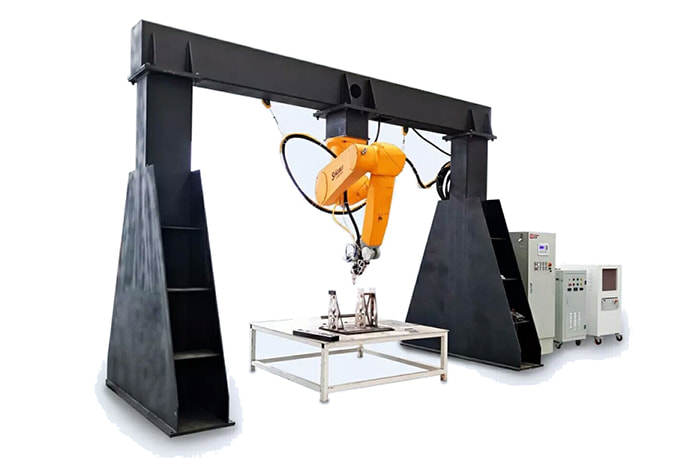

Umshini Wokusika we-laser we-3D

- Umsiki we-Fiber Laser one-Robotic Arm System.

Izithombe Ezivelele Zomshini Wokusika I-Robot 3D Laser

1. I-XR160L yenkampani yami yokubeka irobhothi lokucubungula ishidi lensimbi yezimoto eliqondene nomkhakha, imishini yezinhlelo zamarobhothi ze-Stäubli RX160L, i-IPG500W fiber laser, ikhanda le-LASERMECH laser (kufaka phakathi indlela yokunyakaza), itafula lokubeka, i-chiller, ukuphepha nezinye izingxenye eziyinhloko.

2. Ukuxhumanisa okungu-6-axis, ububanzi bomsebenzi, kuze kube yibanga elide, umthamo wokuthwala umthwalo, kungaba sesikhundleni sokusika ithrekhi ye-3D

3. Incane, ingalo encane, ngisho nasezimweni ezinzima, imikhawulo ezindaweni eziningi, isengasebenza kahle kakhulu

4. Isivinini senqubo kanye nokubekwa kwayo kungalungiswa, ukuze kufezwe ukunemba kokukhiqiza okungcono kakhulu, isivuno esikhulu, kanye nesivinini esikhulu.

5. Umsindo ophansi, isikhathi sokulungisa esijwayelekile side, isikhathi eside senkonzo

6. I-manipulator ingashintshwa nge-terminal ephathwa ngesandla

7. Ngokushintsha uhlelo kanye nezinguquko zehadiwe, ingafinyelela ukusika nge-laser, ukushisela nge-laser, ukupakisha, ukuphatha kanye neminye imisebenzi

Izici Zomshini Wokusika I-Laser Ye-3D

1. Umthombo we-laser: ukusetshenziswa kwama-laser e-IPG fiber asebenza kahle kakhulu, ukusebenza kahle okuphezulu, izindleko eziphansi zokusetshenziswa okuhlanganisiwe.

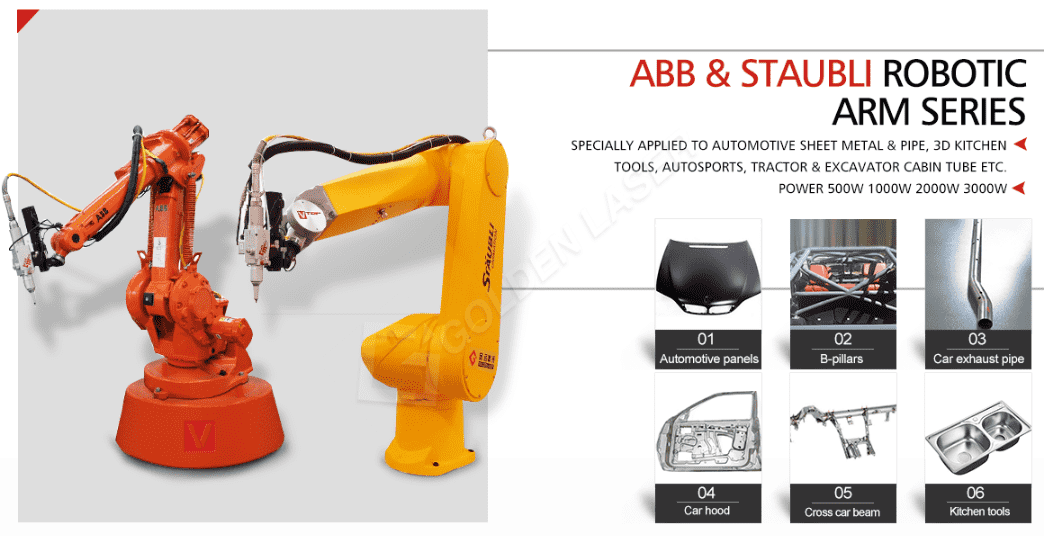

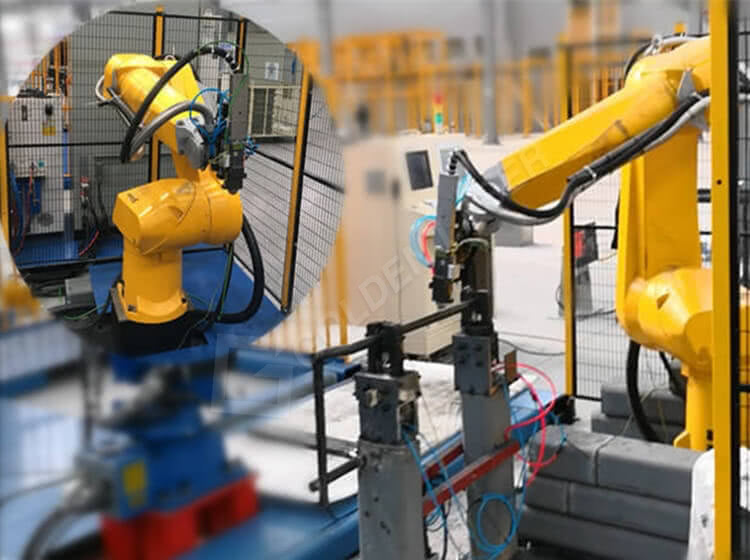

2. Ukuqaliswa kokusikwa kwe-laser kwezikhungo ezisebenzisa irobhothi laseSwitzerland i-Staubli. Irobhothi i-Staubli irobhothi elinembile kakhulu embonini yamarobhothi. Ukusetshenziswa komzimba werobhothi we-aluminium titanium alloy, ukwakheka kwe-harmonic reducer, umzimba werobhothi uma kuqhathaniswa neminye imikhiqizo, kulula, isivinini esikhulu, ukunemba okuphezulu. Amarobhothi embonini ye-TL160L asesimweni esincane sokusikwa okuncane kanye nefomethi enkulu ukutshela ukusikwa kwe-laser uma kuqhathaniswa neminye imikhiqizo kunezinzuzo ezisobala. Ekusikweni kwe-laser okusheshayo, uhlelo lwamarobhothi e-Staubli lungafinyelela isivinini esingu-18 m / min ngaphandle kokujikijela, eminye imikhiqizo ayiqinisekisi isivinini sokusikwa kwe-laser esingu-10 m / min ukuqinisekisa imiphumela emihle yokusika. Futhi ekusikweni okuncane okujikelezayo, ungasika ububanzi obuncane kakhulu bendilinga encane engu-2mm, umphumela wokusika ubushelelezi futhi muhle, okuyinto eminye imikhiqizo yamarobhothi ezimboni engenakuyenza.

3. Irobhothi le-Staubli lingalungiswa ngokuya ngezidingo zangempela zamakhasimende isofthiwe yokuhlela engaxhunyiwe ku-inthanethi, isofthiwe ingafunda isofthiwe yokumapha enezinhlangothi ezintathu yonke indawo i-vda, i-igs, i-x_t, i-sldprt, i-prt, i-par kanye nezinye izinhlobo, ngqo kunqubo yokulandelela ithrekhi yesofthiwe, Ukufundisa, kulula futhi kuyasebenza ukufeza umkhiqizo wohlobo lomsebenzi wokuhlela.

4.Landela ikhanda lokusika nge-laser yerobhothi: ongakukhetha ngemikhiqizo ephezulu yamazwe ngamazwe yekhanda lokusika nge-laser ukuqinisekisa ukuthi umsebe we-laser uhlala usendaweni yokugxila ukuqinisekisa umphumela wokusika.

5. Uhlelo lomoya olusizayo: uhlelo luhlanganisa umoya ocindezelekile, i-nitrogen, umoya-mpilo, isakhiwo somthombo wegesi emithathu kanye nendlela yegesi yokuguqulwa kwamandla aphezulu naphansi, ikhasimende lingakhetha ngokuya ngezidingo zekhwalithi yokucubungula kanye nezindleko zegesi elisizayo.

6. Uhlelo lokuthambisa: Umshini wokusika we-laser we-3d ufakwe uhlelo lokuthambisa ngesandla, olunciphisa ukuguguleka kwezingxenye ezihambayo, ukuqinisekisa isivinini esiphezulu somshini we-laser wezinhlelo zamarobhothi wonke.

Ividiyo Yokusebenza Komshini Wokusika I-Robot Fiber Laser

Umshini Wokusika I-Robotic Arm 3D Laser Kusayithi Lamakhasimende

Isampula Yamashubhu Ensimbi Nezingxenyana Zensimbi Ze-Robotic Arm 3D Laser Cutting

Ufuna Ukwazi Ulwazi Olwengeziwe mayelana Nomsiki We-Robot Laser?

Isicelo Sezinto Ezibalulekile Nezimboni

Isebenza kuzo zonke izinhlobo zokusika kwe-laser yensimbi engalingani kanye ne-sheet metal, efanele imboni yezimoto, ukukhiqizwa kwesikhunta, izitsha zasekhishini, imikhiqizo yensimbi, njengokusika okuzenzakalelayo.

1. Ngezembozo zensimbi yezimoto kanye nezingxenye ze-chassis kanye nezinye izinhlobo ezincane zokukhiqiza, njengemakethe yokulungisa, amaloli, amabhasi, imishini yokwakha, izimoto eziguquliwe njalo njalo.

2. Ngokukhiqiza okuguquguqukayo komshini wokusika nge-laser, esikhundleni sokunyathela okuvulekile, ofanele ukukhiqizwa komuntu siqu, kodwa futhi kufinyeza umjikelezo wokuthuthukiswa komkhiqizo, impendulo esheshayo emakethe.

3. Ngohlelo lokusika lwe-laser yerobhothi, esikhundleni sokusika i-plasma ngesandla, kwenza inqubo ibe lula kakhulu, kodwa futhi ihlushwe abasebenzi be-plasma bomkhiqizi ekuphathweni kwenkinga.

4. Izindleko eziphansi zemishini iyonke, ukusetshenziswa kwezindleko eziphansi, ukusebenza kahle okuphezulu, ukungeniswa okuhlukile komshini wokusika i-laser one-axis ezinhlanu, ukonga okukhulu ezindlekweni zomsebenzi ngamunye

5. Ifanele ifektri ephethe ukusekela ukuhlinzekwa kweqembu elincane lokuqala, kanye neminye imikhiqizo ukwandisa amandla okukhiqiza ngemuva kokunyathelisa isikhunta, ukuthuthukiswa kwesikhunta ukunciphisa ubungozi bokutshalwa kwezimali

Amapharamitha Obuchwepheshe Bomshini

Amapharamitha Obuchwepheshe Ayinhloko Engalo Yamarobhothi e-ABB2400

| Inani lama-axes erobhothi | 6 | Umthwalo we-axis yesithupha | 20Kg |

| I-crane yerobhothi | 1.45m | Isikhundla esiphindaphindwayo | 0.05mm |

| Isisindo | 380Kg | I-voltage | 200-600V, 50/60Hz |

| Ukusetshenziswa kwamandla | 0.58Kw | amandla alinganisiwe | 4KVA/7.8KV |

| Amapharamitha obuchwepheshe bomshini wokusika i-gantry we-ABB 2400 Robot | |||

| Imingcele iyonke yemishini | |||

| Indawo yephansi (mxm) | cishe ama-3 * 4.2 (kufaka phakathi ama-cooler kanye nohlelo lokomisa umoya olunomfutho ophezulu) | ||

| Ukuphakama kwetafula lokusebenza | 350mm | Umsindo | <65 Db (ngaphandle kokufaka ifeni yokukhipha umoya) |

| Izidingo zokunikezwa kwamandla | I-AC220V±5% 50HZ (Simplex) | Amandla aphelele | 4.5KW (Ngaphandle komoya) |

| Izidingo zemvelo | Ibanga lokushisa: 10-35 ℃ Ibanga lomswakama: 40-85% 1000 amamitha ngaphansi kolwandle, ukusetshenziswa kwemvelo ngaphandle kokuzamazama komhlaba okuvuthayo, okuqhumayo, okunamandla kazibuthe, okunamandla | ||

| Amapharamitha ayinhloko omthombo we-laser | |||

| Uhlobo lwe-laser | I-laser yefayibha | ||

| Umsebenzi we-Laser | Okuqhubekayo / ukuguqulwa kwezwi | Amandla e-laser | 700W (inketho ye-1000w 2000w 3000w) |

| Imodi ye-Spot | Imodi eminingi | Ubude be-laser | 1070nm |

| Uhlelo olusizayo | |||

| Uhlelo lokupholisa | Iphampu yephampu ephindwe kabili enokushisa okuphindwe kabili ene-chiller yesistimu yokuhlanza (ukucushwa okuhlukile) | ||

| Uhlelo lokupholisa lomthombo we-laser | Umoya opholile ongu-350W (ukucushwa okuhlukile) | ||

| Uhlelo lwegesi olusizayo | Igesi yomthombo wegesi emithathu enengcindezi ephindwe kabili (ukucushwa okuhlukile) | ||

| Ikhanda lokusika nge-laser | Ukugxila kokulandelela okunamandla | ||

Imikhiqizo ehlobene

-

I-VR16 / VR18 / VR24

I-Fiber Laser Robot Arm 3D Cutting Tube kanye nePipe Yezingxenye Zezimoto -

RE16 / RE18 / RE26

Iseli Lomshini Wokusika I-Robot Laser -

I-RN16 / RN18 / RN26 (ABB X2400D/X2400L / Staubli XR160L)

Umshini Wokusika I-Laser Ye-Robot Ye-3D Enemisebenzi Eminingi Wokusika Ishidi Lensimbi Ne-Metal Tube