Send Enquiry for the Newest Robot Laser Cutting Machine information and Price!

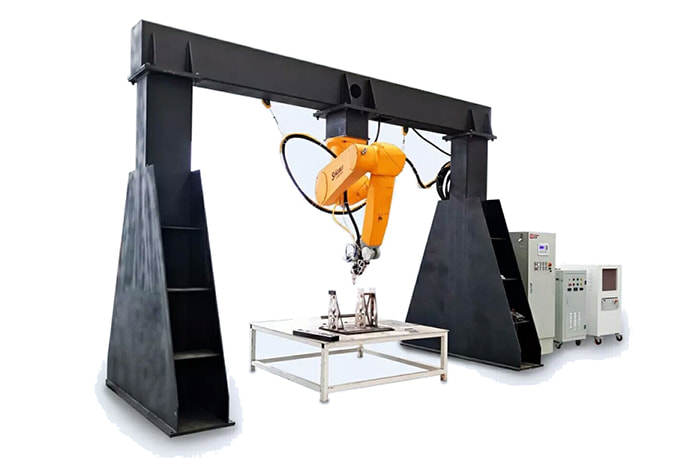

3D laser Cutting Machine

- Fiber Laser Cutter with Robotic Arm System.

Robot 3D Laser Cutting Machine Highlights

1. XR160L for my company positioning automotive sheet metal processing industry-specific robot, the equipment by the Stäubli RX160L robot systems, IPG500W fiber laser, LASERMECH laser head (including the moving mechanism), positioning table, chiller, safety and other core components.

2. 6-axis linkage, a wide range of work, up to a long distance, load-bearing capacity, can be in the work space for 3D track cutting

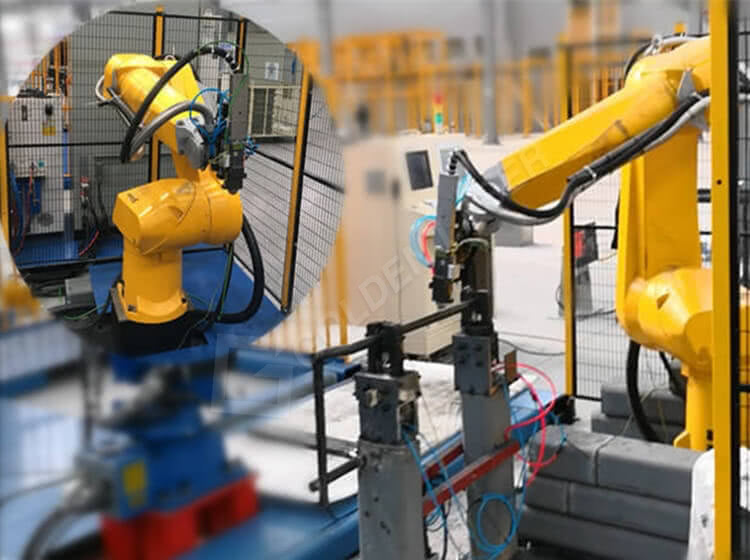

3. Compact, wrist slim, even in harsh conditions, restrictions on a lot of places, can still achieve high-performance operation

4. Process speed and positioning can be adjusted, to achieve the best manufacturing accuracy, high yield, and high speed.

5. Low noise, routine maintenance interval is long, long service life

6. The manipulator can be manipulated through a handheld terminal

7. By modifying the program and hardware changes, can achieve laser cutting, laser welding, packaging, handling and other functions

3D Laser Cutting Machine Features

1.Laser source: the use of high-performance IPG fiber lasers, high efficiency, low cost of integrated use.

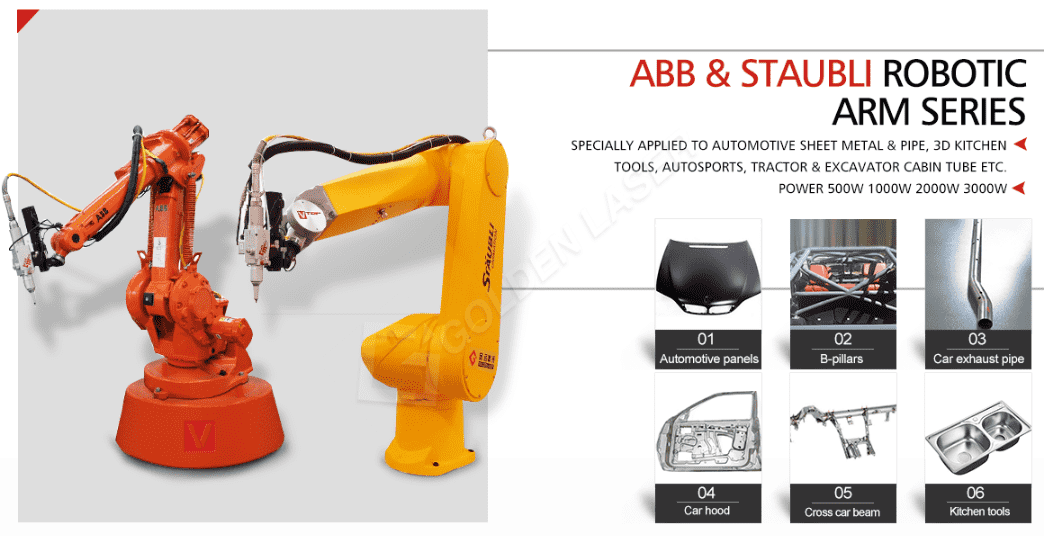

2.The implementation of the laser cutting of the implementing agencies for the Swiss Staubli robot. Staubli robot is the robot industry’s most accurate robot. The use of aluminum titanium alloy robot body, harmonic reducer design, the robot body relative to other brands, lightweight, high speed, high precision. TL160L industry robots in the small curvature of the fine cut and large format to tell the laser cut relative to other brands have obvious advantages. In high-speed laser cutting, the Staubli robots system can achieve a speed of 18 m / min without jitter, other brands rarely guarantee the laser cutting speed of 10 m / min to ensure good cutting results. Also in the small round-cut, you can cut the smallest diameter of 2mm small round, cutting effect smooth and beautiful, which other brands of industrial robots can not do.

3.Staubli robot can be configured according to the actual needs of customers off-line programming software, the software can read the three-dimensional mapping software everywhere vda, igs, x_t, sldprt, prt, par and other formats, directly in the software compiler track procedures, Teaching, simple and efficient to achieve the product of the type of programming work.

4.Follow the robot laser cutting head: optional with the international top brands of the laser cutting head to ensure that the laser beam is always in the focus position to ensure the cutting effect.

5.Auxiliary air blowing system: the system integrates high pressure air, nitrogen, oxygen three gas source structure and high and low voltage conversion gas path, the customer can choose according to the processing quality requirements and cost of auxiliary gas.

6.Lubrication system: The 3d laser cutting machine is equipped with a manual lubrication system, reduce the wear of moving parts, to ensure the high speed of the whole robot systems laser machine.

Robot Fiber Laser Cutting Machine Working Video

Robotic Arm 3D Laser Cutting Machine on Customer Site

Robotic Arm 3D Laser Cutting Metal Tubes and Metal Sheets Sample

Want Know More information about Robot Laser Cutter?

Material & Industry Application

Applicable to all kinds of uneven metal pipe and sheet metal laser cutting, suitable for the automotive industry, mold manufacturing, kitchen utensils, metal products, such as automatic cutting.

1. For automotive sheet metal coverings and chassis parts and other batches of small quantities of production, such as maintenance market, trucks, buses, construction machinery, modified cars and so on.

2. With the flexible production of laser cutting machine, instead of open stamping, suitable for personalized production, but also shorten the product development cycle, rapid response to the market.

3. With the robot laser cutting system, instead of hand-held plasma cutting, greatly simplifies the process, but also has been plagued by the manufacturer’s plasma workers in the management of the problem.

4. The total low cost of equipment, the use of low cost, high efficiency, alternative imports of five-axis laser cutting machine, significant savings in the cost of each workpiece

5. Suitable for the host factory supporting the early small batch supply, and other products to increase production capacity after the mold stamping, mold development to reduce the risk of investment

Machine Technical Parameters

ABB2400 Robotic Arm Main Technical Parameters

| The number of axes of the robot | 6 | Sixth axis load | 20Kg |

| Robotic crane | 1.45m | Repeated position | 0.05mm |

| Weight | 380Kg | Voltage | 200-600V,50/60Hz |

| Power consumption | 0.58Kw | rated power | 4KVA/7.8KV |

| ABB 2400 Robot gantry cutting machine technical parameters | |||

| The overall parameters of the equipment | |||

| Floor space(mxm) | about 3 * 4.2 (including chillers and high pressure air drying system) | ||

| Worktable height | 350mm | Noise | <65 Db(not including exhaust fan) |

| Power supply requirements | AC220V±5% 50HZ (Simplex) | Total power | 4.5KW (Without ventilation) |

| Environmental requirements | Temperature range: 10-35 ℃ Humidity range: 40-85% 1000 meters below sea level, the use of the environment without flammable, explosive, strong magnetic, strong earthquake | ||

| The main parameters of the laser source | |||

| Laser type | Fiber laser | ||

| Lasers work | Continuous / modulation | Laser power | 700W (1000w 2000w 3000w option) |

| Spot mode | Multi-mode | Laser wavelength | 1070nm |

| Auxiliary system | |||

| Cooling system | Dual-temperature dual-pump pump with purification system chiller (unique configuration) | ||

| Laser source cooling system | 350W horizontal air conditioning (unique configuration) | ||

| Auxiliary gas system | Three gas source dual-pressure gas (unique configuration) | ||

| Laser cutting head | Capacitive follow-up focus | ||

Related products

-

VR16 / VR18 / VR24

Fiber Laser Robot Arm 3D Cutting Tube and Pipe For Auto Parts -

RN16 / RN18 / RN26 (ABB X2400D/X2400L / Staubli XR160L)

Multifunction 3D Robot Laser Cutting Machine For Metal Sheet And Metal Tube Cut -

RE16 / RE18 / RE26

Robot Laser Cutting Machine Cell