-

The Way of Cypcut Fiber Laser Cutting Machine connect to MES system for digital connect to CRM and ERP In the industry 4.0

We know the production efficiency is the key point in metal processing manufacture, how to increase the production efficiency by the digital technology? With many years development, the fiber laser cutting machine from hundreds of power up to tens of thousand of laser power, it already increase the times of metal sheet and tube cutting speed. Many of...Read moreJun-13-2024

-

How to Avoid Metal Laser Cutting Occurs Over Burning?

When we cut metal materials by fiber laser cutting machine occurs over burning. What should I do? We know Laser cutting focuses laser beam on the material surface to melt it, and at the same time, compressed gas collimated with the laser beam is used to blow away the molten material, while the laser beam is moving with the material relative to a certain trajectory to form a certain shape of cutting slot. Below process is continuously repeat...Read moreOct-17-2023

-

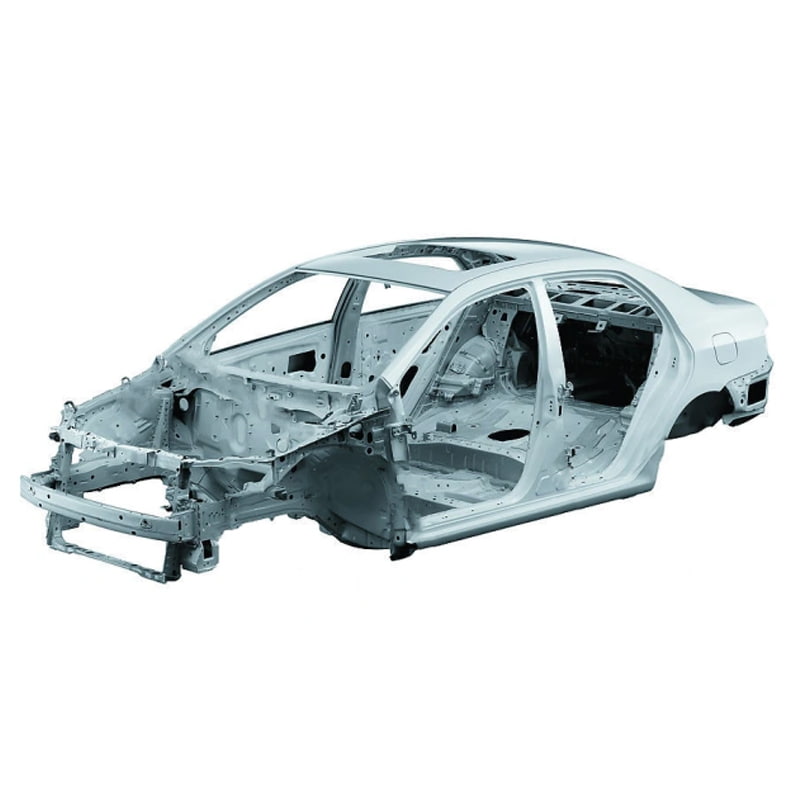

The Application and Development of Laser Technology in the Automotive Industry

In today's laser processing industry, laser cutting accounts for at least 70% of the application share in the laser processing industry. Laser cutting is one of the advanced cutting processes. It has many advantages. It can carry out precise manufacturing, flexible cutting, special-shaped processing, etc., and can realize one-time cutting, high speed, and high efficiency. It sol...Read moreJul-04-2023

-

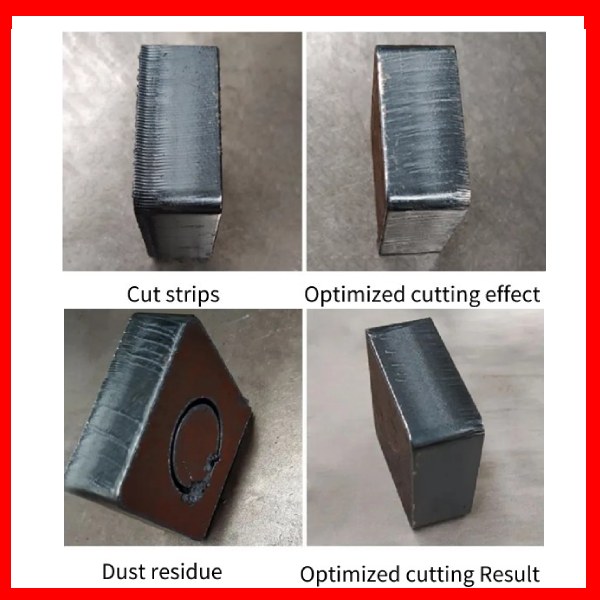

Troubleshooting High Power Laser Cutting: Common Problems and Effective Solutions

With inimitable advantages similar to thick metal sheet ability, presto cutting speed, and capability to cut thicker plates, high-power fiber laser cutting has been extensively honored by the request. still, because high-power fiber laser technology is still in the original stage of popularization, some operators aren't veritably professed in high-power fiber laser chops. The high-power fiber laser machine technician ...Read moreFeb-25-2023

-

4 Tips on Stainless Steel Laser Cutting by 10000W+ Fiber Laser

According to Technavio, the global fiber laser market is expected to grow by US$9.92 billion in 2021-2025, with an annual growth rate of about 12% during the forecast period. The driving factors include the increasing market demand for high-power fiber lasers, and "10,000 watts" has become one of the hot spots in the laser industry in recent years. In line with market development and user needs, Golden Laser has suc...Read moreApr-27-2022

-

High Power Laser Cutting VS Plasma Cutting in 2022

In 2022, high power laser cutting machine has opened the era of plasma cutting replacement With the popularity of high-power fiber lasers, fiber laser cutting machine continues to break through the thickness limit, is increasing the share of plasma cutting machine in the thick metal plate processing market. Before 2015, the production and sales of high-power lasers in China is low, laser cutting in the application of thick metal has l...Read moreJan-05-2022