In today's laser processing industry, laser cutting accounts for at least 70% of the application share in the laser processing industry. Laser cutting is one of the advanced cutting processes. It has many advantages. It can carry out precise manufacturing, flexible cutting, special-shaped processing, etc., and can realize one-time cutting, high speed, and high efficiency. It solves the problem of industrial production. Many difficult problems cannot be solved by conventional methods in the process.

If it is divided by the material of the automobile industry. It can be divided into two types of laser cutting methods: flexible non-metal and metal.

A. CO2 laser is mainly used to cut flexible materials

1. Automobile airbag

Laser cutting can efficiently and accurately cut airbags, ensure the seamless connection of airbags, ensure product quality to the greatest extent, and allow car owners to use it with confidence.

2. Automotive interior

Laser-cut additional seat cushions, seat covers, carpets, bulkhead pads, brake covers, gear covers, and more. Car interior products can make your car more comfortable and easier to disassemble, wash, and clean.

The laser cutting machine can flexibly and quickly cut drawings according to the internal dimensions of different models, thereby doubling the product processing efficiency.

B. Fiber laser is mainly used for processing metal materials.

Let's talk about the processing method of fiber laser cutting in the automobile frame manufacturing industry

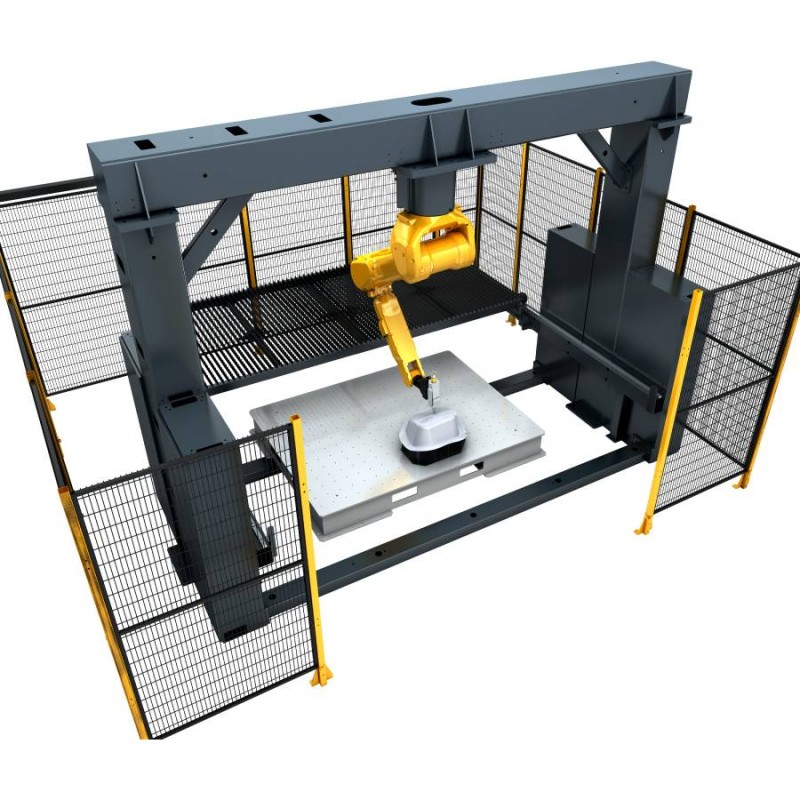

The cutting dimension can be divided into plane cutting and three-dimensional cutting. For high-strength steel structural parts, laser cutting is undoubtedly the best cutting method, but for complex contours or complex surfaces, no matter from a technical or economic point of view, laser cutting with a 3D robot arm is a very effective processing method.

Cars continue to go further and further down the road of lightweight, and the application of thermoformed high-strength steel is becoming more and more extensive. Compared with ordinary steel, it is lighter and thinner, but its strength is higher. It is mainly used in various key parts of the car body. , such as the anti-collision beam of the car door, front and rear bumpers, A-pillar, B-pillar, etc., are key factors to ensure vehicle safety. The hot-formed high-strength steel is formed by hot stamping, and the strength after the treatment is increased from 400-450MPa to 1300-1600MPa, which is 3-4 times that of ordinary steel.

In the traditional trial production stage, work such as edge trimming and hole cutting of stamping parts can only be done by hand. Generally, at least two to three processes are required, and molds must be continuously developed. The accuracy of cutting parts cannot be guaranteed, the investment is large and the loss is fast. But now the development cycle of models is getting shorter and shorter, and the quality requirements are getting higher and higher, and it is difficult to balance the two.

The three-dimensional manipulator laser cutting machine can complete the trimming and punching processes after the blanking, calendering, and shaping of the cover are completed.

The heat-affected zone of fiber laser cutting is small, the incision is smooth and burr-free, and it can be used directly without subsequent processing of the incision. In this way, complete automotive panels can be produced before the complete set of molds is completed, and the development cycle of new automotive products can be accelerated.

3D robot Laser Cutting Machine Application Industry.

Laser cutting has quickly occupied the market with its unparalleled advantages such as precision, speed, high efficiency, high performance, low price, and low energy consumption, and has become indispensable processing equipment in the automotive industry, and is widely used in large-scale parts processing, automotive, aerospace, The processing of small batches and prototypes in industries such as rolling stock, construction machinery, agricultural machinery, turbine components, and white goods, and batch processing of metal hot-formed parts.

Laser Cutting Video In Automobile Industry Line

Related Fiber Laser Cutter

Sheet Metal Laser Cutting Machine

Over 10KW Fiber Laser Cutting Machine Easy Cut Thin and Thick Metal Sheet into any complicated Design.

Tube Laser Cutting Machine

With the PA CNC controller and Lantek Nesting Software, it is easy to cut various shape pipes. 3D Cutting Head Easy to cut 45-degree Pipe

Robot Laser Cutting Machine

3D Robot Laser Cutting With Up or Down Mounting Method For Different size automobile frame Cutting.