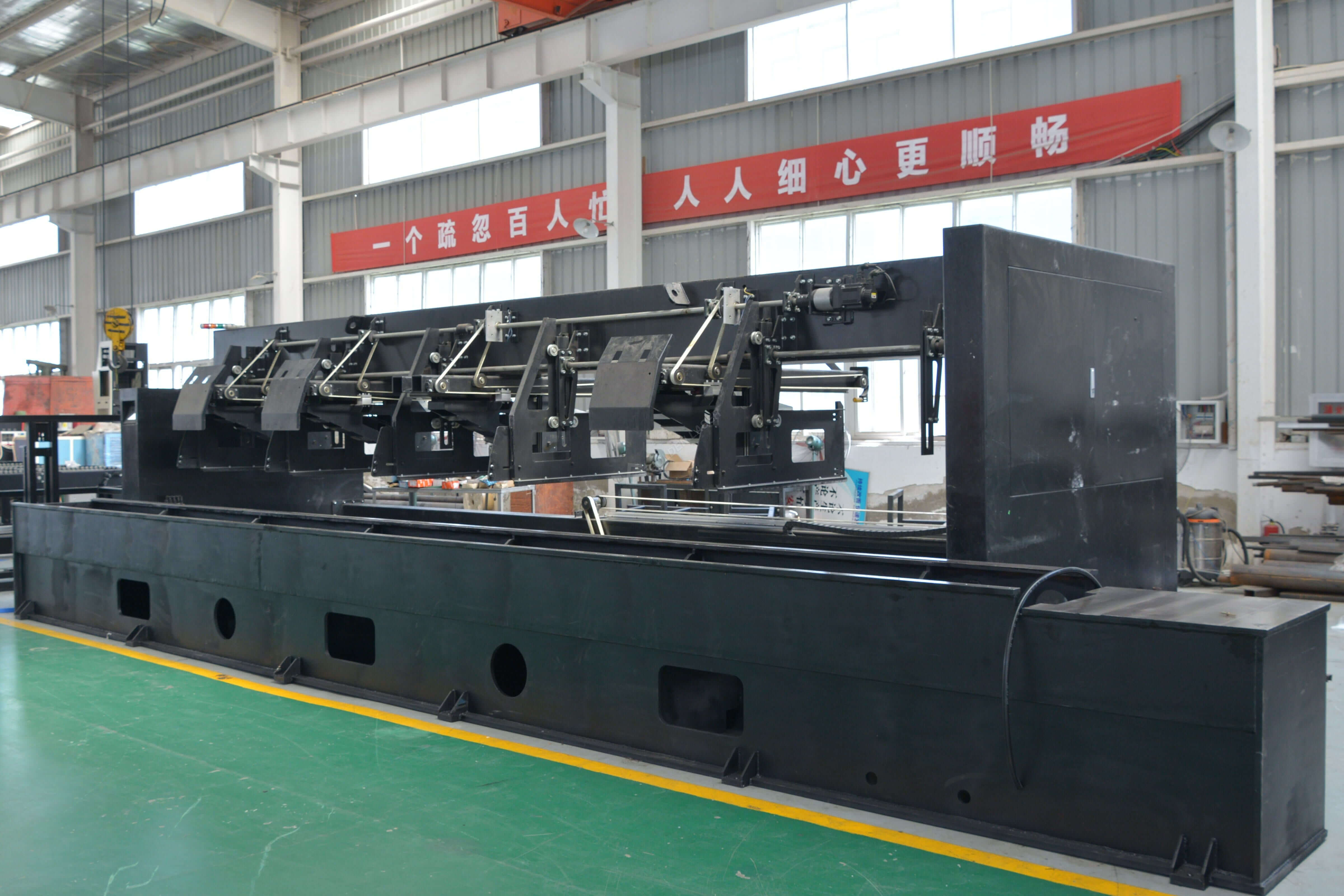

Umatshini wokusika i-laser yeGolden Laser pipe uthotho lwe-P lusebenzisa eyona resonator ye-laser ephucukileyo ye-fiber laser i-Nlight okanye i-IPG evela e-USA, kunye nentloko yokusika i-laser ye-fiber evela eSwitzerland's Raytools, edibanisa ibhedi yomatshini we-CNC oyilwe ngokwakho kunye nomzimba we-welding onamandla aphezulu, lo matshini usebenza kakuhle.

Emva kokufakelwa kobushushu obuphezulu kunye nomatshini wokugawula we-CNC omkhulu, unokuqina okuhle kunye nozinzo. Ngokusebenzisa iindawo ezingasetyenziswayo ezichanekileyo eziphezulu ezingenisiweyo, ezifana ne-linear guide drive, i-servo motor enesantya esiphezulu, umqadi we-aluminium, inkqubo yonyango lobushushu oluphambili, amandla aphezulu, ubunzima obulula, ukuqina okuhle, umatshini uthandwa kakhulu kwimarike yasekhaya okanye ebanzi.

1.Ubude bombhobho wenkunkuma obuncinci bungaphakathi kwe-20mm, nto leyo etyhala imida.

2. Umatshini wokusika ipayipi ye-CNC kulula ukuwufunda nokuyiqhuba, umqhubi omnye unokulawula oomatshini ababini ngexesha elinye, kwaye abafazi nabo banokuyisebenzisa. Ngolawulo olunamandla, umatshini kulula ukuwuqalisa nokuyimisa; emva kokuba inkqubo yokusika ipayipi igqityiwe, umatshini uya kuma ngokuzenzekelayo, kwaye iipayipi ezigqityiweyo zikwibhokisi yokuqokelela.

3. Ukuguga kabini kokungcangcazela kunye nokuqhoboshela kuqinisekisa umatshini ngozinzo oluhle kunye nokuchasana nokushukuma, ngoko ke ukuchaneka komatshini kuya kuhlala iminyaka eli-15.

4. Ufakelo lwesikhokelo lusebenzisa izixhobo eziphezulu ezifana nezixhobo zokulinganisa kunye nee-laser interferometers ukuqinisekisa ukuba ubungakanani bofakelo buyi-55mm.

5. Inkqubo yokondla ngemibhobho ezenzekelayo yenza ukutya nokusika okuninzi ngemibhobho ngokuzenzekelayo, kwaye ukondla kuchanekile kwaye kuyakhawuleza. Isebenza ngokuzenzekelayo kakhulu, ayinazimpazamo kwaye ayongi abasebenzi. Inkqubo yokondla ngokuzenzekelayo ixhasa imibhobho ye-bunch ye-800 * 800mm, ubunzima obukhulu bokulayisha yi-25kg ngemitha.

6. I-guid rail ixhotyiswe ngenkqubo yokuthambisa ezenzekelayo, ukuze iqinisekise ukusebenza kakuhle ixesha elide ngaphandle kokuma.

7. Ingayitshintsha ngokuzenzekelayo intambo yomgca kwaye iphephe ukungqubana ngokwemingxunya eyahlukeneyo, kwaye ilinganise ngokuzenzekelayo i-vector ukuthintela ukungqubana, le misebenzi isebenza ngokukodwa kwiityhubhu ezinemilo ekhethekileyo. I-algorithm yokulinganisa iya kwahluka ngokuxhomekeke kwiityhubhu ezahlukeneyo.

8. Ingalinganisa iindawo ukuze zidwebe uyilo ngokweebhetshi ngefomathi ye-EXCEL, nto leyo elula kwaye igcina ixesha elininzi lokuzoba.

9. Siza kutshintshiselana ngezinye iindawo, izinto ezibalulekileyo okanye ubuchwepheshe obuphambili ukuze sifezekise ukuphuculwa komatshini wokusika i-laser yombhobho, kwaye senze amandla okuvelisa, ukusebenza, ukusebenza kakuhle njl.njl. komatshini wokuqala okanye umgca wokuvelisa uhlaziywe. Ngaloo ndlela olu phuculo lwandisa ubomi bomsiki we-laser yombhobho, lugcina izinto eziluhlaza kunye nomsebenzi, lunciphisa iindleko.

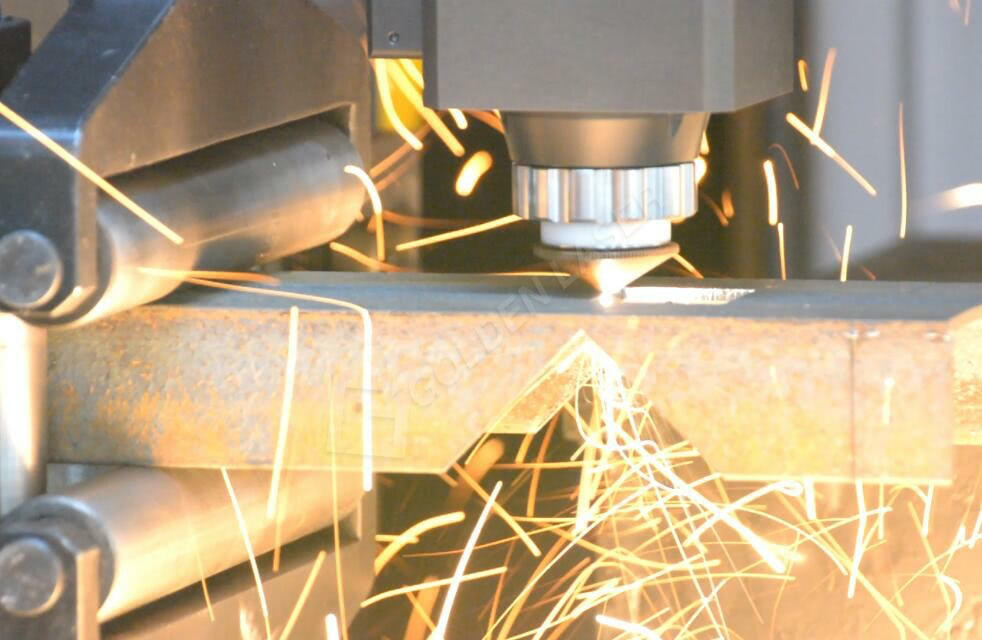

10. Ukuqina kokusika kakuhle kunye nesantya sokusika, isantya sokusika sifikelela kwiimitha ezingama-90 ngomzuzu, kwaye i-engile yokusika iyatshintsha. Ngokwenza izinto ngokuzenzekelayo okuphezulu, konga ixesha elininzi lomsebenzi. Izixhobo kulula ukuzigcina, nto leyo eyandisa ubomi benkonzo yazo.

11. Ekubeni uxhaso olunezangqa ezahlukeneyo lunamandla amakhulu okubamba, ngoko ke umbhobho awuyi kujika ukuze ubangele ukuchaneka okungachanekanga. Kwaye ireyile yesikhokelo isebenzisa isixhobo sokuthambisa esizenzekelayo ukuze kungabikho tshintsho lokuma komatshini.

12. Ipleyiti yobuso bokugqibela kunye nomjelo wesilayidi wangaphakathi zonke azinalo uthuli, kwaye ichuck yangasemva inesixhobo sokutsala uthuli, zonke ezi zinto zinokwenza umatshini usebenze kakuhle.

13. Lo matshini ufanelekile ukusika izinto zesinyithi ezikhanyayo kakhulu ezifana nobhedu, i-aluminium, ipayipi ye-galvanized kunye nezinye. Kwaye uxhasa uyilo lwepayipi olujikelezileyo, olusikwere, oluyingxande, oluyi-elliptical, oluyinxantathu, oluyi-pentagonal, oluthe tyaba, oluyi-angle, oluyi-channel, olungaqhelekanga kunye nezinye iintlobo zoyilo lwepayipi, nto leyo egcina ixesha lophuhliso lwemveliso entsha.

14. Ezi zixhobo ziphuhliswe ngokusebenzisa usetyenziso olubanzi kushishino kunye namava amaninzi okufakela. Nokuba kukulayisha okanye ukusika izinto, ixabiso lokulinganisa elichanekileyo lombhobho ngamnye lisetyenziselwa ukubala ngokuzenzekelayo ukusetyenziswa kwezixhobo ezifanelekileyo kunye nokugcina izinto kangangoko. Inkunkuma iyancipha ngokwendalo.

15. Akukho luthuli kwaye akukho ngxolo, yenzelwe ngokukodwa ishishini lokukhusela okusingqongileyo.

16. Inomsebenzi wokukhangela umphetho ozenzekelayo, ukuba umbhobho uthambekele ecaleni, intloko yokusika inokuyichonga ngokuzenzekelayo ize izalisekise ithambekele ecaleni.

17. Iipayipi ezikwinqanaba lokunyamezela elimiselweyo zinokubonwa. Ukuba ubude bepayipi abufanelekanga, buza kulumkisa.

18. Ingawenza umsebenzi wokusika ngokuchanekileyo wonke uyilo oluntsonkothileyo olungenakwenziwa zii-aw blade molds ezifana nokusika imingxunya, ukunqumla, ukusika iipateni ezinzima, imigca edibanisayo njl.njl.

19. Kwipayipi etyebileyo inomsebenzi wokulungisa ukugxila ngokuzenzekelayo, onokunyusa izinga lokuvelisa ngaphandle kokuqhuma kwemingxunya; ukuphucula ukusebenza kakuhle kokusika nokunciphisa ixesha lokusika; ukutshintshiselana kwepayipi ebhityileyo kunye nepayipi etyebileyo kunokufumana ngokuzenzekelayo iiparameter ezifanelekileyo kwilayibrari yenkqubo.

20. Kwi-P series pipe laser cutting machine, sineemodeli ezintathu ozikhethileyo ze-P2060, P3080 kunye ne-P30120, ngoko ke inokucubungula ubude bepayipi obuyi-6000m, 8000mm, 12000mm.

21. Ububanzi obungaphandle bombhobho bufanele bube ngaphakathi kwe-320mm okanye i-diagonal ibe ngaphakathi kwe-320mm.

22. Umatshini unokusika i-arc, i-groove, i-oblique.

23. I-chuck ilungisa ngokuzenzekelayo amandla okubamba ngokwendlela uhlobo lwetyhubhu, ububanzi kunye nobukhulu bodonga njl.njl. Ityhubhu encinci ayizukujika kwaye ityhubhu enkulu ibotshelelwe ngokuqinileyo.

24. Isoftware yokulawula umatshini inamandla okufunda kunye nokwakha iindlwane ngobuchule; inokucubungula uyilo lwe-3D ngokwenkqubo yeGolden Laser CAD-CAM.

25. Izixhobo ezisemgangathweni ophezulu ezingenisiweyo kwamanye amazwe, izixhobo zomoya ezisetyenziswa kumatshini zamkela iimpawu ezivela kwamanye amazwe, ngaloo ndlela zinokuqinisekisa ukuba inkqubo yomatshini izinzile kwaye iyahlangabezana nemigangatho yokuthumela ngaphandle.

26. Izinto ezikumgangatho ophezulu ezingenisiweyo, i-pneumatic compone

Iimveliso ezisetyenziswa kumatshini zamkela iimpawu ezivela kwamanye amazwe, ngaloo ndlela zinokuqinisekisa ukuba inkqubo yomatshini izinzile kwaye iyahlangabezana nemigangatho yokuthumela ngaphandle.

27. Ukuchaneka kokusika yi ± 0.03mm.

28. Lo matshini unako ukusika amabhakethi kunye nokulungisa umngxuma.

29. Umgangatho wokusika umatshini uphezulu. Umbhobho awuyi kuguqulwa bubushushu, kwaye udonga lwangaphakathi luthambile emva kokusikwa, umphezulu uthambile kwaye akukho mfuneko yokusikwa kwesibini, akukho burr ngaphandle kokuncitshiswa kwaye kulula ukuwelda.

30. Umatshini ungasika i-engile ye-30°, 45° okanye 90° ngokwendlela umthengi ayisebenzisa ngayo, ii-engile ezimbini ze-45° zinganqunyulwa zibe yi-engile ye-90° ngokugqibeleleyo.