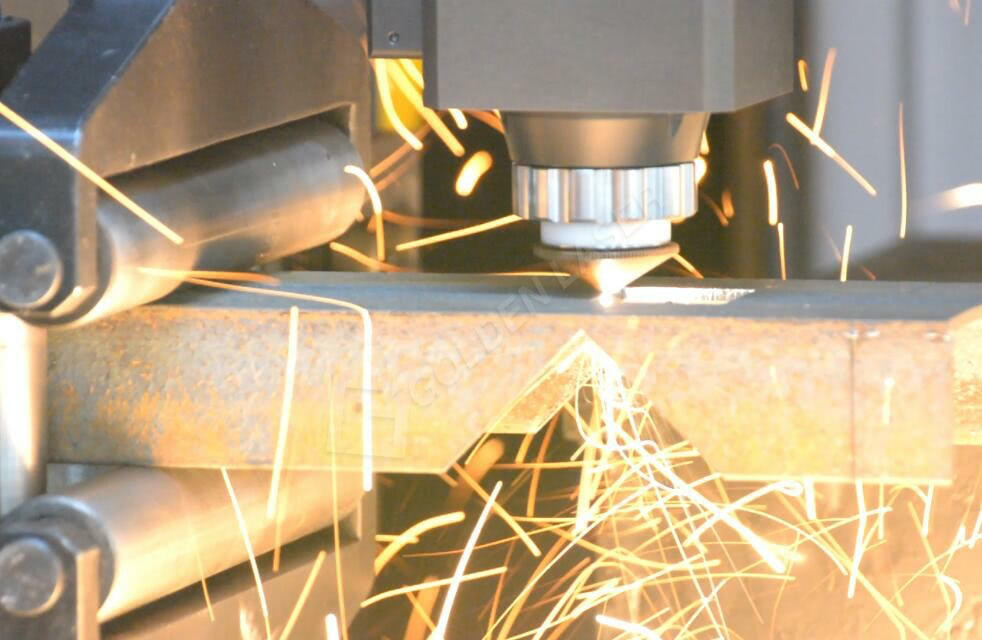

Umshini wokusika ipayipi le-laser yeGolden Laser uchungechunge lwe-P usebenzisa i-resonator ye-laser ye-fiber eyinkimbinkimbi kakhulu i-Nlight noma i-IPG evela e-USA, kanye nekhanda lokusika i-laser ye-fiber elingenisiwe elivela eSwitzerland's Raytools, elihlanganisa umbhede womshini we-CNC oklanyelwe wena kanye nomzimba wokushisela onamandla aphezulu, umshini usebenza kahle.

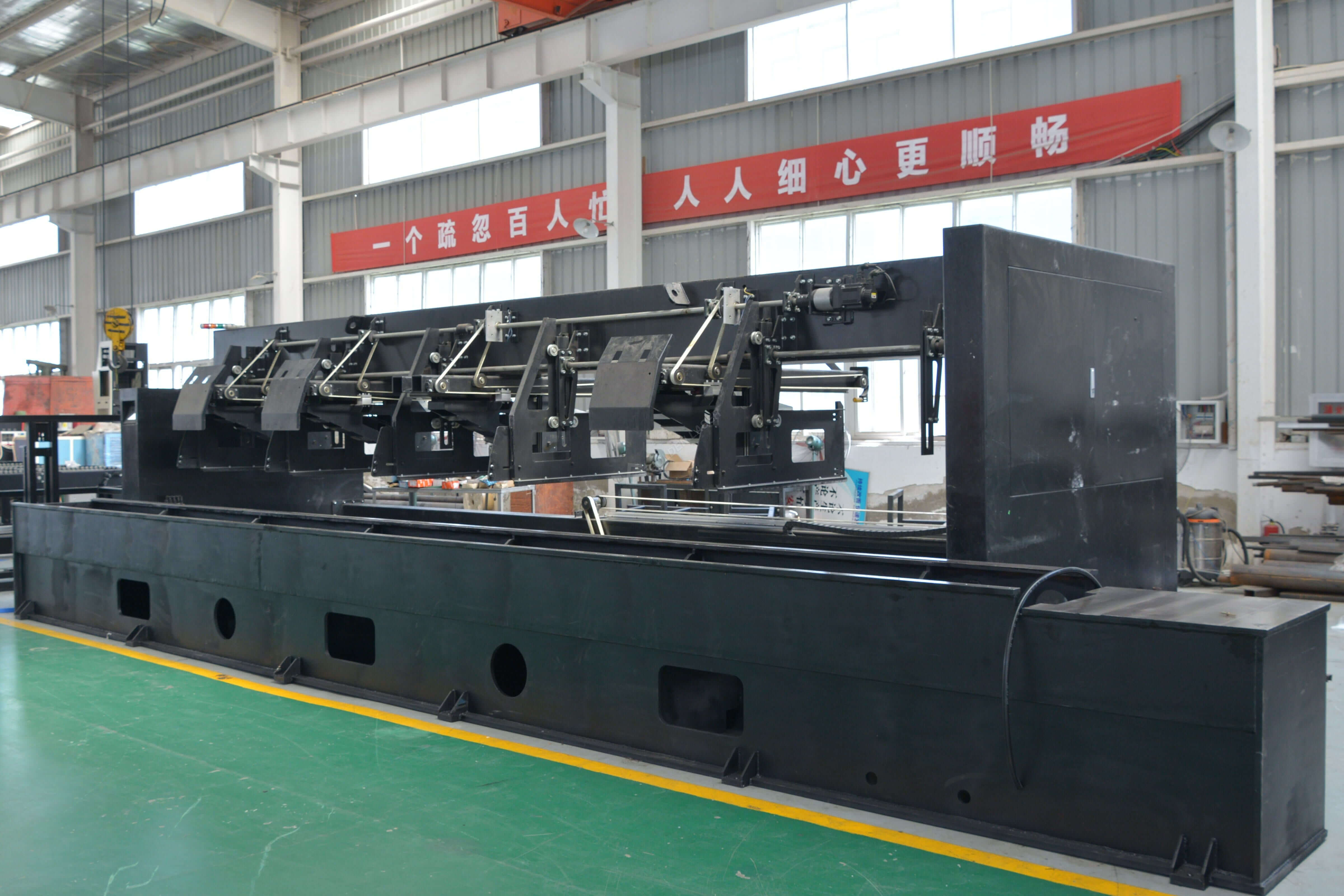

Ngemva kokufakelwa kwezinga lokushisa eliphezulu kanye nomshini wokugaya ngokunemba ngomshini omkhulu wokugaya we-CNC, unokuqina okuhle kanye nokuqina. Ngokusebenzisa izingxenye ezisele ezingenisiwe ngokunemba okuphezulu, njenge-linear guide drive, i-servo motor enesivinini esikhulu, i-aluminium beam, inqubo yokwelapha ukushisa ethuthukisiwe, amandla aphezulu, isisindo esincane, ukuqina okuhle, umshini ubelokhu uthandwa kakhulu emakethe noma ebanzi.

1.Ubude bepayipi likadoti obuncane bungaphakathi kwama-20mm, okuphusha imingcele.

2. Umshini wokusika ipayipi le-CNC laser kulula ukuwufunda nokuwusebenzisa, umqhubi oyedwa angalawula imishini emibili ngesikhathi esisodwa, kanti nabesifazane bangawusebenzisa. Ngomshini wokulawula onamandla, umshini kulula ukuwuqala nokuwumisa; ngemva kokuba inqubo yokusika ipayipi isiqediwe, umshini uzoma ngokuzenzakalelayo, futhi amapayipi aqediwe asebhokisini lokuqoqa.

3. Ukuguga nokudlidliza kabili kuqinisekisa ukuthi umshini uzinzile futhi ulwa nokunyakazisa, ngakho-ke ukunemba komshini kuzohlala iminyaka eyi-15.

4. Ukufakwa kwesiqondiso konke kusebenzisa imishini esezingeni eliphezulu njengezinsimbi zokulinganisa kanye nama-interferometer e-laser ukuqinisekisa indiza yedatha yokufaka yobukhulu obungu-55mm.

5. Uhlelo lokuphakelwa kwamapayipi oluzenzakalelayo lwenza inani elikhulu lokuphakelwa kwamapayipi nokusika ngokuzenzakalelayo, futhi ukuphakelwa kunembile futhi kuyashesha. Kusebenza ngokuzenzakalelayo kakhulu, akuthambekeli kakhulu emaphutheni futhi konga abasebenzi. Uhlelo lokuphakelwa oluzenzakalelayo lusekela amapayipi amakhulu angu-800 * 800mm, isisindo esiphezulu sokulayisha singama-25kg ngemitha.

6. I-guid rail ifakwe uhlelo lokuthambisa oluzenzakalelayo, ngakho-ke ingaqinisekisa ukusebenza kahle kwesikhathi eside ngaphandle kokuma.

7. Ingashintsha ngokuzenzakalelayo umugqa wokuqondisa futhi igweme ukungqubuzana ngokwezimbobo ezahlukene, futhi ilinganise ngokuzenzakalelayo i-vector ukuze ivimbele ukungqubuzana, le misebenzi isebenza kahle kakhulu kumashubhu anomumo okhethekile. I-algorithm yokulinganisa izohluka futhi kuye ngamashubhu ahlukene.

8. Ingahlukanisa izingxenye zibe yipharamitha yokudweba umklamo ngefomethi ye-EXCEL, okuyinto elula futhi esindisa isikhathi esiningi sokudweba.

9. Sizoshintshana ngezingxenye ezithile, izingxenye ezibalulekile noma ubuchwepheshe obubalulekile ukuze sifinyelele ukuthuthukiswa komshini wokusika ipayipi nge-laser, futhi senze amandla okukhiqiza, ukusebenza kahle, njll. komshini wokuqala noma umugqa wokukhiqiza kubuyekezwe. Ngakho-ke lokhu kuthuthukiswa kwandisa impilo yesikhathi eside yomsiki wepayipi nge-laser, konga izinto zokusetshenziswa kanye nomsebenzi, kunciphisa izindleko.

10. Ukuqina okuhle kokusika kanye nesivinini sokusika, isivinini sokusika sifinyelela kumamitha angu-90 ngomzuzu, futhi i-engeli yokusika iyashintsha. Ngokuzenzakalelayo okuphezulu, konga isikhathi esiningi somsebenzi. Imishini kulula ukuyinakekela okwandisa impilo yayo yesevisi.

11. Njengoba ukusekela okuhlukahlukene kobubanzi kunamandla amakhulu okubopha, ngakho-ke ipayipi ngeke lijike ukuze libangele ukunemba okunganembile. Futhi isitimela sokuqondisa sisebenzisa idivayisi yokuthambisa ezenzakalelayo ukuze kungabikho ushintsho lokuma komshini.

12. Ipuleti lobuso lokugcina kanye nomsele oshelelayo wangaphakathi konke akuvimbeli uthuli, futhi i-chuck yangemuva inedivayisi yokukhipha uthuli, konke lokhu kungenza umshini usebenze kahle.

13. Lo mshini ufanelekela ukusika izinto zensimbi ezibonisa ukukhanya okuphezulu njengethusi, i-aluminium, ipayipi elihlanganisiwe nezinye. Futhi usekela izinhlobo zomklamo wamapayipi eziyindilinga, eziyisikwele, eziyisikwele, ezi-elliptical, ezinxantathu, ezi-pentagonal, ezisicaba, ezi-angle, ezi-channel, ezingavamile kanye nezinye izinhlobo zomklamo wamapayipi, okusindisa isikhathi sokuthuthukiswa komkhiqizo omusha.

14. Imishini yakhiwe ngokusebenzisa izinhlelo zokusebenza eziningi embonini kanye nokuhlangenwe nakho okuningi kokufakwa. Kungakhathaliseki ukuthi ukulayisha noma ukusika izinto, inani elinembile lokulinganisa lepayipi ngalinye lisetshenziselwa ukubala ngokuzenzakalelayo ukusetshenziswa kwezinto ezifanele futhi kulondolozwe izinto ngezinga eliphezulu. Imfucuza iyancipha ngokwemvelo.

15. Akukho uthuli futhi akukho msindo, yenzelwe ngokukhethekile imboni yokuvikela imvelo.

16. Inomsebenzi wokusesha onqenqemeni oluzenzakalelayo, uma ipayipi lichemile, ikhanda lokusika lingayibona futhi liyigcwalise ngokuzenzakalelayo ichemile.

17. Amapayipi angaphakathi kwebanga lokubekezelela elibekiwe angatholakala. Uma ubude bepayipi bungafaneleki, buzokwethusa.

18. Ingakwazi ukusika ngokunembile zonke izinhlobo zomklamo oyinkimbinkimbi ongenakufezwa yizikhunta ze-aw blade ezifana nokusika imigodi, ukusika, ukusika iphethini enzima, imigqa ehlanganayo njll.

19. Kwipayipi elijiyile linomsebenzi wokulungisa ukugxila okuzenzakalelayo, ongakhuphula izinga lokukhiqiza ngaphandle kokuqhuma kwemigodi; ukuthuthukisa ukusebenza kahle kokusika nokunciphisa isikhathi sokusika; ukushintshaniswa kwepayipi elijiyile nepayipi elijiyile kungathola ngokuzenzakalelayo amapharamitha ahambisanayo kulabhulali yenqubo.

20. Ngomshini wokusika ipayipi we-laser wochungechunge lwe-P sinamamodeli amathathu ongakhetha kuwo i-P2060, i-P3080 kanye ne-P30120, ngakho-ke ingacubungula ubude bepayipi obungu-6000m, 8000mm, 12000mm.

21. Ububanzi bangaphandle bepayipi kufanele bube ngaphakathi kuka-320mm noma ububanzi obuphakathi kuka-320mm.

22. Umshini ungasika i-arc, i-groove, i-oblique.

23. I-chuck ilungisa ngokuzenzakalelayo amandla okubopha ngokohlobo lwethubhu, ububanzi kanye nobukhulu bodonga njll. Ithubhu elincane ngeke lishintshe futhi ithubhu elikhulu liboshwe ngokuqinile.

24. Isofthiwe yokulawula umshini inekhono lokufunda eliqinile kanye nokwakha izidleke ngokuhlakanipha; ingacubungula umklamo we-3D ngokuya ngohlelo lwe-Golden Laser CAD-CAM.

25. Izingxenye zekhwalithi ephezulu ezingenisiwe, izingxenye zomoya ezisetshenziswa emshinini zamukela izinhlobo ezingenisiwe, ngaleyo ndlela zingaqinisekisa ukuthi uhlelo lomshini luzinzile futhi luhlangabezana nezindinganiso zokuthumela kwamanye amazwe.

26. Izingxenye zekhwalithi ephezulu ezingenisiwe, i-pneumatic compone

Ama-nt asetshenziswa emshinini amukela izinhlobo ezingenisiwe, ngakho-ke angaqinisekisa ukuthi uhlelo lomshini luzinzile futhi luhlangabezana nezindinganiso zokuthumela kwamanye amazwe.

27. Ukunemba kokusika kungu-± 0.03mm.

28. Umshini uyakwazi ukusika amabhakede nokucubungula umsele.

29. Ikhwalithi yokusika komshini iphezulu. Ipayipi ngeke liguqulwe ukushisa, futhi udonga lwangaphakathi lubushelelezi ngemva kokusika, indawo ibushelelezi futhi asikho isidingo sokugaya okwesibili, i-zero burr ngaphandle kokuncipha futhi ilungele ukushiselwa.

30. Umshini ungasika i-engeli engu-30°, 45° noma 90° ngokwendlela ikhasimende elisebenzisa ngayo, ama-engeli amabili angu-45° angahlukaniswa abe yi-engeli engu-90° ngokuphelele.