Ishubhu Eliyindilinga | Isixazululo Sokusika Nge-Laser - Ubuchwepheshe Obugcwele Bokucubungula Insimbi Yeshubhu Eliyindilinga

Iyini i-Oval Tube kanye nohlobo lwama-Oval Tubes?

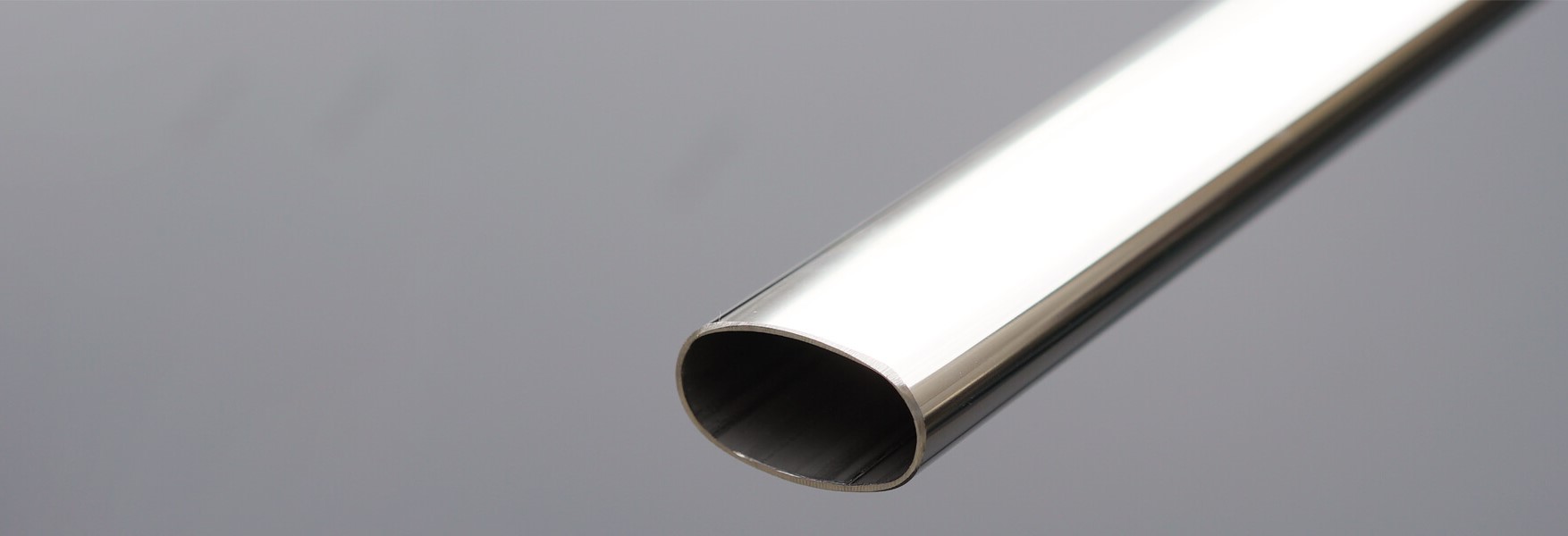

I-Oval Tube uhlobo lwamashubhu ensimbi anomumo okhethekile, ngokwendlela esetshenziswa ngayo, ineshubhu eliyindilinga elihlukile, njengeshubhu lensimbi eliyindilinga, amapayipi ensimbi angenamthungo, amapayipi ensimbi ayisiyindilinga acwebezelayo, amapayipi ensimbi ayisiyindilinga acwebezelayo, amapayipi ensimbi ayisiyindilinga acwebezelayo, amapayipi ensimbi ayisiyindilinga acwebezelayo, amapayipi ensimbi ayisiyindilinga ajwayelekile kanye nezakhiwo ezahlukahlukene zensimbi eziyinkimbinkimbi zemishini yamashubhu ensimbi ayisiyindilinga. Amashubhu ensimbi anembile anoma yiluphi usayizi anobukhulu obungu-1mm-30mm.

Kusukela ezintweni zokwakha, kufaka phakathi i-aluminium oval tube, insimbi oval tube, insimbi engagqwali oval tube nokunye.

Ukusetshenziswa Kwe-Oval Tube?

I-Oval Tube isetshenziswa kabanzi embonini yezimotoukukhishwa kwepayipi eliyindilinga, imihlobiso, izinsiza zokuhamba, ukwakhiwa kwesikhumulo sezindiza, ukwesekwa kwebhuloho, igaraji elinezinhlangothi ezintathu, ukukhangisa kwangaphandle, imishini yokuzivocavoca, izinhlelo zokusebenza zobuhle njengezivikelo ze-DOT, imishini yamandla omoya, ukukhiqizwa kwezimoto, kanye neminye imboni.

Iyini inzuzo ye-Oval Tube?

1. Kusukela kungqimba olungaphandle, kusetshenziswa izendlalelo ezimbili zopende we-hot-dip galvanizing kanye ne-spray ukuze kuvinjelwe ukugqwala. Ingqimba engaphakathi yenziwe ngamapayipi ensimbi angenamthungo anezimbambo zangaphakathi eziphumayo kanye namapayipi epulasitiki e-polypropylene ngokusebenzisa ubuchwepheshe obuhlukile bokucubungula.

2. Ishubhu eliyindilinga liqinile futhi linobumnene obuthile. Akulula ukuguguleka ngenxa yokukhishwa futhi liyamelana nokushaywa. Ukuthembeka kokufakwa kuphezulu, futhi akukho ukugoba ngaphansi kwegesi nokukhanya kwelanga.

3. Ukumelana nesimo sezulu kanye nokumelana nokucindezelwa. Izinga lokushisa lokusebenza kwepayipi lokushisa: 0°C~75°C, izinga lokushisa lifinyelela ku-95°C ngomzuzwana, ingcindezi≤1.5MPa; izinga lokushisa lokusebenza kwepayipi lamanzi okupholisa: 0°C~55C, ingcindezi≤2.0MPa.

4. Ukuvikela ukushisa okuqinile kanye nokumelana nokugqwala. Kufanelekile ukungcwatshwa ebumnyameni kodwa futhi kungafakwa ebumnyameni.

5. Hlanza okungenabo ubuthi, okunempilo, nokuphephile. Imingcele yokusebenza eyahlukahlukene ihlangabezane nezidingo zezindinganiso zekhwalithi zoMnyango Wezempilo.

6. Ingaphakathi libushelelezi futhi lihlanzekile, aligqwali, aliqongeleli, futhi izinga lokugeleza lilonke lilikhulu ngo-25%-30% kunepayipi lensimbi elinobubanzi obufanayo. Akukho monakalo wobubanzi bepayipi ekuhlanganisweni.

7. Kukhethwa ubuchwepheshe obuhlukile bokucubungula. Iphethini yesakhiwo esifana nenethi ehlanganisiwe ikhiqizwa futhi icutshungulwe emgodini wangaphakathi wepayipi lensimbi elingenamthungo, okwandisa kakhulu ukungqubuzana okushelelayo phakathi kwepayipi lensimbi elingaphezulu kanye nepayipi lepulasitiki elingaphakathi.

Ngakolunye uhlangothi, ukungahambisani kokuguquguquka kokushisa phakathi kwamapayipi angaphakathi nangaphandle kuncishiswe ngokufanele. I-coefficient yokwandisa ukushisa kwepayipi eliyindilinga ingu-2.5×(1/100000)/°C, futhi impilo yesevisi iphindwe kahlanu kunepayipi lensimbi eligayiwe elishisayo.

8. Ukufakwa kulula futhi kuthembekile. Ithubhu lixhunywe ngezixhumi zebhodi lodonga ezikhishwa ngokushesha, ezingadingi ukuthungwa, okusindisa isikhathi nomzamo.

Ishubhu lesikwele elikhulu elinobubanzi obukhulu linendawo yokusetshenziswa evamile kakhulu, ngoba ubukhulu bodonga bukhulu kakhulu, ngakho-ke lingathwala ingcindezi enkulu yokusebenza. Ngokuvamile, lingasetshenziswa njengezinto zokusetshenziswa zezingxenye ezingenalutho, ezisetshenziselwa amandla okuthwala kanye nezicelo ezibalulekile zamapayipi.

Eqinisweni, ingasetshenziswa njengamapayipi esakhiwo sezindiza, amapayipi okuhlola i-geological kawoyela ongahluziwe, kanye namapayipi emishini ye-petrochemical. Uma kusetshenziswa amapayipi ensimbi ayisikwele, kumele futhi ahambisane nezinqubomgomo nemithetho efanele. Ngakho-ke, ukusetshenziswa okuyinhloko okuhlukene kudinga ukusetshenziswa kwemininingwane ehlukene kanye namamodeli amapayipi. Lokhu kukhombisa nemfuneko ebalulekile yokusetshenziswa kwamapayipi e-elliptical, ikakhulukazi Uma kuthuthwa izinto eziyingozi kakhulu nezivuthayo, kuyadingeka ukuthola amapayipi ensimbi angenamthungo anemininingwane efanelekile namamodeli, ukuze izingozi zokuphepha zigwenywe ngokufanele.

Ungakhiqiza Kanjani Ama-Oval Tubes?

Isihluthulelo semigqa yenqubo yokukhiqiza ohlotsheni lomkhiqizo. Kusukela ezintweni zokusetshenziswa kuya emikhiqizweni eqediwe, uchungechunge lwezinqubo zobuchwepheshe kumele ludluliswe. Yonke inqubo yalobu buchwepheshe bokucubungula kumele yenziwe ngemishini ehlukahlukene yezimboni, ukushisela ngogesi, izinhlelo zokulawula kagesi, kanye nemishini yokuhlola. Izinhlobo ezahlukene zemishini nemishini zinezindlela ezahlukahlukene zokuhlelwa eziphumelelayo ngokwemithethonqubo ehlukene yenqubo yokukhiqiza.

1. Izinyathelo ezijwayelekile zeshubhu elihlanganisiwe elinomfutho ophezulu: umugqa ovulekayo-ogoqekile oshisayo osicaba-ukusika okuphelile kanye nokuphela-umshini ogoqekile oshisayo ogoqekile-ukukhipha i-loop-Ukwakha-Ukushisela ngogesi-Ukususwa kwama-burrs-Ukutholwa kwe-Die-Flaw-Ukusika i-Fly-Ukuhlolwa kokuqala-Ukuqondisa ipayipi lensimbi elingenamthungo-Ukukhiqizwa kanye nokucubungula kwesigaba sepayipi-Ukuhlolwa kokucindezela-Ukutholwa kwe-Flaw-Ukukopisha nokumboza-Imikhiqizo eqediwe.

2. Ishubhu lensimbi eliyindilinga elihlanganisiwe kahle libizwa nangokuthi ipayipi lensimbi eliyindilinga, okuyinqubo yokukhiqiza ipayipi elingenamthungo.

3. Indlela yokugoba yeshubhu le-elliptical lensimbi engagqwali ngokuvamile isebenzisa indlela yesimiso se-cam. Umphumela wokuthi indlela yesimiso se-cam isetshenziswa kangaki ukucubungula amashubhu e-elliptical ensimbi engagqwali anezindonga ezincane anama-arcs amaningi umphumela wokuqinisekiswa okuningi. Wonke umuntu uke wezwa nge-cam. I-camshaft iyajikeleza, umlandeli uxhunywe ku-contour ye-cam, futhi umlandeli wenza ukunyakaza okuphindaphindayo.

Ngokwalesi simiso: uma nje kuklanywe ama-arcs ama-5 ku-mold, futhi ubude besendlalelo esiphakathi se-arc ngayinye bulingana nobude besendlalelo esiphakathi se-arc yomkhiqizo (ngoba u-R ku-mold one-rebound enkulu incane kune-R kumkhiqizo), I-mold iyisikhungo se-arc esine-engeli enkulu efakiwe njengesikhungo sokujikeleza. Ingxenye eqhutshwayo isebenzisa isilinda. Ngenxa yokucindezelwa kwegesi kanye ne-valve yokukhulula ingcindezi ingasetshenziswa ukulungisa ingcindezi, uma ingcindezi yokugoba inkulu, ungasebenzisa isilinda samandla aphindwe kabili. , Induku yesilinda ixhunywe esihlalweni se-roller esigobile, futhi kukhona i-guide rail ngaphansi kwesihlalo se-roller. Izici ezibalulekile ezithinta ukushwabana kwe-oval tube ijubane lokugoba kanye nezinto ezifakwa ngaphakathi kwe-oval tube.

Ungalawula kanjani isivinini sokugoba? I-valve yokugeleza ehambisanayo ingasetshenziswa ukulawula isivinini sangaphambili nesasemuva sesilinda esiyinhloko. Uma irediyasi yokugoba engu-R yento incane, ukulawula isivinini kufanele kube okufanele.

Ungasika Kanjani Amashubhu Angama-Oval Abe Yimikhiqizo Efunwa Yi-Yur?

Ngokwezidingo ezahlukene zokusika, ungasebenzisa izindlela zokusika ngesandla noma zokusika okuzenzakalelayo. Futhi ukusebenzisa izindlela ezahlukene zokusika izindleko zizohluka kakhulu. Njengomshini wokusika uzosika ipayipi kodwa awukwazi ukugoba ipayipi, umsiki wepayipi futhi ithuluzi elincane lokusika ipayipi elincane.

Uma ufuna ukusebenza kahle okuphezulu futhi kungekho mshini wokusika olinganiselwe wokuklama ukusika, khona-ke i-umshini wokusika ishubhu le-fiber laserkuzoba yisinqumo sakho esingcono kakhulu.

Kungani Umshini Wokusika I-Tube Laser Uyisinqumo Sakho Esingcono Kakhulu Sokucubungula I-Oval Tube?

Ukusika nge-Metal Laser kuyindlela yokusika engasetshenziswa ekuthinteni izinga lokushisa eliphezulu kanye nesivinini esikhulu, akukho ukuphambuka ngesikhathi sokusika, ukunemba kufinyelela ku-0.1mm, kungasika noma yisiphi isimo ebusweni beshubhu lakho eliyindilinga. Umphumela ophelele wokusika nge-laser kushubhu eliyindilinga le-aluminium, ishubhu eliyindilinga lensimbi, ishubhu eliyindilinga lensimbi engagqwali nokunye.

IGolden Laser ingenye yabakhiqizi bemishini yokusika i-laser yeshubhu ehamba phambili eShayina, inikeza isisombululo esiphelele sokusika i-laser senqubo yama-Oval Tubes. Ngezansi ukuhlaziywa kokusetshenziswa komshini wethu wokusika i-laser yeshubhu ngamakhasimende ethu wokusika amashubhu abo e-oval, mhlawumbe nawe unesidingo esifanayo sokusika i-oval tube exhaust njengaye.

Isidingo Sokusika I-Oval Tube Yamakhasimende:

Amashubhu aqandayo angu-89*38 kanye no-114*64mm, Ubude busukela ku-4.5m—6m. Ukusika izimo ezahlukene kanye nesidingo se-"0" Tailer.

Ungahlangabezana kanjani nesidingo sokucubungula okuzenzakalelayo seKhasimende esidingweni sokusika ishubhu le-carbon ovel elinomumo okhethekile?

1. Ukuze ulayishe ngokuzenzakalelayo amashubhu ensimbi, ungasebenzisa umshini wokondla ishubhu, unokulawula okuqondile kwe-servo ukuqinisekisa ukukhethwa okunembile kwamashubhu, bese ukondla ishubhu elicindezela ishubhu - ulinganisa ubude beshubhu. Konke kuqinisekisa ukuthi ipayipi lithunyelwa emshinini wokusika i-laser yepayipi ngokuzinzile nangokunembile

2. Idatha yohlelo lokulawula lwe-PA CNC kanye nohlelo lwe-auto feeder iyabiwa, okuqinisekisa ukunemba kwesikhundla sokugoqa - isikhundla sokusika kuqala - isikhundla sezinto ezilahlekile sihanjiswa ngokunembile. Yonke inqubo icacile.

3. Izinto ezenziwe ngokwezifiso zomhlathi wangaphambili nowangemuva ziqinisekisa ukunemba kokusikwa nge-laser kwepayipi eliyindilinga lensimbi.

4. Ngenxa yokuthi ubude bepayipi bukhulu kakhulu, i-clamp ye-feeder kanye nokusekelwa kwemishini kuzophazamisa, ngakho-ke umsebenzi wethu wokwabelana ngedatha ungaxazulula le nkinga kahle. Sizokhetha ngokuzenzakalelayo ukuthi sizoyikhipha kanjani ipayipi ngokwezimo ezahlukene zepayipi.

5. Uhlelo lokusika nge-laser lushintshwa ngokuzenzakalelayo ngaphandle kokungenelela komuntu.

Ungayixazulula Kanjani Inkinga Yokuklwebheka Kwezinzipho Zepayipi Nokwenziwe Ngokwezifiso Okungase Kuvele Ngesikhathi Sokusika Nge-Laser?

Ngemva kokuhlolwa okuningi, i-radian ekhethekile yokugcina, kanye nokucutshungulwa. Kuxazululwe inkinga yokuklwebheka

Ungaqinisekisa Kanjani Ukunemba Kokusika I-Tube Laser?

Njengoba inqubo yokukhiqiza ipayipi elinomthungo wamehlo ihlukile kwelepayipi elijwayelekile, kunzima kakhulu ukufeza ukuqondeka okujwayelekile kanye nokugoba kwepayipi.

Izinto ezikhethekile kanye nobuciko obuhlukile, ukuhlolwa okuqhubekayo kwamapayipi ayi-100, ukunemba kanye nokwaneliseka kwamakhasimende!

Indlela Yokufinyelela Ukususwa Okungaphelele

Ngokwezici zehluzo zekhasimende, umsila ongu-0 uqinisekisiwe ngaphakathi kwesigamu semitha, umsebenzi wokuvula ikhadi, izilungiselelo ze-Lantek's (Professiona Tube Nesting Software), amandla okubopha alungisekayo e-chuck, njll., ekugcineni kufinyelela umsila ongu-0.

Ividiyo ye-OvalUmshini Wokusika we-Tube LaserIsixazululo Sokusika Okuzenzakalelayo Sereferensi Yakho.

Uma unentshisekelo noma unesidingo esifanayo somshini wokusika i-laser we-oval tube, sicela ukhululeke ukuxhumana nathi.