Koj puas txhawj xeeb tias qhov zoo ntawm kev txiav laser ntawm cov khoom tiav lawm tsis tuaj yeem siv vim muaj ntau yam tsis zoo hauv cov yeeb nkab nws tus kheej, xws li kev hloov pauv, khoov, thiab lwm yam?

Nyob rau hauv tus txheej txheem ntawm kev muag khoomcov tshuab txiav yeeb nkab laser, qee tus neeg siv khoom txhawj xeeb heev txog qhov teeb meem no, vim tias thaum koj yuav ib pawg ntawm cov kav dej, yuav muaj ntau dua lossis tsawg dua qhov tsis sib xws, thiab koj ua tsis taut pov tseg wThaum cov kav dej no raug pov tseg, yuav ua li cas los txhim kho tus nqi siv cov kav dej thiab txo tus nqi pov tseg yog qhov teeb meem uas peb lub tshuab txiav yeeb nkab laser yuav tsum daws.

Yog li, hnub no peb yuav tham txog yuav ua li cas kom tiav qhov kev txiav laser zoo ntawm cov kav dej deformed.

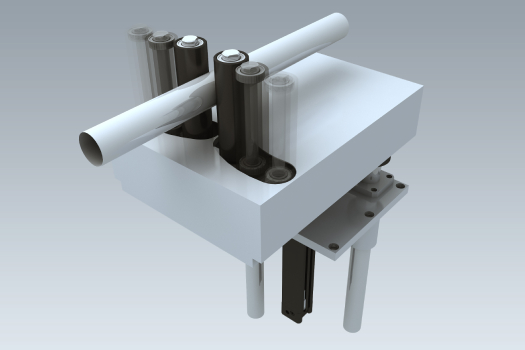

1. Lub qhov pub yeeb nkab, uas yog, lub cuab yeej nruab nrab tsis siv neeg tau ntxiv ua ntej txiav laser, uas tuaj yeem ua tiav kev kho lub cev rau cov yeeb nkab nyias thiab cov yeeb nkab uas tsis muaj kev hloov pauv me ntsis, uas yog, kev kho ua ntej txiav kom txo qhov kev hloov pauv ntawm cov yeeb nkab nws tus kheej. Qhov no ua rau kev puas tsuaj hauv kev txiav laser.

2. Siv lub taub hau txiav fiber ntau capacitive sensing kom ua tiav qhov kev txiav siab, kev rhiab heev, thiab kev txiav ruaj khov.

3. Thaum lub sijhawm txiav, los teb rau qhov xav tau ua cov kav dej tshwj xeeb, xws li cov kav dej oval, cov kav dej DR, thiab lwm yam kav dej tshwj xeeb, peb tau tsim cov thev naus laus zis txiav laser rau cov kav dej tshwj xeeb, cov thev naus laus zis them rov qab tsis siv neeg rau kev cuam tshuam cov kav dej, thiab kev khoov deformation, uas tuaj yeem daws qhov teeb meem ntawm cov kav dej nws tus kheej. Qhov laj thawj yog qhov tsis zoo ntawm kev txiav laser.

4. Rau cov hlau tsis xeb, txhuas alloy, thiab lwm yam yeeb nkab kub siab, los ntawm kev tswj hwm tshwj xeeb thiab kev kho tshuab ces kaum, koj tuaj yeem xaiv cov kab sib txawv, kev tswj hwm lub plawv dhia ces kaum, thiab kev ua haujlwm ces kaum raws li cov yam ntxwv ntawm cov yeeb nkab kub siab thaum lub sijhawm yaj thiab txiav kom txo cov chips. Qhov tshwm sim ntawm backsplash zoo heev txhim kho kev ruaj khov ntawm kev txiav ntse-lub kaum ntse ntse, txo cov pa phem ntawm lub lens tsom, thiab txhim kho lub neej kev pabcuam ntawm lub lens tsom.

5. Thaum txiav cov ces kaum ntse, siv lub zog laser sib txawv, zaus pulse, thiab lub voj voog ua haujlwm pulse tuaj yeem ua kom lub ces kaum ntse txiav zoo thiab txhim kho kev txiav zoo.

Hauv kev xaus lus, txhawm rau kom ntseeg tau tias cov yeeb nkab deformed txiav tau zoo, peb tau koom ua ke R&D thiab kev txhim kho los ntawm kev tsim kho tshuab, laser txiav taub hau mus rau laser txiav software, uas txhim kho qhov kev txiav siab thiab kev ceev ntawm cov yeeb nkab.

Koj muaj lwm yam kev txhawj xeeb dab tsi ntxiv thaum txiav yeeb nkab? Txais tos qhia rau peb paub los ntawm email, thiab peb yuav pab koj daws koj cov teeb meem sai li sai tau.