Ngaba ukhathazekile ukuba umgangatho wokusika nge-laser kwiimveliso ezigqityiweyo awunakusetyenziswa ngenxa yeziphene ezahlukeneyo kumbhobho ngokwawo, ezinje ngokuguquguquka, ukugoba, njl.njl.?

Kwinkqubo yokuthengisaoomatshini bokusika imibhobho yelaser, abanye abathengi baxhalabile kakhulu ngale ngxaki, kuba xa uthenga iqela leepayipi, kuya kuhlala kukho umgangatho ongalinganiyo, kwaye unako't lahla u-wXa le mibhobho ilahliwe, indlela yokuphucula izinga lokusetyenziswa kwemibhobho kunye nokunciphisa izinga lokulahlwa yingxaki ekufuneka isonjululwe ngumatshini wethu wokusika imibhobho yelaser.

Ngoko ke, namhlanje siza kuthetha ngendlela yokugqibezela ukusika imibhobho ekhubazekileyo nge-laser esemgangathweni ophezulu.

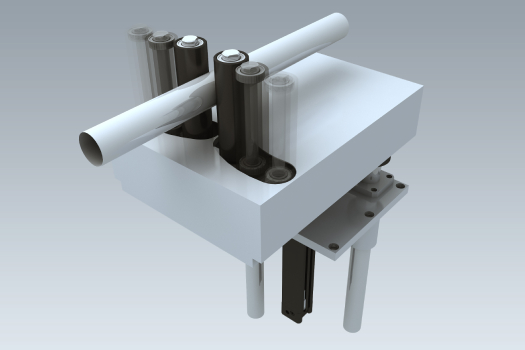

1. Inxalenye yokondla umbhobho, oko kukuthi, isixhobo esizisebenzelayo esidibanisa umbindi ngokuzenzekelayo siyongezwa ngaphambi kokusika nge-laser, esinokwenza ukulungiswa ngokomzimba kwemibhobho emincinci kunye nemibhobho enenguquko encinci, oko kukuthi, ukulungiswa ngaphambi kokusika ukuze kuncitshiswe ngakumbi ukuguquka kombhobho ngokwawo. Oku kukhokelela ekuwohlokeni kokusika nge-laser.

2. Ukusebenzisa intloko yokusika ye-laser yefayibha yokubona i-capacitive ukuze kufezekiswe ukuchaneka okuphezulu, uvakalelo oluphezulu, kunye nokusika okuzinzileyo okuphezulu.

3. Ngexesha lenkqubo yokusika, ukuphendula kwiimfuno zokucubungula iipayipi ezinemilo ekhethekileyo, ezifana neepayipi ezimbhoxo, iipayipi ze-DR, kunye nezinye iipayipi ezikhethekileyo, siye saphuhlisa iteknoloji yokusika i-laser kwiipayipi ezikhethekileyo ezinqamlezileyo, iteknoloji yokuhlawula ngokuzenzekelayo ukuphambuka kwepayipi, kunye nokuguqulwa kokugoba, okunokusombulula ingxaki yombhobho ngokwawo. Isizathu sisiphene sokusika i-laser.

4. Kwintsimbi engagqwaliyo, i-aluminium alloy, kunye neminye imibhobho ye-alloy enobushushu obuphezulu, ngokusebenzisa iteknoloji yokulawula ekhethekileyo kunye netekhnoloji yonyango lwekona, ungakhetha imigca eyahlukeneyo ye-lead-in, ulawulo lokusika i-corner-turn pulse, kunye nemisebenzi yokucubungula ikona ngokweempawu zombhobho we-alloy enobushushu obuphezulu ngexesha lokunyibilika nokusika ukunciphisa iitships. Ukwenzeka kwe-backsplash kuphucula kakhulu ukuzinza kokusika kwe-sharp-engile, kunciphisa ungcoliseko lwelensi yokugxila, kwaye kuphucula ubomi benkonzo yelensi yokugxila.

5. Xa usika iikona ezibukhali, ukusebenzisa amandla ahlukeneyo e-laser, amaza okubetha kwentliziyo, kunye nomjikelo womsebenzi wokubetha kwentliziyo kunokuqinisekisa umgangatho we-contour yokusika iikona ezibukhali kwaye kuphucule ukusebenza kakuhle kokusika.

Ngamafutshane, ukuqinisekisa isiphumo sokusika imibhobho ekhubazekileyo, sidibanise uphando nophuhliso ukusuka kuyilo loomatshini, intloko yokusika nge-laser ukuya kwisoftware yokusika nge-laser, nto leyo ephucula kakhulu ukuchaneka okuphezulu kunye nesantya esiphezulu sokusika imibhobho.

Ziziphi ezinye izinto ozixhalabeleyo malunga nokusika imibhobho? Wamkelekile ukuba usixelele nge-imeyile, kwaye siza kukunceda ukusombulula iingxaki zakho ngokukhawuleza.