Ukhathazekile ukuthi ikhwalithi yokusika nge-laser emikhiqizweni eqediwe ayikwazi ukusetshenziswa ngenxa yeziphambeko ezahlukahlukene epayipini uqobo, njengokuguqulwa, ukugoba, njll.?

Enqubweni yokuthengisaimishini yokusika amapayipi nge-laser, amanye amakhasimende akhathazekile kakhulu ngale nkinga, ngoba uma uthenga iqoqo lamapayipi, kuzohlala kukhona ikhwalithi engalingani, futhi ungakwazit lahla u-wUma la mapayipi elahlwa, indlela yokuthuthukisa izinga lokusetshenziswa kwamapayipi nokunciphisa izinga lokulahla imfucuza yinkinga okumele ixazululwe umshini wethu wokusika amapayipi nge-laser.

Ngakho-ke, namuhla sizoxoxa ngendlela yokuqedela ukusika amapayipi akhubazekile nge-laser esezingeni eliphezulu.

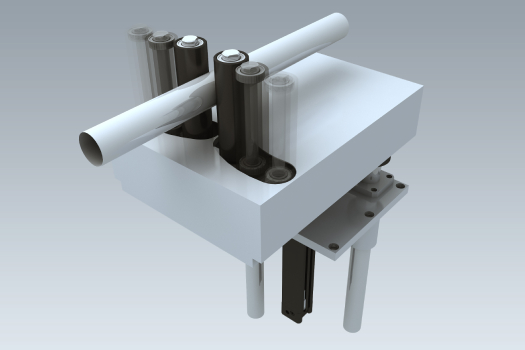

1. Ingxenye yokondla ipayipi, okungukuthi, idivayisi yokufaka i-centering ezenzakalelayo iyengezwa ngaphambi kokusika nge-laser, engenza ukulungiswa ngokomzimba kwamapayipi amancane namapayipi anokuguquguquka okuncane, okungukuthi, ukulungiswa ngaphambi kokusika ukuze kuncishiswe ukujiya kwepayipi uqobo. Lokhu kuholela ekuwohlokeni kokusika nge-laser.

2. Ukusebenzisa ikhanda lokusika le-laser ye-fiber sensing capacitive ukuze kufezwe ukunemba okuphezulu, ukuzwela okuphezulu, kanye nokusika okuzinzile okuphezulu.

3. Ngesikhathi senqubo yokusika, ngenxa yezidingo zokucubungula amapayipi anomumo okhethekile, njengamapayipi ayindilinga, amapayipi e-DR, namanye amapayipi akhethekile, sithuthukise ubuchwepheshe bokusika nge-laser bamapayipi akhethekile anqamula isigaba, ubuchwepheshe bokunxephezela okuzenzakalelayo bokuguquguquka kwamapayipi, kanye nokuguqulwa kokugoba, okungaxazulula inkinga yepayipi uqobo. Isizathu yiphutha lokusika nge-laser.

4. Ngensimbi engagqwali, i-aluminium alloy, kanye namanye amapayipi e-alloy anokushisa okuphezulu, ngokusebenzisa ubuchwepheshe bokulawula obukhethekile kanye nobuchwepheshe bokwelapha amakhona, ungakhetha imigqa ehlukene yokuhola, ukulawula ukushaya kwe-corner-turn, kanye nemisebenzi yokucubungula amakhona ngokwezici zepayipi le-alloy elinokushisa okuphezulu ngesikhathi sokuncibilika nokusika ukunciphisa ama-chip. Ukuvela kwe-backsplash kuthuthukisa kakhulu ukuzinza kokusika kwe-sharp-angle, kunciphisa ukungcola kwelensi yokugxila, futhi kuthuthukisa impilo yesevisi yelensi yokugxila.

5. Uma usika amakhona abukhali, ukusebenzisa amandla e-laser ahlukene, imvamisa yokushaya kwenhliziyo, kanye nomjikelezo womsebenzi wokushaya kwenhliziyo kungaqinisekisa ikhwalithi yokwakheka kokusika kwamakhona abukhali futhi kuthuthukise ukusebenza kahle kokusika.

Ngamafuphi, ukuqinisekisa umphumela wokusika wamapayipi akhubazekile, sihlanganise i-R&D kanye nentuthuko kusukela ekwakhiweni kwemishini, ikhanda lokusika nge-laser kuya kusofthiwe yokusika nge-laser, okuthuthukisa kakhulu ukunemba okuphezulu kanye nesivinini esikhulu sokusika amapayipi.

Yiziphi ezinye izinto ozikhathalelayo ngokusika amapayipi? Siyakwamukela ukusitshela nge-imeyili, futhi sizokusiza ukuxazulula izinkinga zakho ngokushesha okukhulu.