Na o tšoenyehile hore boleng ba ho seha ka laser lihlahisoa tse felileng bo ke ke ba sebelisoa ka lebaka la liphoso tse fapaneng phaepheng ka boeona, joalo ka ho fetoha ha sebopeho, ho kobeha, jj.?

Mothating oa ho rekisamechine ea ho itšeha ka phala ea laser, bareki ba bang ba tšoenyehile haholo ka bothata bona, hobane ha u reka sehlopha sa liphaephe, kamehla ho tla ba le boleng bo batlang bo sa leka-lekane, 'me u ka khona't lahlela wHa liphaephe tsena li lahloa, mokhoa oa ho ntlafatsa sekhahla sa ts'ebeliso ea liphaephe le ho fokotsa sekhahla sa lithōle ke bothata boo mochini oa rona oa ho seha liphaephe tsa laser o lokelang ho bo rarolla.

Kahoo, kajeno re tla bua ka mokhoa oa ho qeta ho seha liphaephe tse nang le sebopeho se senyehileng ka laser ea boleng bo holimo.

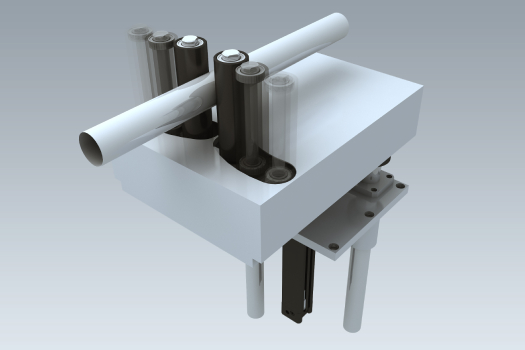

1. Karolo ea ho fepa phaephe, ke hore, sesebelisoa sa ho tsepamisa maikutlo ka boiketsetso se eketsoa pele ho seha ka laser, se ka etsang tokiso ea 'mele bakeng sa liphaephe tse tšesaane le liphaephe tse nang le phetoho e nyane, ke hore, tokiso pele ho seha ho fokotsa ho fetoha ha phaephe ka boeona. Sena se lebisa ho senyeha ha ho seha ka laser.

2. Ho sebedisa hlooho ya ho seha ya laser e utlwang ka capacitive ho fihlella ho nepahala ho hoholo, kutlo e phahameng, le ho seha ho phahameng ka botsitso.

3. Nakong ea ts'ebetso ea ho seha, ho arabela litlhoko tsa ts'ebetso ea liphaephe tse bōpehileng ka ho khetheha, tse kang liphaephe tse oval, liphaephe tsa DR, le liphaephe tse ling tse khethehileng, re ntlafalitse theknoloji ea ho seha ka laser bakeng sa liphaephe tse khethehileng tsa karolo e tšekaletseng, theknoloji ea puseletso ea othomathiki bakeng sa ho sotha liphaephe, le ho kobeha ha sebopeho, e leng se ka rarollang bothata ba phaephe ka boeona. Lebaka ke sekoli sa ho seha ka laser.

4. Bakeng sa tšepe e sa ruseng, motsoako oa aluminium, le liphaephe tse ling tsa motsoako oa mocheso o phahameng, ka theknoloji e khethehileng ea taolo le theknoloji ea kalafo ea likhutlo, u ka khetha mela e fapaneng ea ho kenya, taolo ea ho seha ha pulse ea sekhutlo, le mesebetsi ea ts'ebetso ea likhutlo ho latela litšobotsi tsa phaephe ea motsoako oa mocheso o phahameng nakong ea ho qhibiliha le ho seha ho fokotsa li-chip. Ho hlaha ha backsplash ho ntlafatsa haholo botsitso ba ho seha ha angle e bohale, ho fokotsa tšilafalo ea lense ea ho tsepamisa maikutlo, le ho ntlafatsa bophelo ba tšebeletso ea lense ea ho tsepamisa maikutlo.

5. Ha o seha dikhutlo tse bohale, ho sebedisa matla a fapaneng a laser, maqhubu a pulse, le potoloho ya mosebetsi wa pulse ho ka netefatsa boleng ba sebopeho sa ho seha sekhutlo se bohale le ho ntlafatsa bokgoni ba ho seha.

Ka bokhutšoanyane, ho netefatsa phello ea ho seha ha liphaephe tse nang le sebopeho se senyehileng, re kopantse R&D le ntlafatso ho tloha moralo oa mechini, hlooho ea ho seha ka laser ho ea ho software ea ho seha ka laser, e ntlafatsang haholo ho nepahala ho hoholo le lebelo le phahameng la ho seha liphaephe.

Ke lintho life tse ling tseo u amehileng ka tsona mabapi le ho seha liphaephe? Rea u amohela ho re bolella ka imeile, 'me re tla u thusa ho rarolla mathata a hau kapele kamoo ho ka khonehang.