Fiber Laser Cutting Machine in Transformer Produce

As fiber laser cutting machines becoming popular metal cutting tools in the metal processing industry, many of the manufacturers will choose fiber laser cutting machines to update the quality of their products. Everyone wants a high precise and good appearance products at a good price. The transformer industry also prefers high speed and high accuracy fiber laser cutting machines in their production.

What are Types of Transformers?

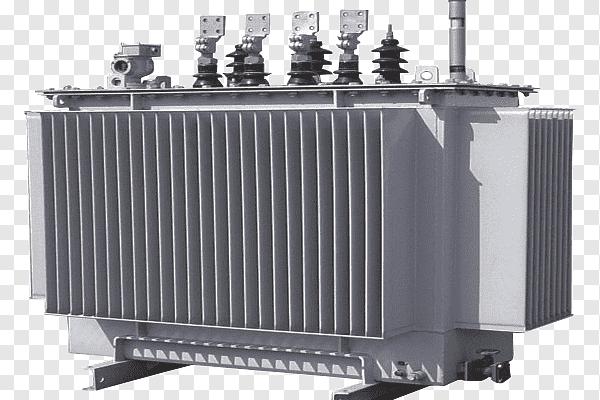

There are many different types of transformers, such as 1. Step up and Step down Transformer, 2. Power Transformer, 3. Distribution Transformer, 4. Instrument transformer comprising current and 5. Potential Transformer, 6. Single-phase and 7. Three-phase transformer, 8. Autotransformer, etc.

What Does an Electrical Transformer Do?

A transformer is an electrical device designed and manufactured to step voltage up or step down. Electrical transformers operate on the principle of magnetic induction and have no moving parts.

What are The Uses of Distribution Transformers?

Distribution transformers are generally used in electrical power distribution and transmission systems. This class of transformer has the highest power, or volt-ampere ratings, and the highest continuous voltage rating. The power rating is normally determined by the type of cooling methods the transformer may use.

How to Make the Transformer by Fiber Laser Cutting Machine?

The electrical transformer box and instrument transformer box are both made of metal materials. It needs to cut different thickness steel into small size by fiber laser cutting machine then welder to weld them together. In the traditional welding method using the electrical welding method, the welding gap is large. Now for many high-quality transformers will also use laser welding machines to weld them together.

What’s the Different Between Plasma and Fiber Laser Cutting Machine in Transformer Industry?

Plasma is cheap and can cut thick metal materials, it is a popular cutting machine for the metalworking industry, but the cutting result is not good, especially the edge will have lots of slags that need to polish again before using them.

Fiber laser cutting edge is smooth and clear, no need to polish and easy for welding, so even the machine cost will higher than plasma, but it save processing and the labor cost. As increase the quality and appearance of the transformer.

That is why a metal sheet laser cutting machine is a necessary metal cutting machine in the transformer industry.

Furthermore, some of the transformer manufacturers start import tube laser cutting machines in the production as well.

The professional Tube laser cutting machine will largely increase the production output.

If you are right in the transformer industry, welcome to contact us for more related laser cutting machine solutions.