factory Outlets for Economical Fiber Laser Cutting Machine - P30120 Pipe & Tube Laser Cutting Machine For Heavy Machinery And Steel Structure – Vtop Fiber Laser

factory Outlets for Economical Fiber Laser Cutting Machine - P30120 Pipe & Tube Laser Cutting Machine For Heavy Machinery And Steel Structure – Vtop Fiber Laser Detail:

Product detail pictures:

Related Product Guide:

Algeria and Iraq shut down internet nationwide to stop students cheating in exams | Ms Plate Cutting Machine For Metal Furniture

Class of ’92 star Ben Thornley gives stark reminder to current Manchester United players | Aluminium Windows And Doors Cutting Machine

We insist on the principle of development of 'High quality, Efficiency, Sincerity and Down-to-earth working approach' to deliver you with great provider of processing for factory Outlets for Economical Fiber Laser Cutting Machine - P30120 Pipe & Tube Laser Cutting Machine For Heavy Machinery And Steel Structure – Vtop Fiber Laser , The product will supply to all over the world, such as: Algeria , Lithuania , Finland , We rely on high-quality materials, perfect design, excellent customer service and the competitive price to win the trust of many customers at home and abroad. 95%products are exported to overseas markets.

Adhering to the business principle of mutual benefits, we have a happy and successful transaction, we think we will be the best business partner.

factory Outlets for Economical Fiber Laser Cutting Machine - P30120 Pipe & Tube Laser Cutting Machine For Heavy Machinery And Steel Structure – Vtop Fiber Laser Detail:

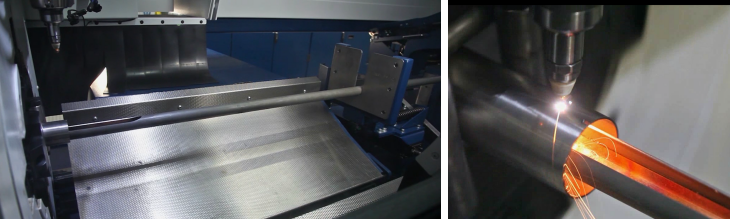

Stainless Steel Round Pipe Fiber Laser Tube cutting Machine P30120

Golden Laser tube/pipe laser cutting machine P30120 adopts most sophisticated fiber laser resonator N-light / IPG from USA, and imported fiber laser cutting head Raytools, combining self-design Gantry CNC machine and high strength welding body. After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability with imported high precision spare parts, like linear guide drive, high-speed servo motor. Aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity.

Machine Features

Integrated main body makes the whole machine with good concentricity, verticality and precision Dual motive chucks are compatible with a variety of pipe without adjusting jaws Optimized claw holding pressure makes tube wall thickness within 1mm without deformation Innovative one-way air control claw tightness helps extend cylinder life Visual scale adjustable support lifting device saves feeding time, ensures concentricity, prevents pipe swinging Integrated circuits, streamline laying provides easy maintenance and low failure rate Automatic boundary, automatically find center, automatic compensation Adjustable frequency perforation High damping bed, good rigidity, high speed and acceleration Automatic bundle loader for option which saves labor and loading time, achieve mass production purpose The world’s leading fiber laser resonator and electronic components to ensure machine superior stability Professional pipe laser cutting control system Germany PA and nesting software Spain Lantek

Machine Core Parts

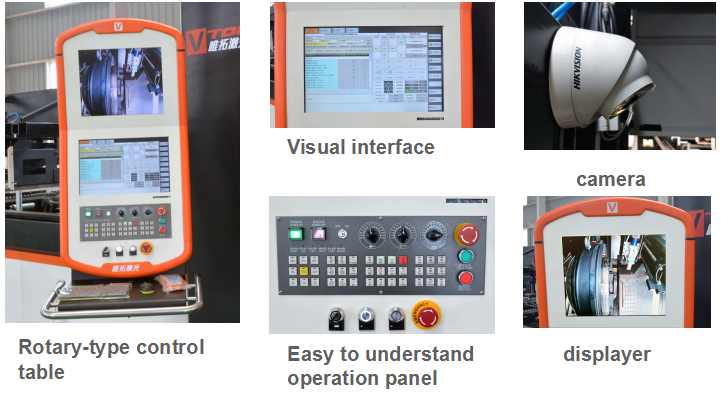

Convenient operation

| Advanced chuck mounting system |

|

| * Double Synchronous Rotation Powerful Chucks: Through the change of gas path, in the place of common-used four-jaws linkage chuck, we optimize into dual claw coordination chuck. Within the scope of the stroke, when cutting tubes in different diameters or shapes, It can be fixed and centered successfully at once, no need to adjust the jaws, easy to switch for different diameters of tube materials , and greatly save installation time.* Large stroke: Increase the retracting stroke of pneumatic chucks and optimize it to be double-sides moving range of 100mm (50mm on each side); saving loading and fixting time greatly. |

| Automatic Floating Support |

|

| * The floating support is controlled by the servo motor and it can adjust the support point according to the pipe diameter quickly. |

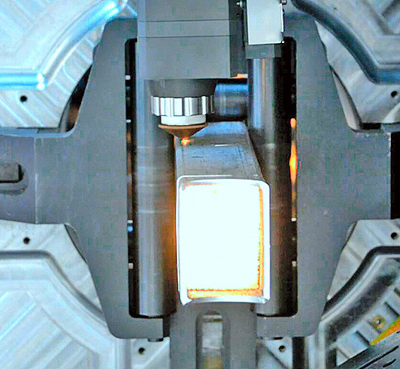

| Three-axis linkage | Welding seam recognition | Automatic correction |

|

|

|

| During the cutting head movement.,feeding axis(X axis)、chuck rotation axis(Y axis)、cutting head(Z axis )three-axis linkage | Identify welding Seam,to aviod welding seam during cutting process automatically, and prevent holes from popping | For the bent and deformed pipe,the automatic correction function can realize the segmented edge search,automatic correction find the center point of the curved tube to cut, and ensure the cutting precision. |

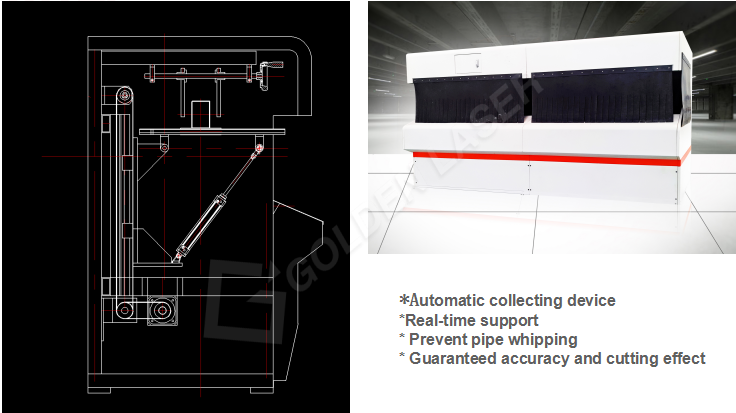

| Hardware——Floating support |

|

| *Automatic collecting device*Real-time support* Prevent pipe whipping

* Guaranteed accuracy and cutting effect |

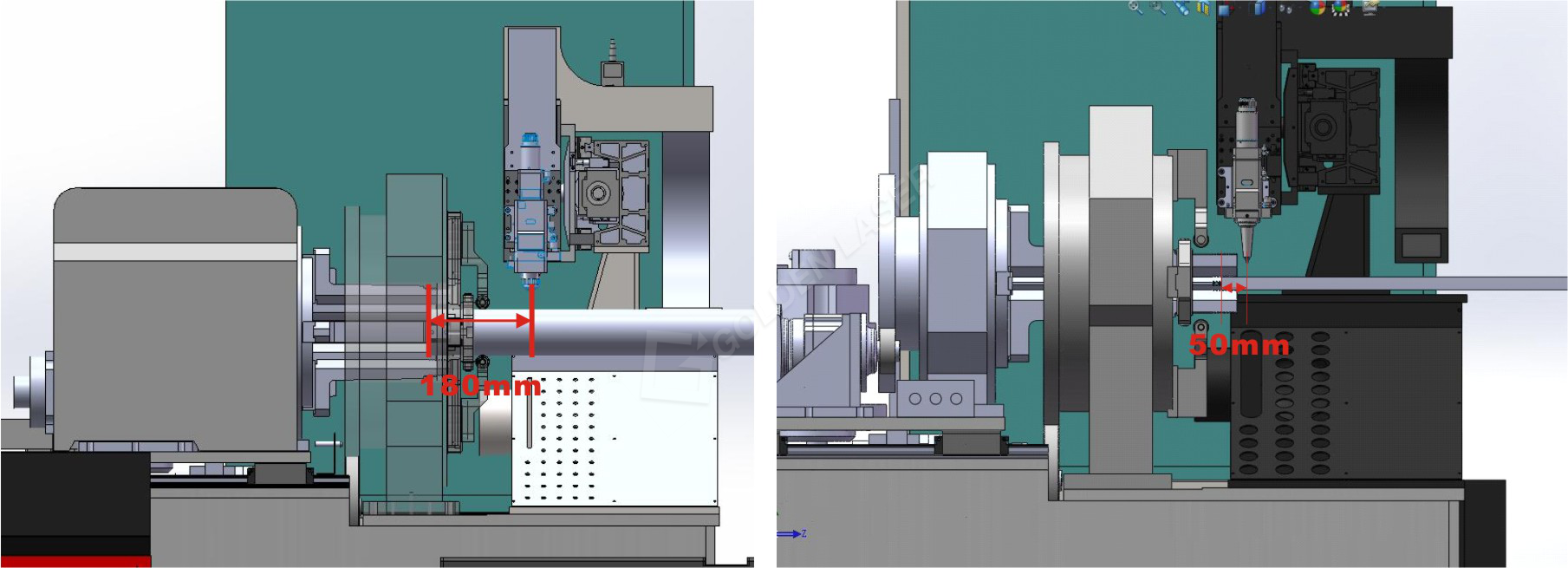

| Hardware——wastage |

|

| When cutting to the last part of the material, the front chuck is automatically open, and the back chuck jaw passes through the front chuck to reduce the cutting blind area.Tubes with diameters less than 100 mm and wastage materials at 50-80 mm;Tubes with diameters more than 100 mm and wastage materials at 180-200 mm |

| Optional – the third axis cleaning inner wall device |

|

| Due to the laser cutting process, the slag will inevitably adhere to the inner wall of the opposite pipe. In particular, some pipes with smaller diameters will have more slag. For some of high applications demands, the third shaft pick-up device can be added to prevent slag from adhering to the inner wall. |

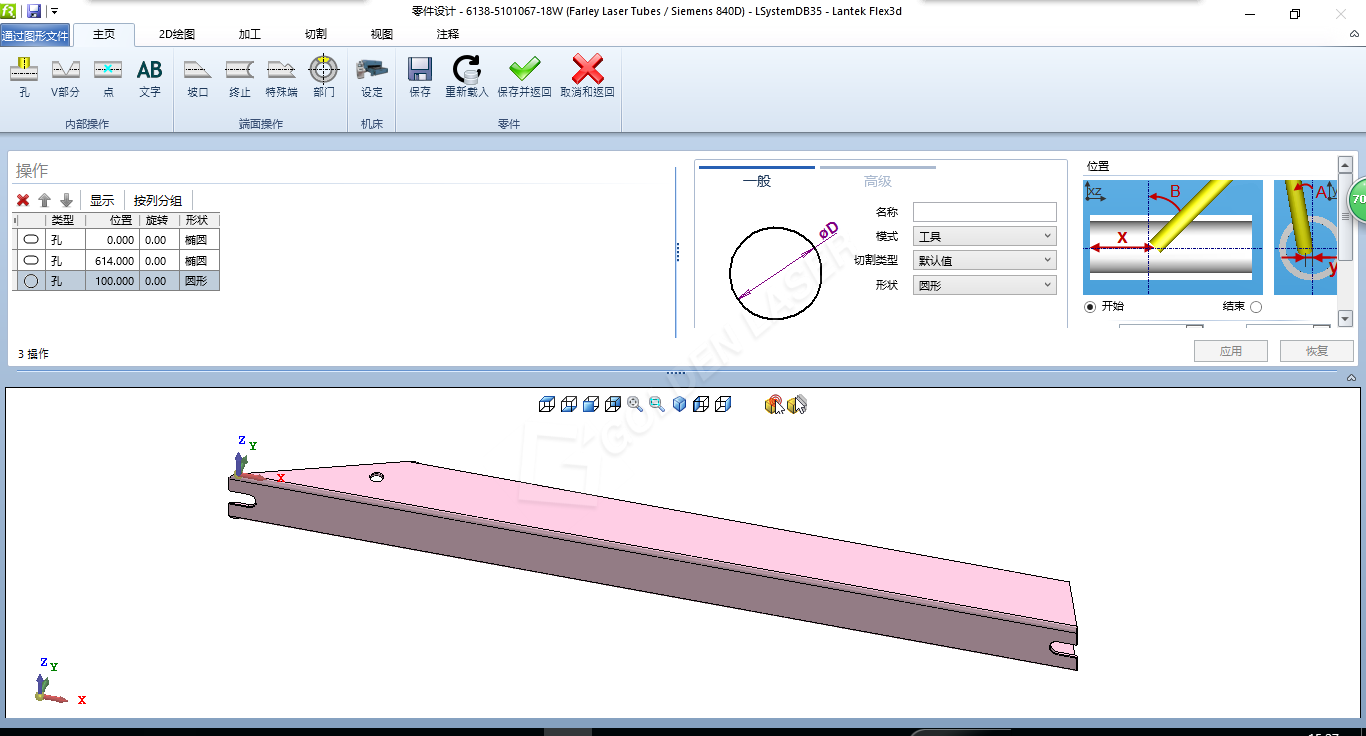

Spanish Lantek software - Focus on tube parts design module

P30120 Machine In Our Customer Site

Product detail pictures:

Related Product Guide:

Made In America: The Under-The-Radar Company That Helps Airplanes Fly | 2000w Laser Cutting Machine

The Aussie open source effort that keeps a million drones in the air | 2000w Laser Cutting Machine

Each individual member from our large performance revenue crew values customers' needs and company communication for factory Outlets for Economical Fiber Laser Cutting Machine - P30120 Pipe & Tube Laser Cutting Machine For Heavy Machinery And Steel Structure – Vtop Fiber Laser , The product will supply to all over the world, such as: Morocco , Rwanda , Senegal , Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question things they do not understand. We break down those barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .