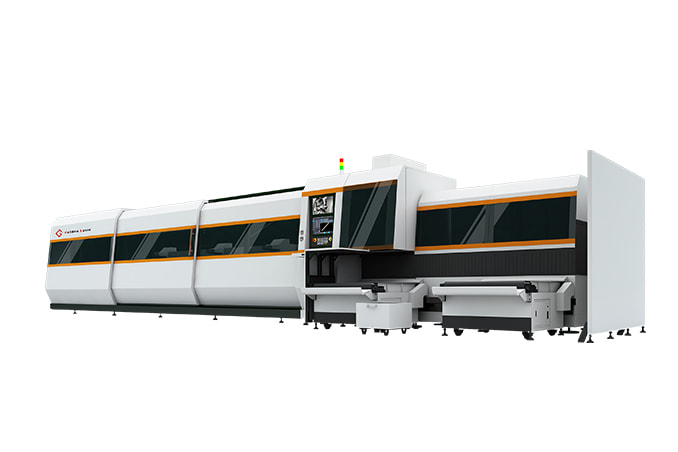

P Series Tube Laser Cutter Technical Parameters

| Model number | P2060A / P2080A / P3080A | ||

| Laser power | 3000w / 4000w (1000w, 1500w, 2000w, 2500w optional) |

||

| Laser source | IPG / nLight fiber laser resonator | ||

| Tube length | 6000mm, 8000mm | ||

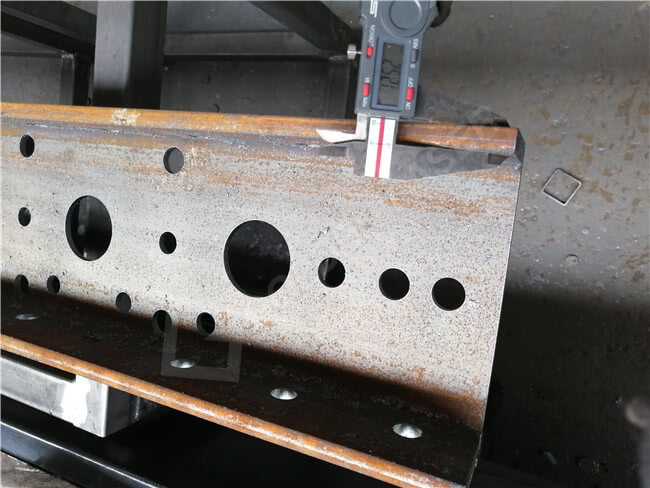

| Tube diameter | 20mm-200mm / 20mm-300mm | ||

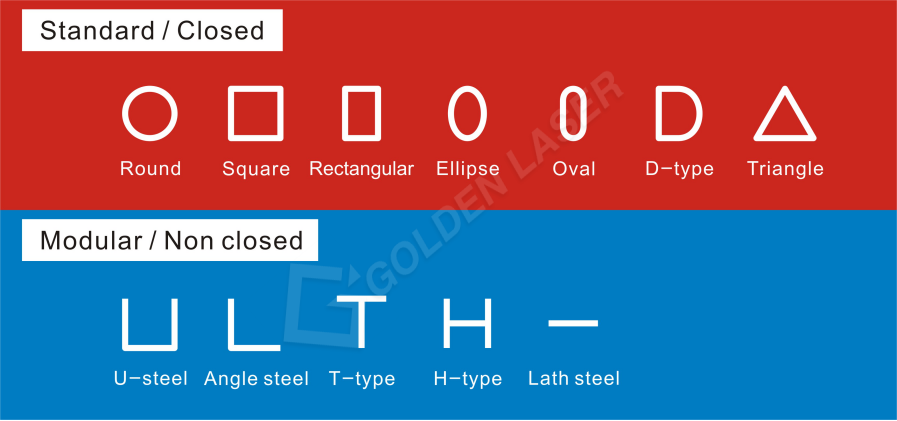

| Tube type | Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) |

||

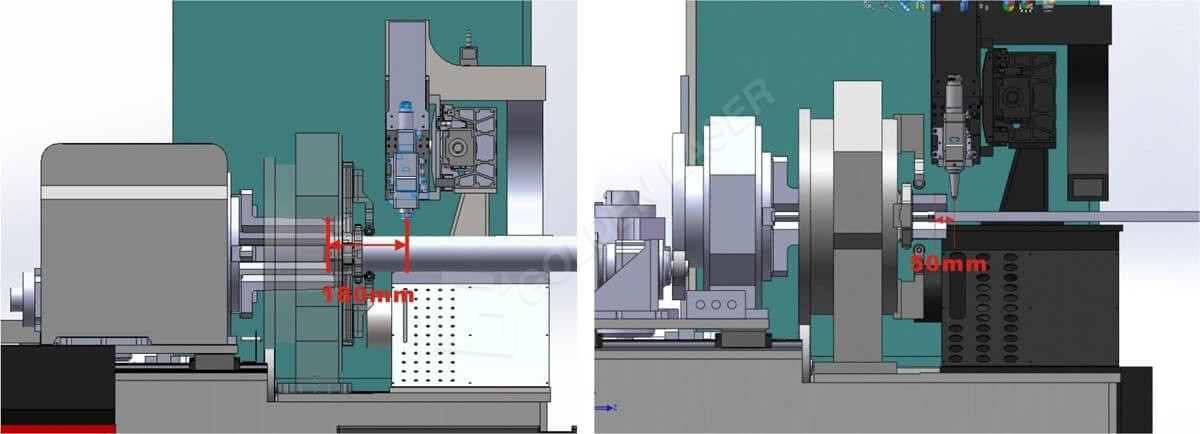

| Repeat position accuracy | ± 0.03mm | ||

| Position accuracy | ± 0.05mm | ||

| Position speed | Max 90m/min | ||

| Chuck rotate speed | Max 105r/min | ||

| Acceleration | 1.2g | ||

| Graphic format | Solidworks, Pro/e, UG, IGS | ||

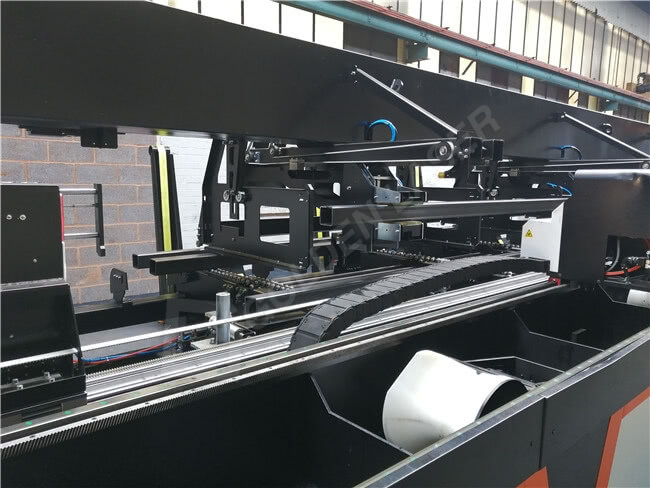

| Bundle size | 800mm*800mm*6000mm | ||

| Bundle weight | Max 2500kg | ||

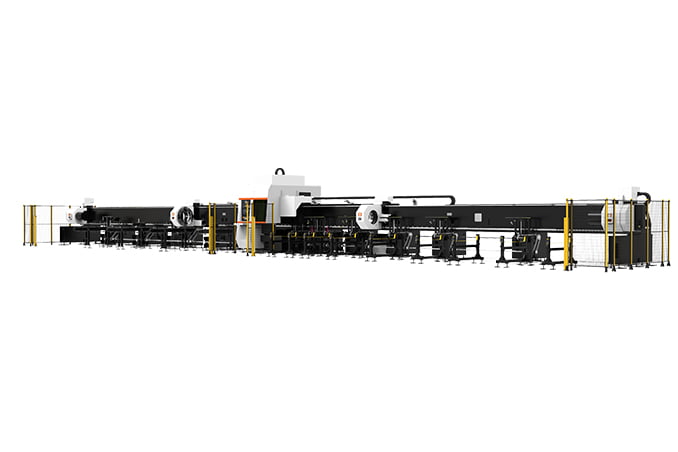

| Other Related Professional Pipe Laser Cutting Machine With Automatic Bundle Loader | |||

| Model number | P3060 | P3080 | P30120 |

| Pipe processing length | 6m | 8m | 12m |

| Pipe processing diameter | Φ20mm-200mm | Φ20mm-300mm | Φ20mm-300mm |

| Applicable types of pipes | Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) |

||

| Laser source | IPG/N-light fiber laser resonator | ||

| Laser power | 700W/1000W/1200W/2000W/2500W/3000W/4000W | ||

P2060A Machine Collocation

| Article Name | Brand |

| Fiber laser source | IPG (America) |

| CNC controller | HIGERMAN POWER AUTOMATION (China + Germany) |

| Software | LANTEK FLEX3D (Spain) |

| Servo motor and driver | YASKAWA (Japan) |

| Gear rack | ATLANTA (Germany) |

| Liner guide | REXROTH (Germany) |

| Laser head | RAYTOOLS (Switzerland) |

| Gas proportional valve | SMC (Japan) |

| Main electric components | SCHNEIDER (France) |

| Reduction gear box | APEX (Taiwan) |

| Chiller | TONG FEI (China) |

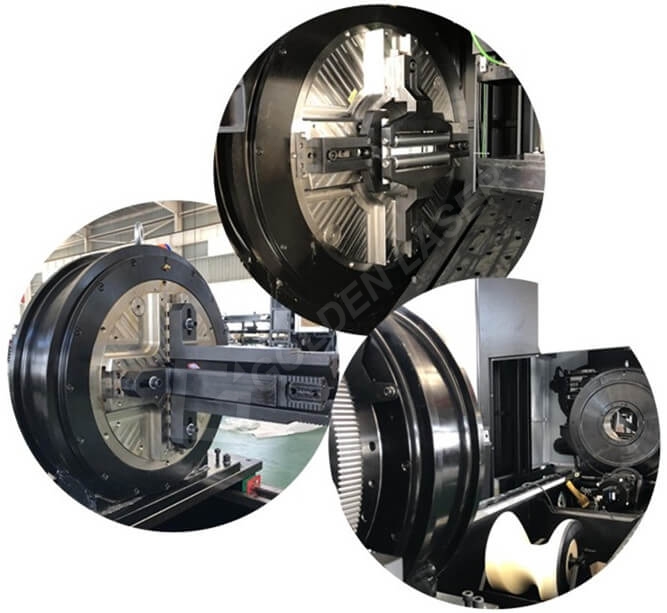

| Rotate chuck system | GOLDEN LASER |

| Automatic bundle loading system | GOLDEN LASER |

| Automatic unloading system | GOLDEN LASER |

| Stabilizer | JUN WEN (China) |

3000W Fiber Laser Cutting Machine (Metal Sheet Thickness Cutting Ability)

|

Material |

Cutting Limit |

Clean Cut |

|

Carbon steel |

22mm |

20mm |

|

Stainless steel |

12mm |

10mm |

|

Aluminum |

10mm |

8mm |

|

Brass |

8mm |

8mm |

|

Copper |

6mm |

5mm |

|

Galvanized steel |

8mm |

6mm |

4000W Fiber Laser Cutting Machine (Metal Sheet Thickness Cutting Ability)

|

Material |

Cutting Limit |

Clean Cut |

|

Carbon steel |

25mm |

20mm |

|

Stainless steel |

12mm |

10mm |

|

Aluminum |

12mm |

10mm |

|

Brass |

12mm |

10mm |

|

Copper |

6mm |

5mm |

|

Galvanized steel |

10mm |

8mm |