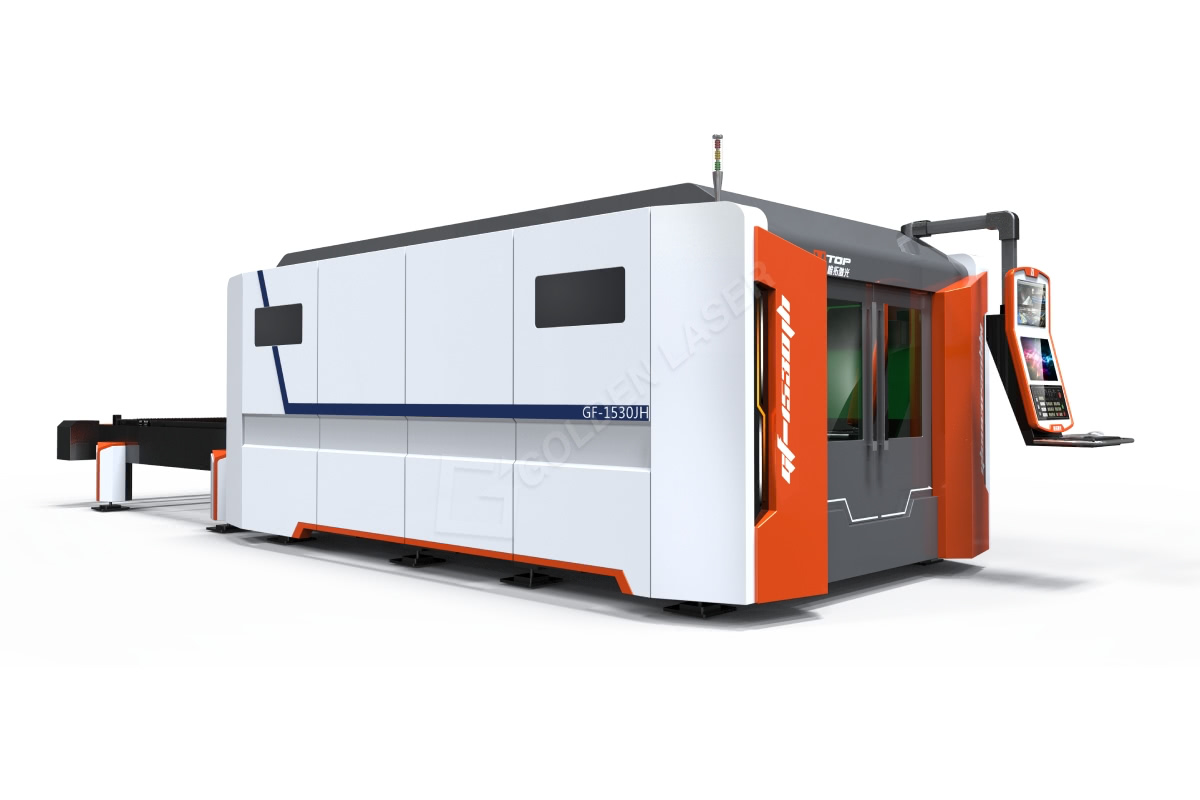

| Model number: | M4 / M6 / M8 / M12 (GF-2060JH / GF-2040JH / GF-2560JH) |

| Laser source: | Raycus / Max / IPG/ N-light fiber laser generator |

| Laser Source Power: | 20000w (20kw laser)-30000w (30kw Laser) |

| Working Area: | 2000*4000mm, 2000*6000mm, 2500*8000mm ,2500*12000mm |

| Repeat Position Accuracy | 0.03mm |

| Position Accuracy | 0.05mm |

| Position Speed | 160m/min |

| Acceleration | 2g |

| Electric Power Supply: | AC220V 50/60HZ ; AC380V 50/60HZ |