As an open coastal city and Jiaodong machinery manufacturing and information technology base,Yantai has unparalleled advantages in its cooperation with Japan and South Korea’s industries by its unique locational advantages. It is the main carrier for Japan and South Korea’s industrial transfer and is the bridgehead with Japan and South Korea’s economy.

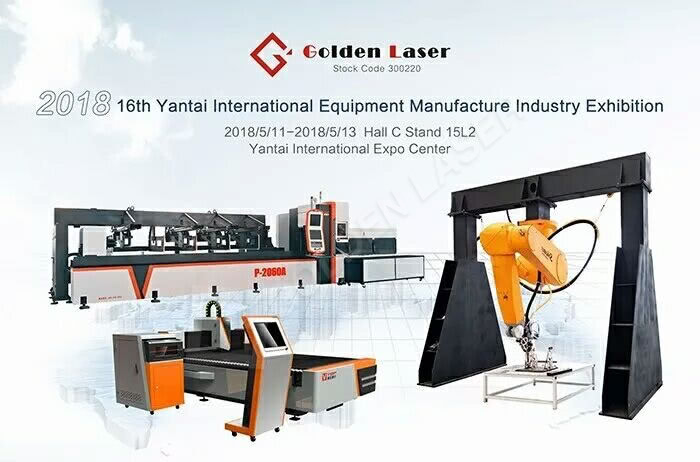

The 2018 16th Yantai International Equipment Manufacture Industry Exhibition will be held in May 11th-13th, we Golden Laser as the laser machine manufactuer will attend this exhibition, this time we will show one Professional Pipe Laser Cutting Machine P2060A with auto bundle loader system, one Sheet Metal Laser Cutting Machine GF-1530, and aslo the Robot Arm Laser Welding Machine. Our stand is Hall C 15L2, warmly welcome your visiting.

Exhibits Preview 01

Professional Pipe Laser Cutting Machine P2060A

Pipes and profiles are widely used in all walks of life and are closely related to everyone’s life. For example, furniture, clothing display racks, large stadiums, fitness equipment, agricultural machinery, passenger cars, forklifts, oil screens, and other industries. With the market demand continues to expand, the processing market for pipes and profiles are also growing. The traditional processing methods can no longer meet the requirements of high-speed market development and low-cost production modes. Therefore, Golden laser pipe cutting machine came into being.

Machine Features

P series laser cutting machine is new type CNC pipe laser cutting machine independently designed and developed by Golden Laser. The machine has excellent configuration, high processing efficiency and precision, stable and reliable operation. The all-through numerically-controlled rotary table is the main features. It can support large pipe with diameter of Ø300mm. Two high-precision rotary tables are driven by dual-drive synchronously, so the pipes are in good state without deformation during processing. The being processed pipes are with high precision, and it can cut round, square, triangular, rectangular, elliptical and various kinds of shaped tubes.

Main Functions

Processing materials: maximum pipe cutting thickness ≤ 20mm (carbon steel) (depending on different materials), the stroke can reach 12m or more.

1. Cutting cylindrical intersecting lines of different directions and diameters on pipes, and meet the requirements of perpendicular and non-biased intersection of branch pipe axis and main pipe axis.

2. Cut oblique end face at the end of the tube.

3. Cut branch pipe intersection line end which is crossed with the ring main pipes

4. Cut variable angle groove face

5. Cut square hole on the round tube and waist round tube

6. Cut off many types of steel pipe

7. Cut a variety of graphics in the square tube

Applied materials

The pipe laser cutting machine is sutiable for cutting carbon steel, stainless steel, copper, aluminum, alloy steel, spring steel, galvanized, copper-plated, gold, silver, titanium and other metal pipe.

Applied industries

And it mainly used in equipment like fitness, furniture, showcase, medical, exhibition and agricultural machinery, structural parts, bridges, ships, automotor parts, structural sections and pipe processing.

What’s more, the optional auto bundle loader system makes pipe quality better. Through continuous exploration and technological innovation, Golden Laser will work together with you to improve the machine.

Exhibits Preview 02

2500W Sheet Metal Laser Cutting Machine GF-1530

GF-1530 series fiber laser cutting machine is the new generation product with updated new appearance and different configuration based on original model, It’s mainly used in sheet metal working, advertising&sign, furniture, automotive and related industries.

Main features

Open design provides easy loading and unloading

Single working table saves space

Drawer style tray makes easy collecting and cleaning for the scraps and small parts

Gantry double driving structure, high damping bed, good rigidity, high speed and acceleration

The world’s leading fiber laser resonator (single mode) and electronic components to achieve thin metal sheets high speed cutting at the same time ensure machine superior stability

Applied materials

Specially for carbon steel, stainless steel, galvanized steel, alloy, titanium, aluminum, brass, copper and other metal sheets.

Applied industries

This model is specially for sheet metal processing, advertising sign, electrical cabinet making, mechanical parts, kitchen utensils, automobiles, machinery, metal crafts, saw blades, electrical parts, eyewear industry, spring sheet, circuit board, electric kettle, medical micro electronics, hardware, knife measuring tools, hollow lighting, door and window decoration and other industries.

Exhibits Preview 02

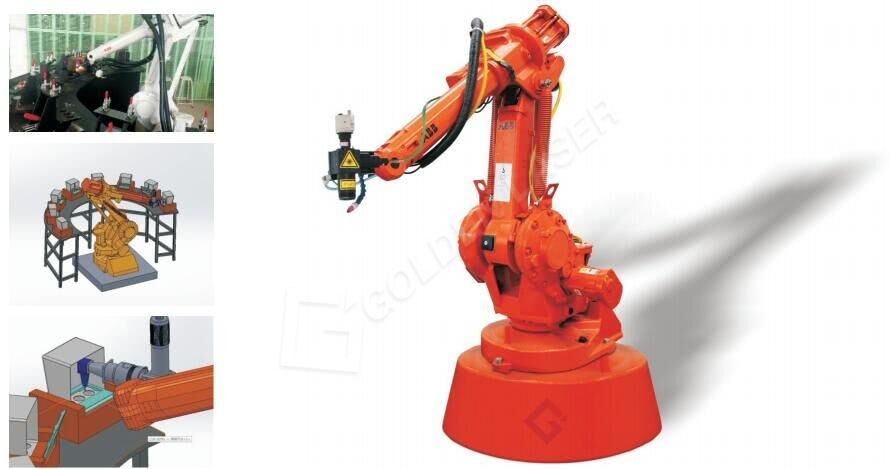

3Robot Arm Laser Welding Machine

Laser welding has the superiority of small welding spot diameter, narrow weld seam and excellent welding effect. After welding,there is no need further treatment or merely simple further treatment. Furthermore, laser welding is applicable to a large scale of materials and can weld various different materials. There advantages enable laser welding be widely used in varieties of precision welding processes.

Main features

1) It perfectly integrated the world famous robot arm like ABB, Stabuli, Fanuc and fiber laser welding machine that can realize automated production to the maximum.

2) 6-axis cooperation makes a large working area and can reach long distance so as to perform welding process along any track within the working space.

3) Due to the compact structure and slim robot wrist, it can realize high performance operation even if the working place has lots of restriction.

4) Process speed and position can be adjusted to achieve the best manufacturing precision with high yield.

5) Low noise, long routine maintenance intervals, long lifespan.

6) The robot arm can be controlled by handheld terminal.

Applied materials

Laser welding material is mainly metallic material: such as stainless steel, aluminum alloy, carbon steel, mild steel, brass, copper, galvanized sheet, rare metals, etc.

Applied industries

Fiber laser welding is widely applied in batteries, mold, electronics, hardware, household appliances, bathroom accessories, super capacitors, automotive parts, micro electronics, aerospace, solar, glasses, jewelry, medical equipment, instrumental devices, optical communications etc.