| Model | P120 |

| Pipe cutting material | Steel Round pipe |

| Diameter of cut pipe | Φ20-Φ120mm |

| Length of cutted pipe | 30-1500mm |

| Max. cutting thickness | ≤5mm |

| Loading Pipe length | 2000-6000mm |

| Processing speed | Depends on the laser source power and material |

| Repeat Positioning Accuracy | ±0.03mm |

| Positioning Accuracy | 0.05mm |

| Cutting System | WEIHONG |

| Loading weight of single tube | 25Kg |

| Auto bundle loading weight | 600Kg |

| Power supply | 3 phases 380V 50/60HZ |

| Machine size | 2400*1150*1800mm |

| Machine floor size | 10500*2000*1800mm |

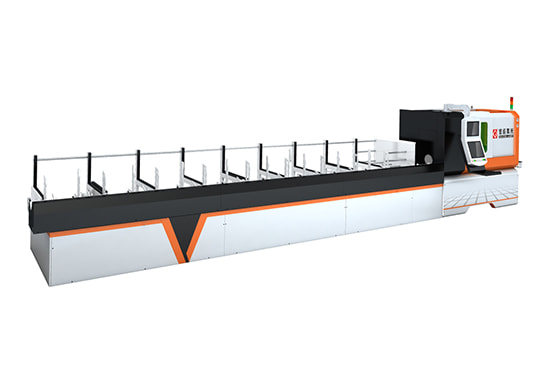

Round Metal Tube Fiber Laser Cutting Machine P120

Machine Features

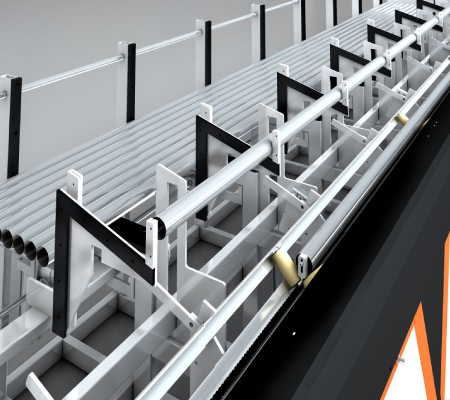

1. Round Pipe Automatic Loading

Saving labor and improving process efficiency.

This machine is divided into two parts: laser cutting and intelligent feeding.

After the metal pipe is simply arranged, they enter into the feeding part. The system automatically and continuously loads pipes during laser cutting, and automatically recognizes the material head between the two raw materials and cuts them.

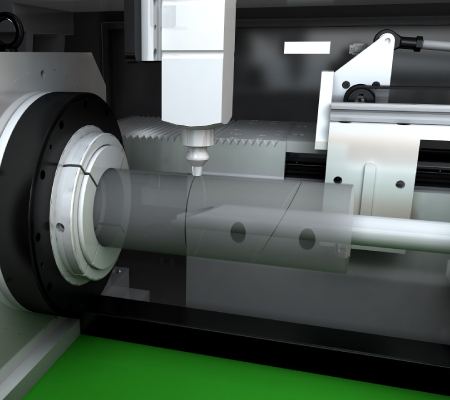

2. Fast cutting speed, multiple functions (Slag Remove Optional), and improved efficiency.

A variety of cutting processes: not only the blanking ability, but also a variety of cutting processes such as hole cutting, cutting, and bevel cutting, covering the process requirements of the application industry.

3. Less wasted pipes, saving material, and reducing process.

When the pipe cannot be fed at one time, the subsequent pipes will continue to promote the current pipe feeding and continue to complete the tailing cutting.

The normal wasted pipe length of the machine is ≤40mm, which is far lower than the ordinary laser cutting machine in which the wasted pipe length is 200- 320mm.

Less material loss, eliminating the need for wasted pipe processing.

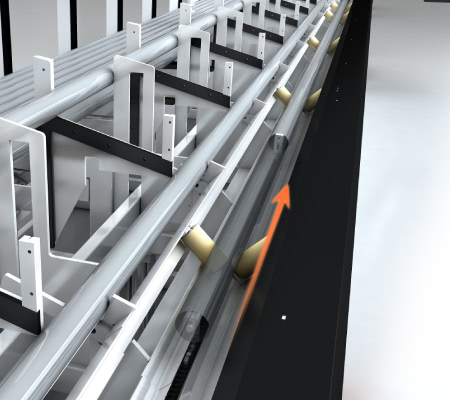

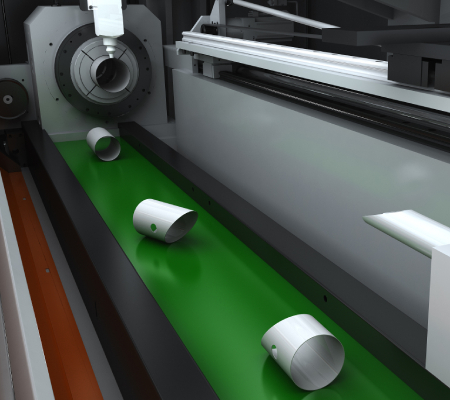

4. Conveyor Belt Easy To Collect The Finished Pipe.

The finished round tube will transfer by the conveyor belt and fall into a collection box according to the customer's demand.

Easy to move for the next processing demand.

Fiber Laser Cutting Machine Advantages

Compare with the sewing machine, fiber tube laser cutting machine with more excellent cutting result, no slag during cut the stainless steel, no need second process to clean, no water pollution, no big noise, with high precision. Golden Laser fiber laser cutting machine will be your best choice to insteady of traditional sawing machine in the motor parts industry, elbow cutting, pipe fitting industry and so on.

P120 1500w Tube Laser Cutting Capacity (Metal Cutting Thickness)

|

Material |

Cutting Limit |

Clean Cut |

|

Carbon steel |

14 mm |

12 mm |

|

Stainless steel |

6 mm |

5 mm |

|

Aluminum |

5 mm |

4 mm |

|

Brass |

5 mm |

4 mm |

|

Copper |

4 mm |

3 mm |

|

Galvanized steel |

5 mm |

4 mm |

P120 Round Tube Laser Cutting Machine Video

Not Only Cut Round Tube?

Try Hots Model P1260A (Automatic small and middle-size tube laser cutting machine)

Material & Industry Application

Applicable Materials

Stainless steel, carbon steel, aluminum, brass, copper, alloy steel and galvanized steel round tubes etc.

Applicable Types Of Tubes and Industry

This model is especially for round tube truncating and holes drilling, and it aims to replace the sawing machine in the motor parts, elbow cutting and pipe fittings industry.

Motorcycle Parts Industry: can be integrated into automated production lines: highly automated production methods, so the equipment is also integrated into the processing automobile production line.

Elbow Connector Industry: not afraid of the large number and types: simple operation mode, in line with multiple batches and multiple types of elbow connector production and processing tasks, fast and free switching.

Metal Sanitary Ware Industry: the quality of both inside and outside of the tube is in line with the demand for higher-end products: fiber laser cutting tube has no damage to the surface of the tube, and the inside of the tube can be protected by automatic slag removal. The processed metal sanitary fittings will fit the high quality of future high-end sanitary products Claim.

Stair Handrails and Door Industries: low-cost, value-added and low-profit industries: Compared with traditional processing methods, the use of a special fiber laser tube cutting machine for round tubes has lower cost and higher processing efficiency, and the same product can obtain higher profits.

Metal Stroller Industry: more extensive application capabilities: the ability of the oblique cutting process can well solve the processing requirements of the splicing end between the metal stroller round pipe workpieces.

Machine Technical Parameters

Related products

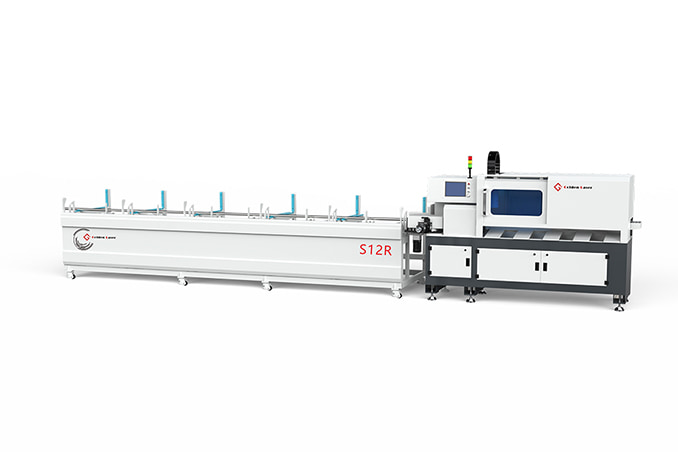

-

S12R

Top Rated Fiber Laser Round Tube Cutting Machine For Sale -

L12MAX

Side-mounted Small Tube Laser Cutting Machine -

S09 / S12 / S16

Smart Tiny Tube Laser Cutting Machine