| Model number | P2060 / P3080 |

| Tube length | 6000mm, 8000mm |

| Tube diameter | 20mm-200mm, 20mm-300mm |

| Laser source | imported fiber laser resonator IPG / N-Light |

| Laser resonator | Nlight, IPG or Raycus |

| Servo Motor | 4 servo motors for all axial movement |

| Laser source power | 2000w 3000w (1000w 1500w 2500w 4000w optional) |

| Position accuracy | ±0.03mm |

| Repeat position accuracy | ±0.01mm |

| Rotating speed | 120r/min |

| Acceleration | 1.2G |

| Cutting speed | depend on material, laser source power |

| Electric power supply | AC380V 50/60Hz |

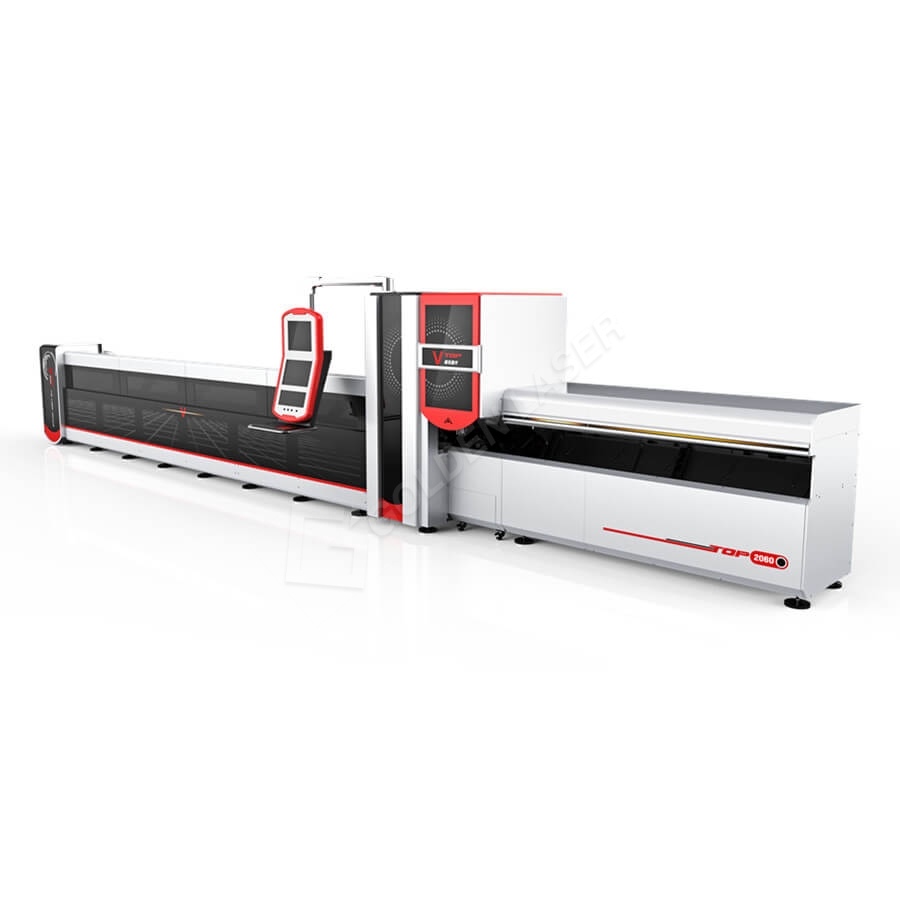

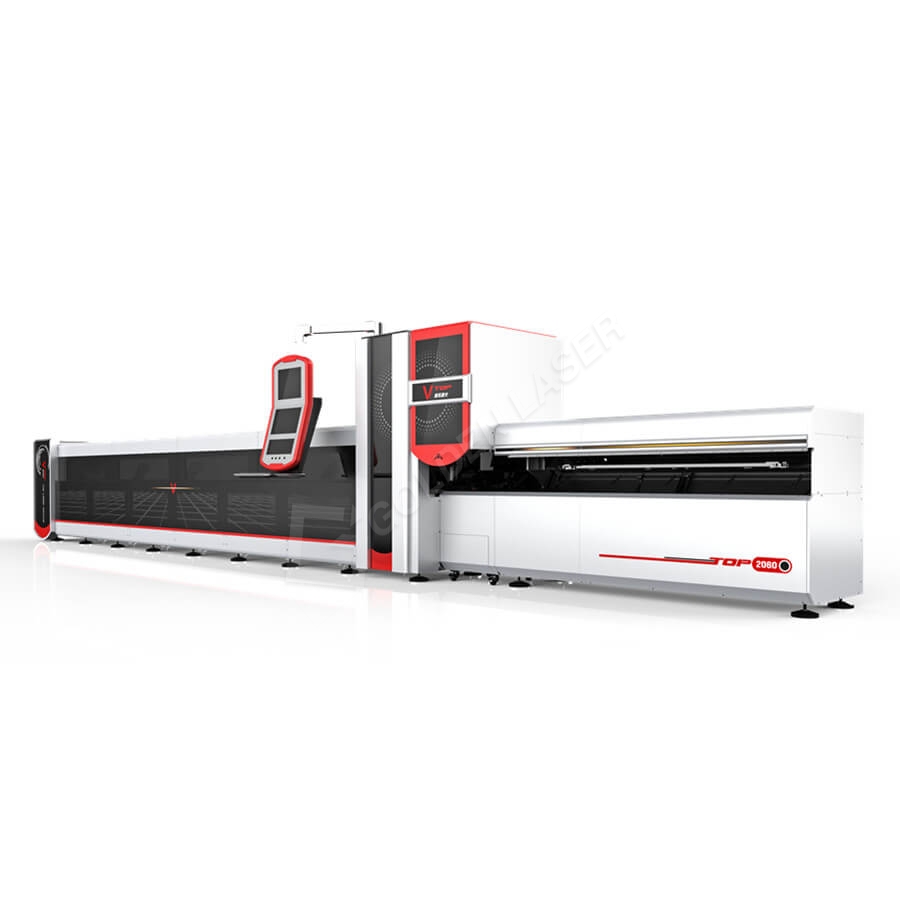

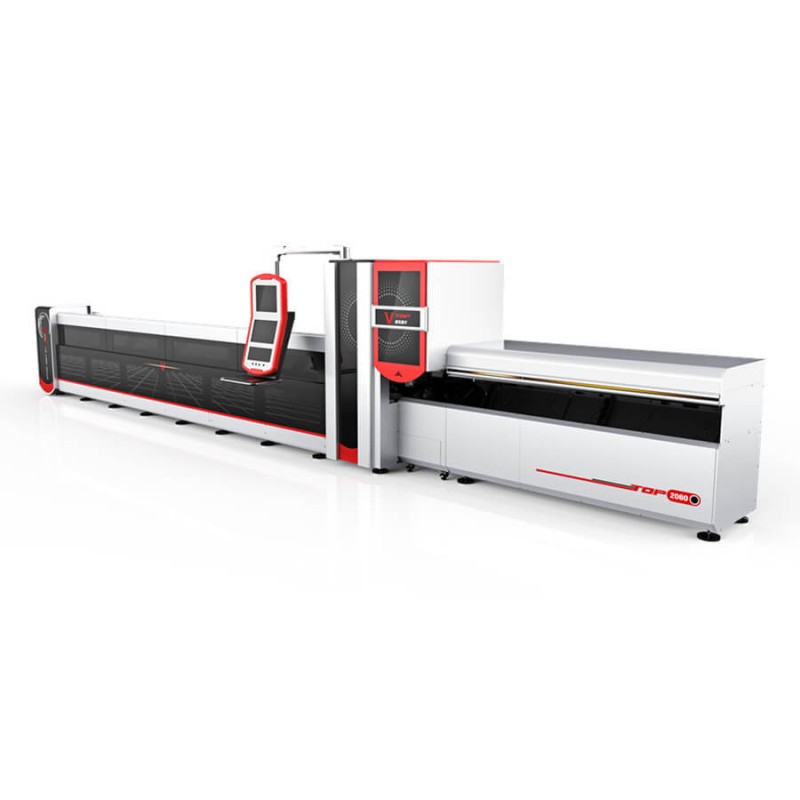

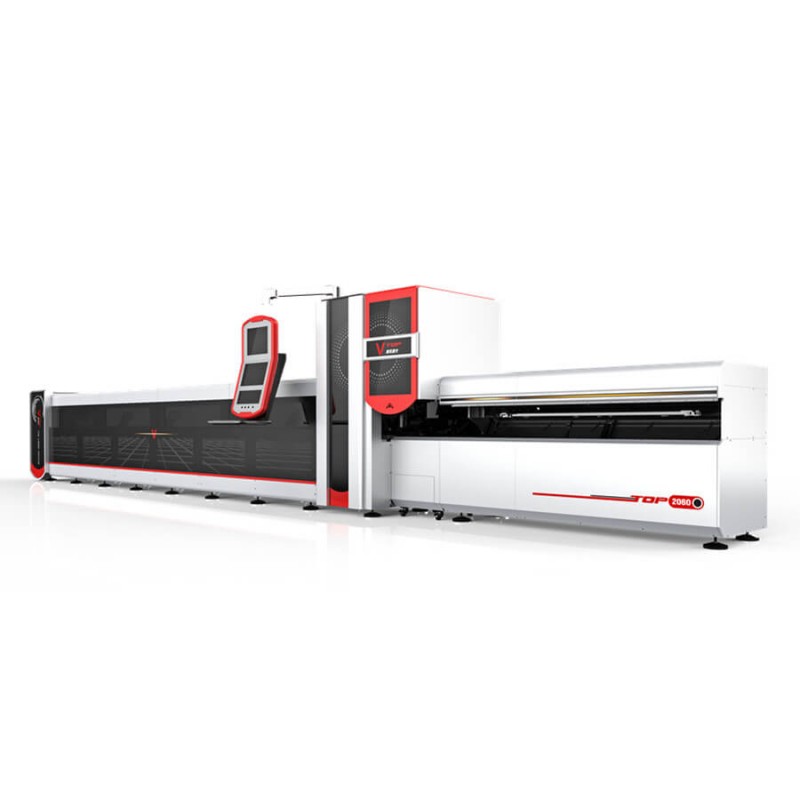

2000w 3000w Fiber Laser Tube Cutting Machine

P2060 / P3080

2000w Laser Tube Cutting Machine (metal cutting wall thickness ability)

|

Material |

Cutting Limit |

Clean Cut |

|

Carbon steel |

16mm |

14mm |

|

Stainless steel |

8mm |

6mm |

|

Aluminum |

6mm |

5mm |

|

Brass |

6mm |

5mm |

|

Copper |

4mm |

3mm |

|

Galvanized steel |

6mm |

5mm |

3000w Laser Tube Cutting Machine (metal cutting wall thickness ability)

|

Material |

Cutting Limit |

Clean Cut |

|

Carbon steel |

22mm |

20mm |

|

Stainless steel |

12mm |

10mm |

|

Aluminum |

10mm |

8mm |

|

Brass |

8mm |

8mm |

|

Copper |

6mm |

5mm |

|

Galvanized steel |

8mm |

6mm |

Tube Laser Cutting Machine Features

P2060 / P3080 tube laser cutting machine produces high quality parts in a variety of shapes and sizes. By using its fiber laser cutting technology, multiple processes can be combined into one machine. Since most parts require multiple processes, such as traditional sawing, drilling, machining, punching and engraving, P2060 / P3080 tube fiber laser cutting machine can perform all of these processes on a single machine.

The laser tube cutting machine is equipped with a manual loader that presents the tube to the operator who must then place the tube into the machine and manually tighten the chuck. Combining all these processes into one machine saves time and cost when processing tubes in large batches yet the machines versatility allows the user to easily make prototypes or small batch production.

This tube laser cutter also utilizes high speed servos for quick and precise positioning which decreases the time for non-value added movements. These High speed servos in conjunction with the powerful fiber laser can decrease part cutting times and increase production allowing for a higher return on investment for the end user.

This laser tube cutter is also equipped with a full enclosure to ensure the operator is safe while the machine is active.

GOLDEN LASER will provide full service and support for our laser machines, including a full stock of spare parts and components to ensure our customers receive replacement parts quickly and effectively.

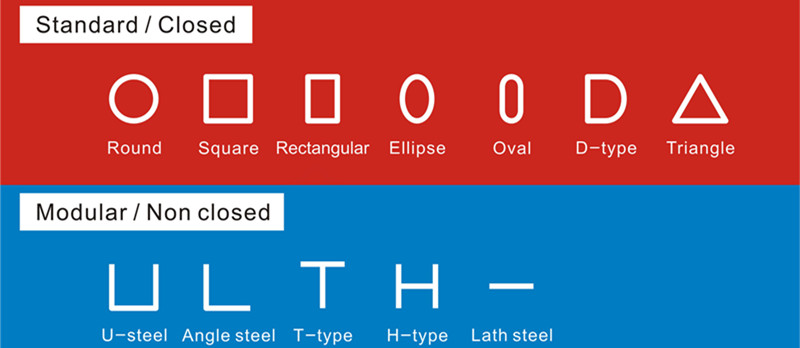

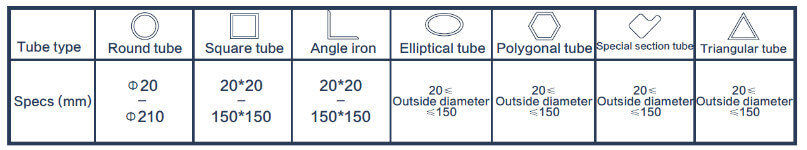

Applicable Types Of Tubes

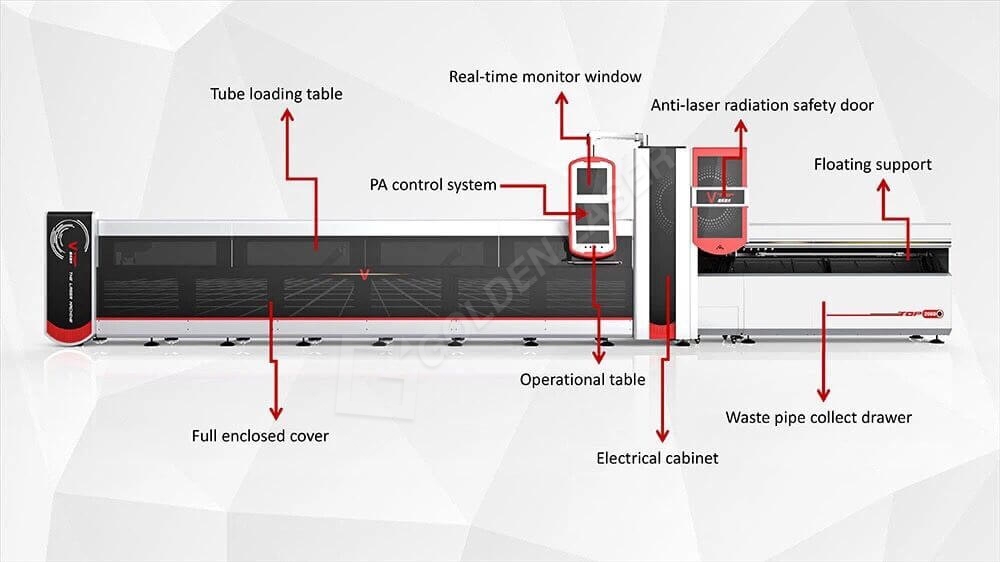

Machine Details

4000w Fully Automatic Fiber Laser Pipe Cutting Machine P3080A

Material & Industry Application

Applicable Materials

Stainless steel, carbon steel, aluminum, brass, copper, alloy steel and galvanized steel etc.

Applicable Industry

Metal furniture, medical device, fitness equipment, sports equipment, oil exploration, display shelf, agriculture machinery, bridge supporting, steel rail rack, steel structure,fire control and pipe processing etc.

Applicable Types Of Tubes Cutting

Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option)

Machine Technical Parameters

Related products

-

P1660B

Standard Fiber Laser Tube Cutting Machine P1660B -

GF-2040T / GF-2060T

3000w Dual Function Fiber Laser Metal Sheet And Tube Cutting Machine -

metal laser cutter machine

metal laser cutter machine