Contact us for a quote!

We'd like to supply a suitable and useful metal cutting solution for your reference.

Win 10 System.

Cypcut and Hypcut Beckhoff System for Choice.

Small Size with Powerful Connection Ability.

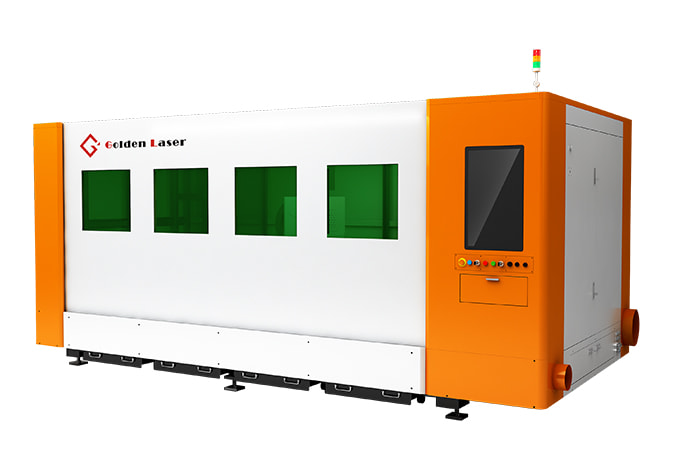

One button to open the door

Lifting design saves the operation space

When the machine door opens, the working table automatically slides out

Easy to upload the sheet metal and download the finished metal parts.

Independent laser source storage design... easy to maintenance.

The circuit and operating table are integrated into the laser cutting machine, and the industrial air conditioner stabilizes the processing temperature in production.

Based on the configuration of intelligent CNC... control system and software, it can realize efficient transformation from drawing to cutting during processing.

It can handle different materials and different process requirements with ease.

Blowing and suction type smoke removal... limited the smoke during the cutting easy to check the cutting result from the window, reduce the broken of the protect lens.

Dispose of waste on demand... The convenient pull-out design makes manual handling easier and more efficient.

Cypcut, Hypcut and Beckhoff Controller for choice to meet your different cutting demand.

Automatic nozzle clean function reduce the change of the nozzle time and ensure the good cutting result.

The lifting door and the electric slider-out drawer work table make metal processing easier.

Floor Space 4.8*2.3

Contact us for a quote!

We'd like to supply a suitable and useful metal cutting solution for your reference.

Sheet metalworking, hardware, kitchenware, electronics, automotive parts, advertising, craft, lighting, decoration, and small home businesses, etc.

Metal Welding is especially suitable for carbon steel, stainless steel, alloy, aluminum, galvanized steel, titanium, brass, copper, and other types of metal sheets.

| Laser power | 1500W to 6000W |

| Laser source | IPG / Raycus / Max fiber laser generator |

| Laser generator working mode | Continuous/Modulation |

| Beam mode | Multimode |

| Cutting area (L * W) | 3m X 1.5m |

| X-axis travel | 3050mm |

| Y-axis travel | 1520mm |

| CNC system | FSCUT controller /Beckhoff |

| Power supply | AC380V±5% 50/60Hz (3 phase) |

| Total Power consumption | Depend on the laser source |

| Position accuracy (X, Y and Z axis) | ±0.05mm |

| Repeat position accuracy (X, Y and Z axis) | ±0.03mm |

| Maximum position speed of X and Y axis | 60m/min |

| Max load of the working table | 550kg<6000W |

| Auxiliary gas system | Dual-pressure gas route of 3 kinds of gas sources |

| Format supported | AI, BMP, PLT, DXF, DST, etc. |

| Floor space | 5.8*2.3m |