Carbon Steel Tube Fiber Laser Cutting Machine P30120 Technical Parameters

| Model number | P30120 | ||

| Laser power | 1000w / 1500w / 2000w / 2500w / 3000w / 4000w | ||

| Laser source | IPG / nLight fiber laser resonator | ||

| Tube length | 12000mm | ||

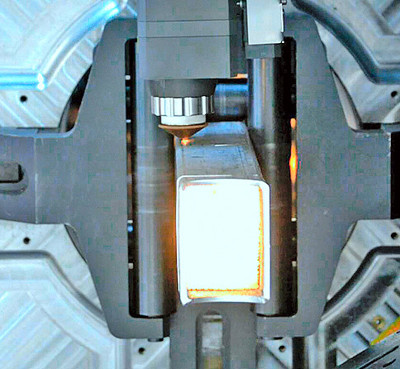

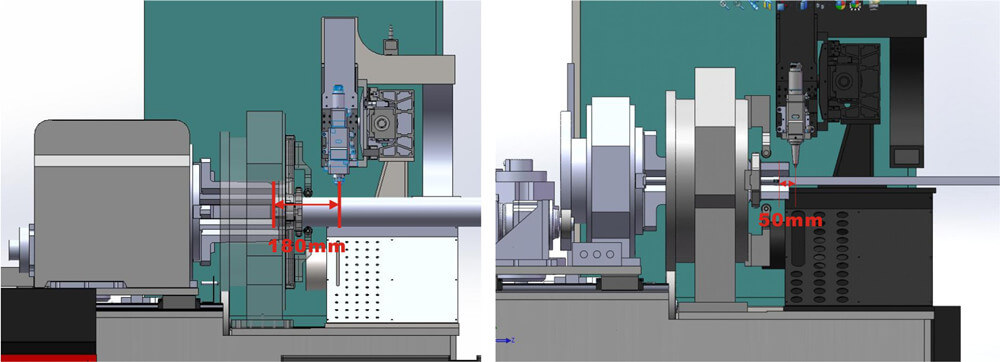

| Tube diameter | 20mm-300mm | ||

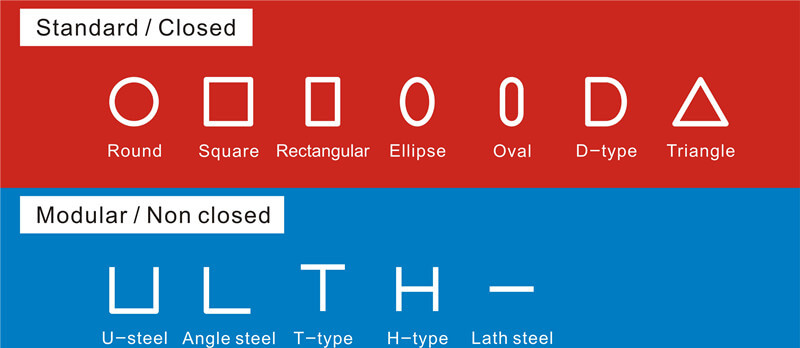

| Tube type | Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) | ||

| Repeat position accuracy | ± 0.03mm | ||

| Position accuracy | ± 0.05mm | ||

| Position speed | Max 90m/min | ||

| Chuck rotate speed | Max 105r/min | ||

| Acceleration | 1.2g | ||

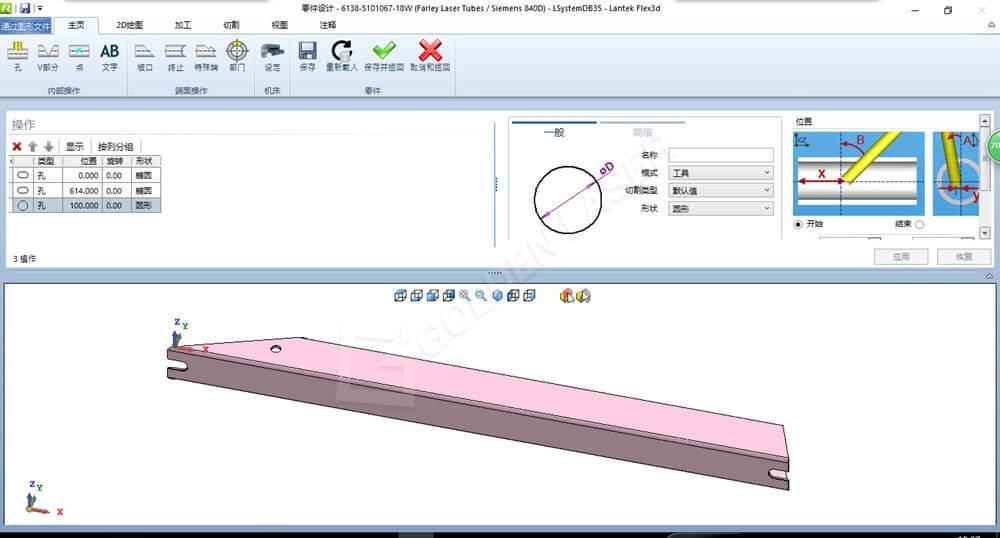

| Graphic format | Solidworks, Pro/e, UG, IGS | ||

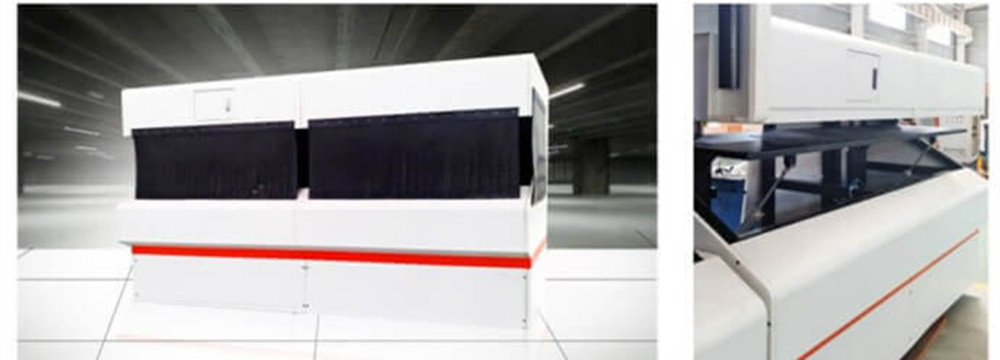

| Bundle size | 800mm*800mm*6000mm | ||

| Bundle weight | Max 2500kg | ||

| Other Related Professional Pipe Laser Cutting Machine With Automatic Bundle Loader | |||

| Model number | P2060A | P3080A | P30120A |

| Pipe processing length | 6m | 8m | 12m |

| Pipe processing diameter | Φ20mm-200mm | Φ20mm-300mm | Φ20mm-300mm |

| Applicable types of pipes | Round, square, rectangular, oval, OB-type, C-type, D-type,triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) | ||

| Laser source | IPG/N-light fiber laser resonator | ||

| Laser power | 700W/1000W/1200W/2000W/2500W/3000W/4000W | ||