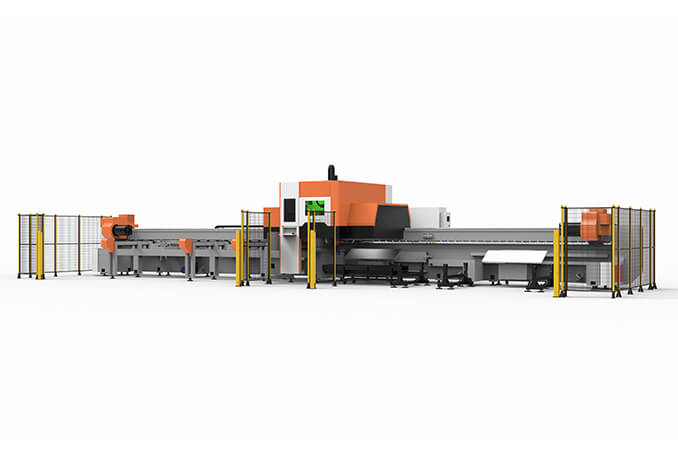

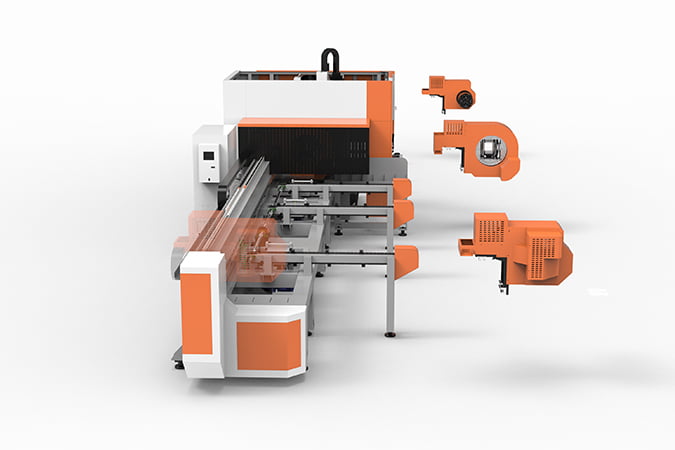

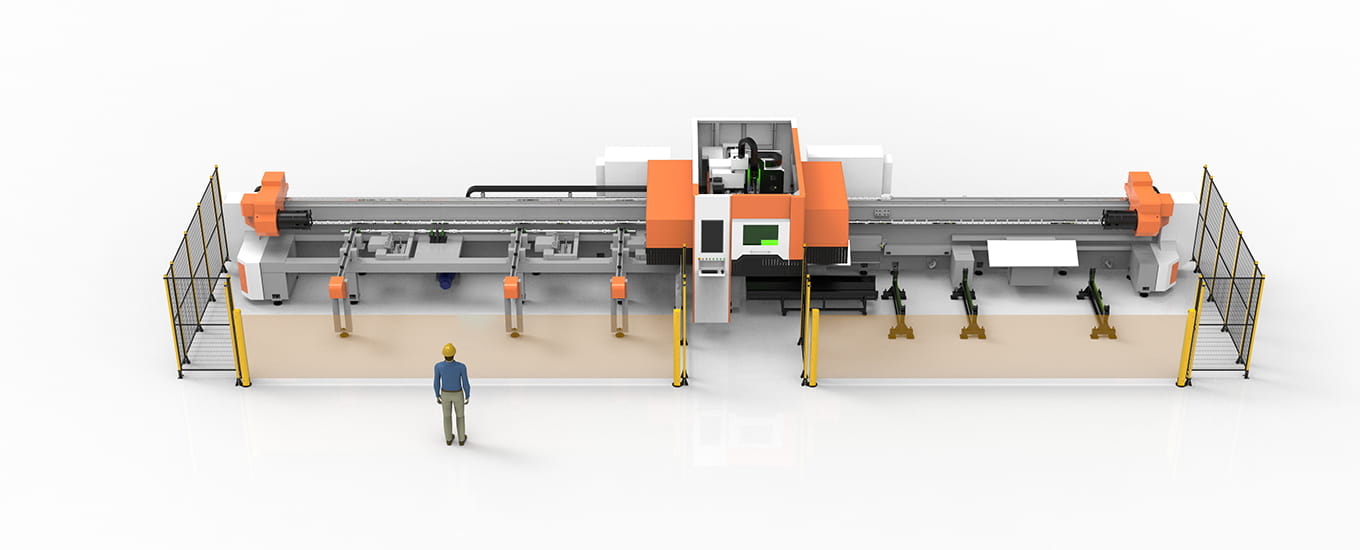

New Mega3-D Tube Laser Cutter Technical Parameters

| Model number | Meag3-3D (2026) | ||

| Laser power | 4000watt; 6000watt; 8000watt; 12000watt; | ||

| Laser source | IPG / Raycus / Max fiber laser resonator | ||

| Tube length | 6000mm | ||

| Single Tube Weight | 1ton | ||

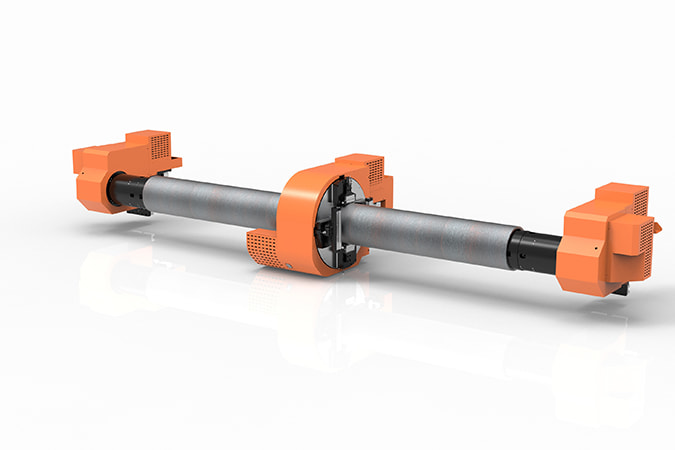

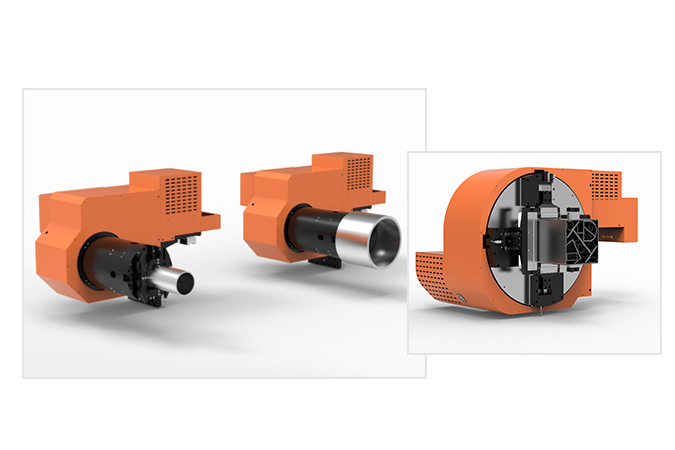

| Tube diameter | Round Tube: Ø20mm-Ø360mm /Ø20mm-Ø450mm /Ø20mm-Ø520mm Ø20mm-Ø650mmSquare Tube:200*20mm -360*360mm/ | ||

| Tube type | Round, square, rectangular, oval, OB-type, C-type, D-type, triangle, etc (standard); Angle steel, channel steel, H-shape steel, L-shape steel, etc (option) |

||

| Position accuracy | ± 0.05mm/m | ||

| Position speed | Max 60m/min | ||

| Chuck rotation speed | Max 60r/min | ||

| Acceleration | 0.5g | ||

| Controller | FSCUT with TubesT | ||

| Graphic format | Solidworks, Pro/e, UG, IGS | ||

| Bundle size | Length: 3500mm to 6000mm, | ||

| Bundle weight | Max 3 Tons |