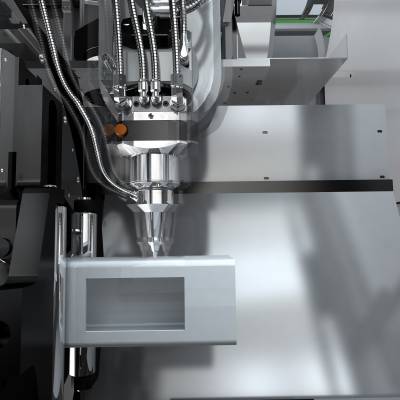

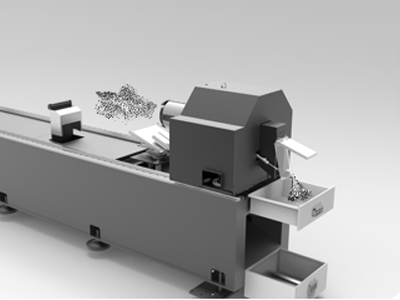

Professional Self-centering Pneumatic Chuck Clamping System

The chuck is made of high-bearing steel material, with high sealing performance and good dynamic performance.

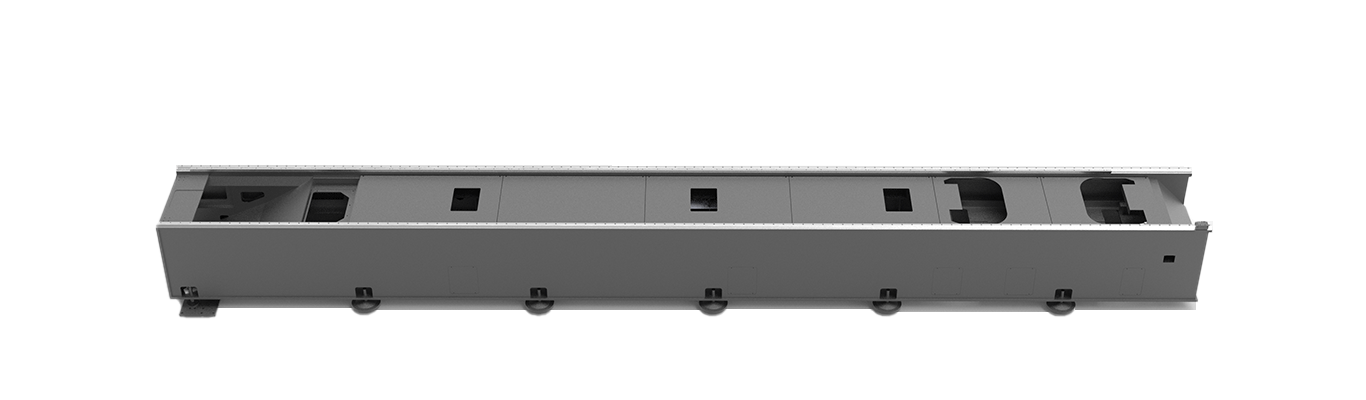

The intermediate chuck is innovatively embedded in a casting frame and integrated with the main body of the machine structure.

No need to adjust the jaw position for full stroke clamping.

The maximum clamping force of the chuck is up to 300kg, which is 25% higher than the previous generation of chucks.

The maximum speed can reach 130r/min.