Full Enclosed Strurcture

1. The real Full enclosed structure design completely pretents all visible laser in the equipment working area inside, to reduce laser radiation damaget, and provide safty protection for operator’s processing environment;

2. During metal laser cutting process , it produces heavily dust smoke. With such full closed structure , it ensures good segregation all dust smoke from outside . Concerning about the principle of hot smoke dust dynamic flow ,we adopt roof multiple distributed pump design instead of traditionalbottom pump design. Meanwhile , we have upgraded big powerful fans to work , aiming at minimize the dust pollution , to keep clean and friendly working environment and protect the health of the operator from long run.

Control Table

1. Abandon the traditional equipment shell embedded operation platform, it uses external rotary control platform, retain the integrity of the overall appearance of the equipment, cater to the high-end CNC equipment industrial design standards.

2. The console rotates in three dimensions at a 270 degree Angle to support multi-dimensional operation

3. Monitoring window, operation interface, high-end numerical control panel, wireless mouse and keyboard are integrated into the operation table. Only one same interface can be realized switching the machine on and off , or restart in standby maintenance state .

4. The device is equipped with high-definition surveillance camera, real-time dynamic display of the whole process of laser cutting.Equipment operation and machine operation status monitoring can be considered at the same time.

5. The device is equipped with high-definition surveillance camera, real-time dynamic display of the whole process of laser cutting.Equipment operation and machine operation status monitoring can be considered at the same time.

Software

Reducer

Golden Vtop adopts nLIGHT laser Generator-High reflective metal cutting capacity

The nLIGHT laser has advantage in high-reflective metal material cutting performance, to achieve normal processing of aluminum, brass, copper, gold and silver etc, while it has outstanding cutting performance of conventional carbon steel and stainless steel as well.

NLIGHT laser – prevents condensation

With NEMA 12 standard sealing design, all modules have CDA gas purification interface. Built-in humidity sensor and internal locking device, which can be easy to integrate into the equipment.The continuous input of low pressure air inside the laser which can ensure that the laser is always in dry environment. Decreasing the effect of external environment temperature and humidity on the laser to minimum. Meanwhile , he internallaser source is filled with air ,to form pressure gradually, then to form shielding layer of laser external barrier , which aviod dust going inside , it can keep the laser inside cleaning. These such innovative designs of Nlight source have greatly prolong the lifetime of laser.Thus, the laser can be separately equipped with air conditioner, to maintain its constant stbale temperature and prevent condensation efficiently . Therefore, nLIGHT laser has this unique advantage in strong tolerance to poor environment condition.

NLIGHT laser – modules are not easily to damage

NLIGHT laser – modules are not easily to damage

1. According to the tracking of customer equipment usage in recent years, the statistical analysis of laser failure rate data shows that the failure rate of nLIGHT laser is much lower than other brands, the module damage rate is almost zero, and remain the long-term stable running performance. It has got a lot of new and old customers the favor and trust, , eliminating the doubts of the nLIGHT laser in the initial stage, and stickly to choose the nLIGHT brand after using it.

2. And for some other laser brands .after using a period of time, especially after beyond warranty time, The internal laser moudle damage rate is very high and often , caused by ondensation or some other problems. To make replacement of new module price is very high, cycle time is long.the customer sufferred an inreasing loss for such issue.

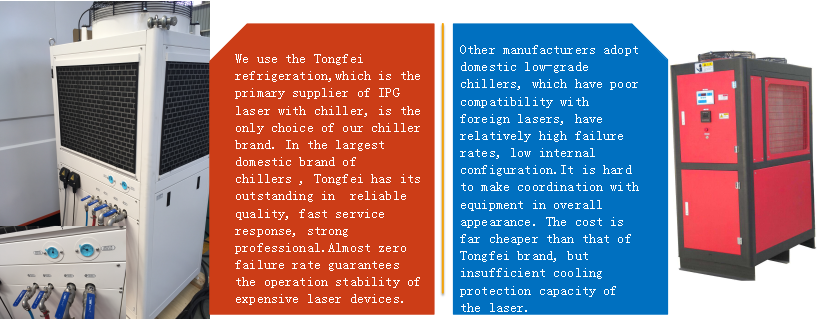

Water Chiller

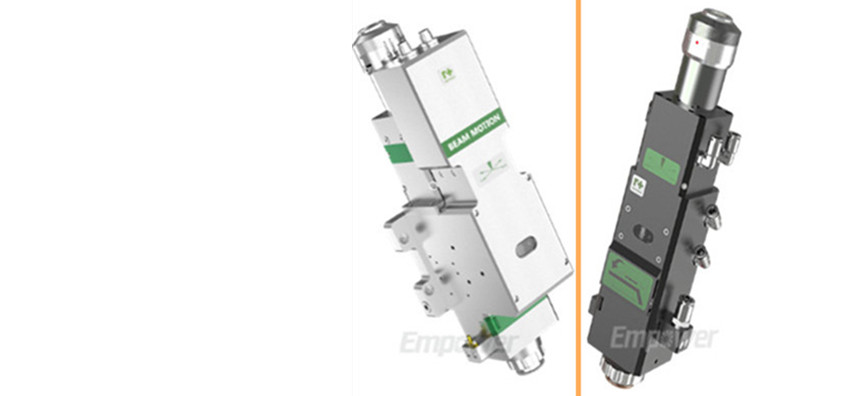

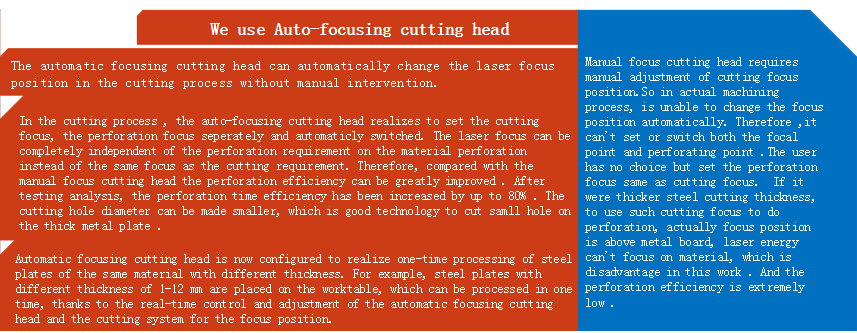

Auto-focusing cutting head

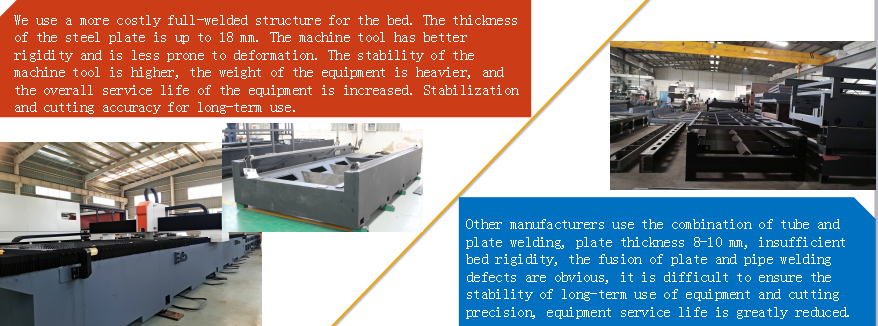

Welded Machine Body

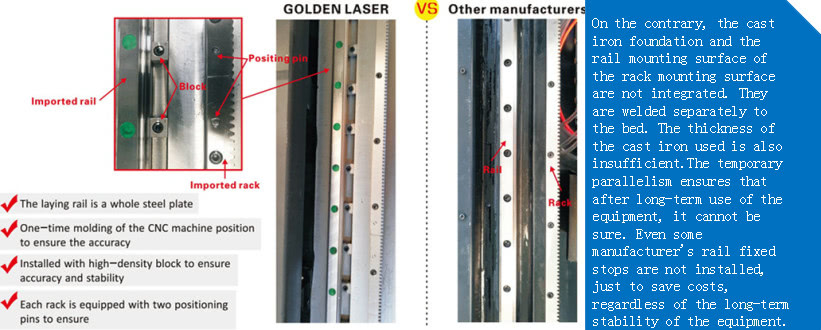

Rack guide rail mounting surface

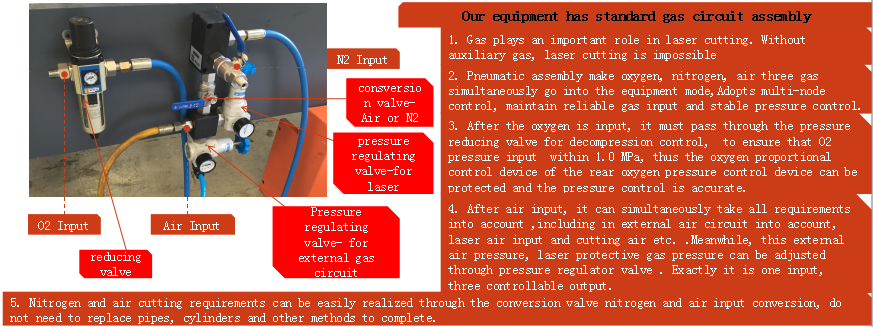

Gas Circuit

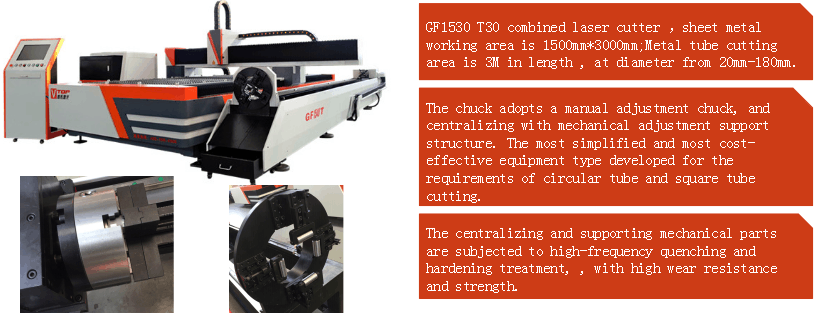

Metal Sheet And Tube Integrated Laser Cutting Machine -3 m tube cutting

GF-T Series

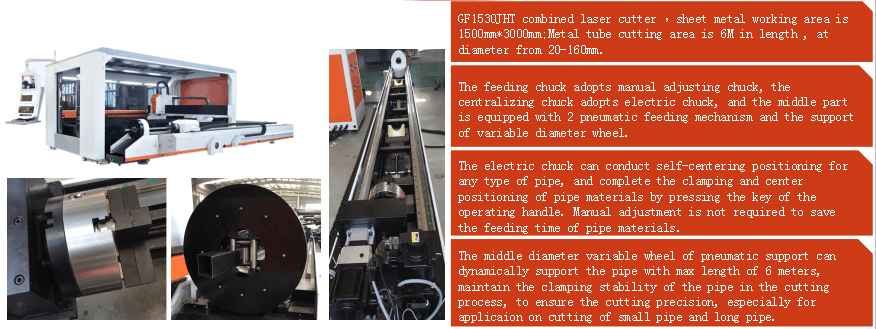

GF-1530JHT

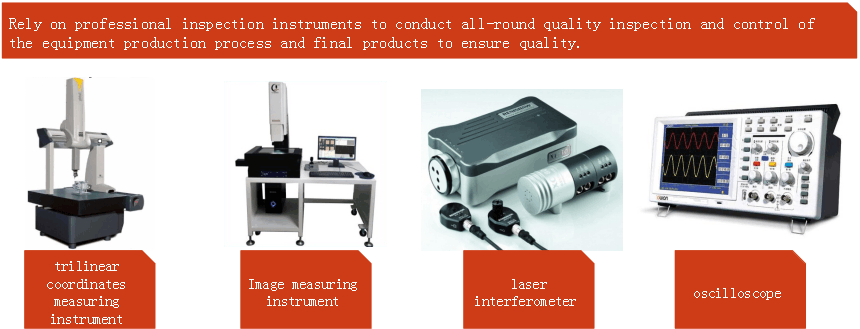

Equipment QC inspection hardware

Machine inspection reports

GF-JH Series Machine Demo Video

GF-JHT Series Machine Demo Video