In the increasingly competitive metal processing industry, efficiency and quality remain the core competencies pursued by enterprises. For the manufacturing of customized, multi-angle tubular structural components like stair railings, the traditional "measure-draw-program-cut" process is time-consuming and error-prone, severely limiting production speed.

Your laser tube cutting machine is already an industry powerhouse, recognized for its superior cutting precision and speed. Now, by integrating the revolutionary "Drawing-Free Production and Processing Function for Stair Railings," it is bringing a complete efficiency overhaul to stair railing manufacturing.

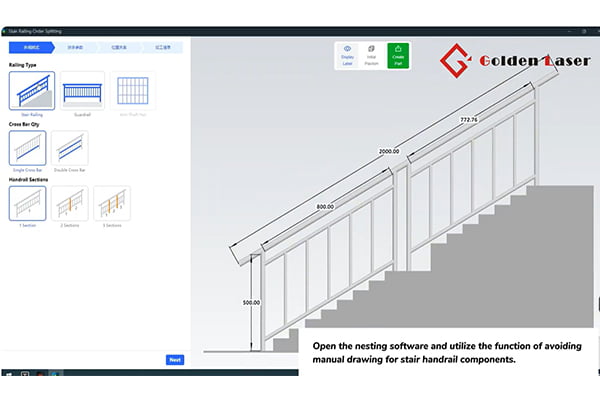

Eliminate Tedious Drawing for Ultra-High Efficiency Production

In the traditional stair railing production workflow, manual drawing and CAD programming are the most time-consuming steps. The varying slopes, angles, and dimensions of different staircases require experienced engineers to spend a significant amount of time on precise measurement and drawing. A slight mistake can lead to material waste or costly rework.

The "Drawing-Free" function completely subverts this model. It embeds complex geometric calculations and programming logic directly into the system. Users only need to complete three simple steps:

-

Measure Key On-Site Parameters: Only basic data such as stair slope, total handrail length, and material specifications (e.g., wall thickness, diameter/side length) are required.

-

One-Click Data Input: Input the measured key values into the system's concise operating interface.

-

System Automatically Generates Cutting Path: The system instantly calculates the cutting angle, length, hole position, and shape for all required tubes, and generates both a 3D model and the laser cutting program.

This innovation drastically reduces the time spent on drafting and programming from several hours or even days to just a few minutes. The operational barrier is significantly lowered, allowing even novice operators to quickly get started, notably increasing equipment utilization and overall production efficiency.

Enhanced Precision, Building Flawless Quality

The increase in speed is achieved without sacrificing quality. On the contrary, the "Drawing-Free" function utilizes digital and standardized calculation models to minimize human error, further ensuring and improving the quality of the finished stair railings.

-

Ultimate Joint Precision: The system uses accurate mathematical models to calculate the optimal bevel angle and intersecting line for every tube connection, ensuring the parts achieve perfect alignment during assembly without the need for secondary grinding or modification.

-

Elimination of Human Error: It eliminates dimensional deviations and angle inaccuracies caused by manual drafting and programming, ensuring high consistency in the processing dimensions of all components from the source.

-

Optimized Material Utilization: The intelligent algorithm also considers nesting optimization when calculating the cutting paths, utilizing the tubular material in the most scientific way possible to achieve higher material utilization and lower production costs.

By combining your laser tube cutter with the "Drawing-Free" function, stair railing manufacturers can achieve the production goals of "high efficiency, high precision, and low cost." This is more than just an equipment upgrade; it is a deep optimization of the traditional manufacturing model, helping customers gain a competitive edge in the fierce market landscape.

Act Now: Unlock the Future of Smart Manufacturing

No matter whether customization or traditional manufacturing demands, the combination of your laser tube cutter and the "Drawing-Free" function is a powerful response to the future trend of smart manufacturing. It will help your factory achieve:

-

Double Efficiency: Drastically compresses preparatory time for rapid delivery.

-

Quality Assurance: Ensure every railing set achieves seamless, precise on-site assembly.

-

Cost Control: Reduce labor costs and material waste.

Embrace innovation and seize the future.