Welcome to Golden Laser

Find the Most Suitable Laser Tube Cutter

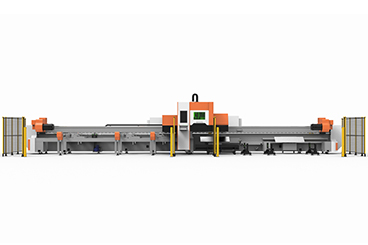

i Series

The Intelligent “i” series is an intelligent, digital and automated all-round high-end laser pipe cutting machine.

2D and 3D Laser Cutting Head | Automated advanced tube loader | MES system compatible

Model No.: i20A-3D / i25A-3D

Germany PA controller

Diameter: 200-250mm

3D Laser Head for Tube Beveling

Model No.: i20 / i25A /i35 /i35A

Germany PA controller

Diameter: 200mm /250mm /350mm

2D Laser head

Mega Series

MEGA series is 3 and 4 chucks laser tube cutting machine

developed for ultra-large (350mm to 650mm diameter tube), heavy, and long pipes and profiles cutting.

Flexible Configuration | Side Hanging Structure | Zero Tail Waste Tube Cutting

S Series

Smart "S" series ultra-small tube laser cutting machine

Especially designed for small tubes cutting.

intelligent control system, small tube clamping configuration, fully automated feeding, cutting, and rewinding to achieve high-speed and high-precision cutting of small tubes.

Compact design tube loader | High degree of automation | high speed and great accuracy

L Series

Side-mounted Model Small tube laser cutting machine

Improve whole production efficiency.

Small tube clamping setup with fully automated feeding, cutting, and collection. This achieves fast and precise cutting of small tubes..

Compact design tube loader | High degree of automation | high speed

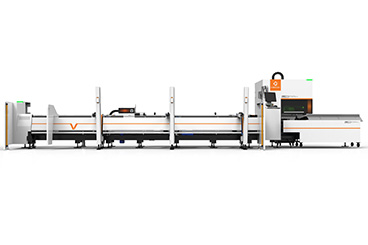

F Series

EcoFlex “F” is an economical laser pipe cutting machine.

Durable and widely applicable

Wide range of processing | Automated and semi-automatic tube loader | Easy to operate

Model No.: F16A / F20A / F20A-3D

China FSCUT controller or Germany PA for choice

With Loader A2 | 3D Laser Head Optional

HP Series

H Beam laser cutting machine

Especially designed for H beam, I beam cutting, widely used for the structure and bridge industry.

Bridge Structure Design | 3D Laser Head | Customize Length

Why Golden Laser

REQUEST A QUOTE FOR MORE DETAILS

All You Need To Know About Laser Tube Cutting Machine in 2025

The laser tube cutting machine is one type of a fiber laser cutting machine that only cuts different metal materials tubes and pipes (stainless steel, carbon steel, brass, Aluminum Profile), different from other pipe cutting tools, it is a no-touch high precise cutting method, it is no distortion during the production.

Customized Chuck Meet Different Tube and Profile Diameter and Weight to Ensure Great Laser Cutting Result

Easy to cut complicated designs on the tube and high accuracy perforation by a laser tube cutter.

Easy to change your production design method in an intelligent CNC laser controller.

Vision function for tube cutting application

Tube inside slag removal solution

Pipe cutting sample tower with no welding or adhesion

What is the Advantage of Laser Tube Cutting Machines over traditional pipe cutting methods for metal tubes?

1. Suit Many Shaped Pipes

Round, Square, Rectangle, and other special-shaped pipes, Channel Steel, I Beam, Profile, and so on.

2. High-Efficiency Perforation

High accuracy of about 0.01mm(cutting result), easy to cut any complicated design, especially perforation in pipe cutting job.

3. No Pressure on the Metal Surface

Laser cutting is a high-temperature, no-touch cutting method; it won't press the materials, and no distortion during production.

4. Welding Pipe Recognize

Recognize and avoid welding lines to reduce breaking during laser cutting.

Laser Tube Cutting Machine Manufacturing

Main Parts

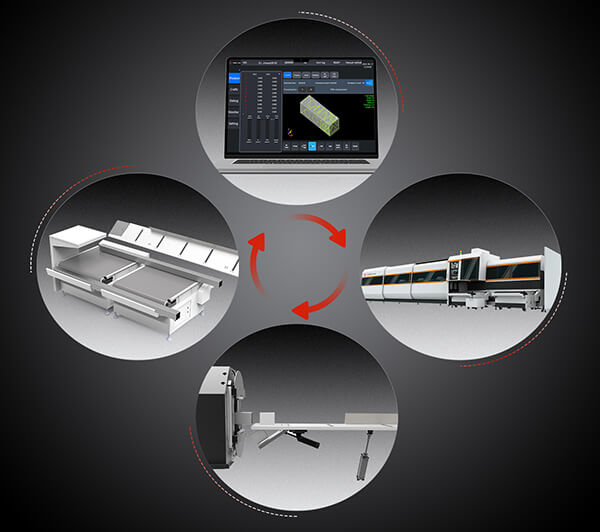

How Does a Laser Tube Cutting Machine Work?

_

The mechanism of the laser tube cutting machine is primarily like this.

1. Input the tube type into the laser tube Nesting (Lanteck) software,

Set the right cutting design parameter according to the metal thickness and type of steel, mild steel, stainless steel, Al, Brass, and so on.

2. Export the file into the laser tube cutting machine controller,

All the standard Shape of metal tubes will show them 3D shape on the operation screen, you can double-check the design more clearly

3. Loading the right tube onto the laser tube cutting machine

With an automatic loading system, you needn't worry about the wrong tube mixed together with a bundle of tubes, it will automatically measure or alarm if you haven't set the mix cutting job on the cutting program.

4. Start to cut and collect the finished metal tube.

Be sure the water chiller and air compressor are open before pressing the "start" button, the tailer of the tube will follow down to the waste collection box under the bottom of the machine, and the finished parts will send to the conveyor table for the collocation box.

Why Choose Golden Laser Steel Laser Tube Cutting Machine?

Considerations When I want to Buy a Laser Tube Cutting Machine

1. What's the Main Thickness Do You Need to Cut?

It is important to choose the right laser power steel laser cutting machine because the different laser power the price will very different.

Choose according to the max thickness, the investment will easily go over your budget.

2. Whether I need to cut the Shaped profile of the Metal Tubes?

For regular shape metal tube, it is easy to cut, like round, square, and rectangle.

If need to cut shaped pipes, like Channel Steel, I beam, C type pipes is better to check with expert for double ensure whether can by cut.

3. Need to Connect With ERP System or Not?

Consider your factory situation, and choosing a suitable laser controller will be a good choice.

If needn't to connect ERP systems with other milling machines, China controller FSCUT will be a good choice, friendly interface and easy to operate.

Golden Laser Germany PA controller tube laser cutting machine with Spanish Lantek professional tube nesting software will better suit ERP and MES management. and professional operater

4. Understanding of the Industry Application Demand

A useful laser cutting machine is designed according to detailed customer demands. Many functions are customized after deeply studying the customer's production needs.

This meets the potential demand and simplifies and increases the efficiency of the production line.

Golden Laser has more than 20 years of Strong R&D ability, giving you better support in finding a steel laser tube cutting machine.

5. Machine Quality and Factory Experience

To supply a good quality steel tube laser cutting machine, one needs good experience in light route, electric route, water route, and 3D laser cutting technology. It does not just compose them together.

Golden Laser has 20 years of experience in producing good quality and steady fiber laser tube cutting machines, rich experience with metal tube laser cutting machines, on-time after-service team to ensure a good user experience of the steel laser tube cutting machine.

6. After-Sale Serviceability

Golden Laser exports the laser cutting machine to over 120 different countries and cities.

You can check the quality of our machine locally and enjoy door-to-door on time after service through our agent or the factory directly.

We also have a Euro Service Center in the Netherlands for expert installation support and long-term warranty

We'd Like to Work With You

Please send us a message if you have any questions or requests on steel laser cutting machines.