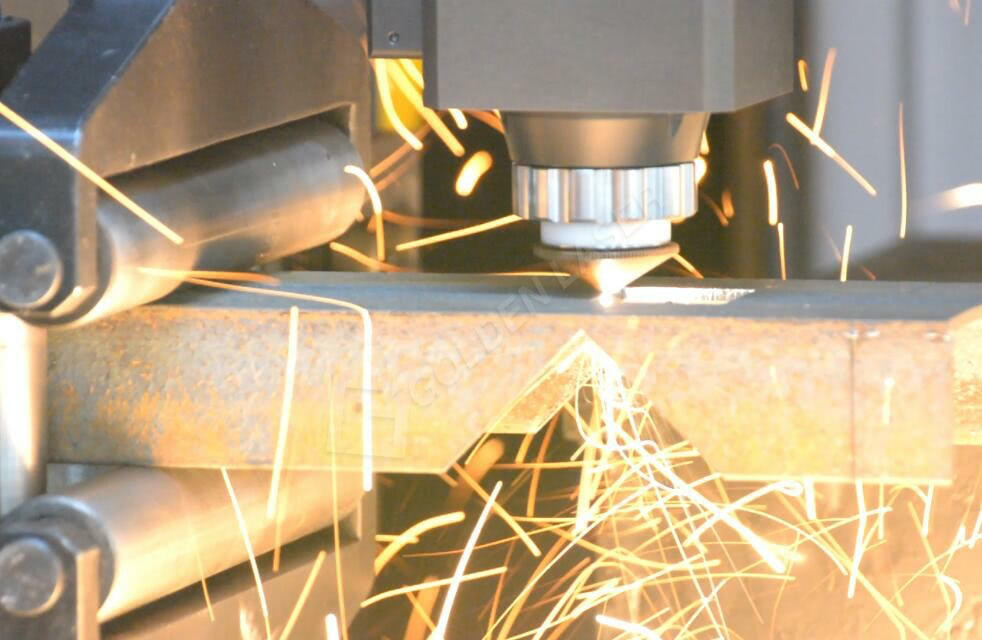

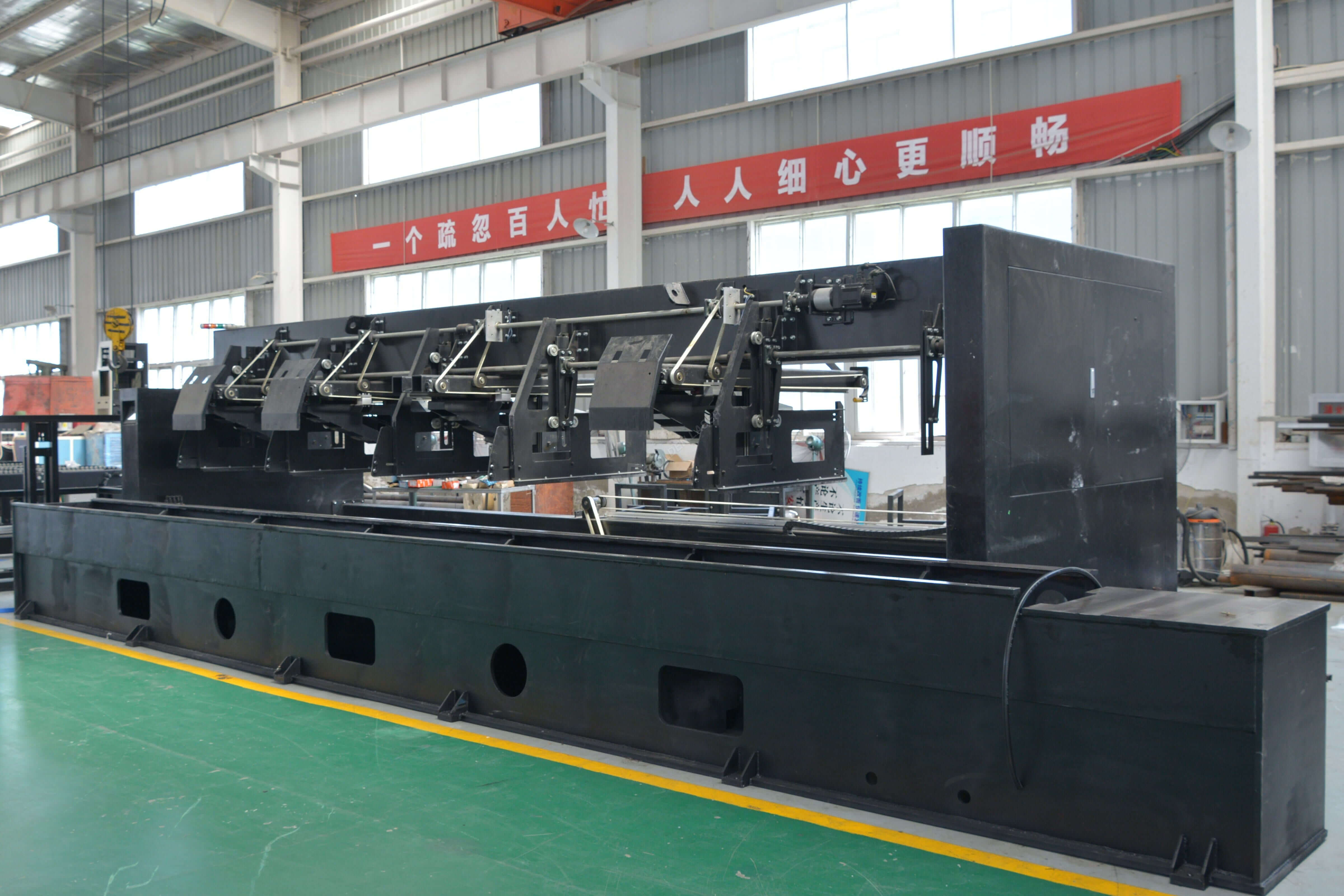

Golden Laser pipe laser cutting machine P series adopts most sophisticated fiber laser resonator Nlight or IPG from USA, and imported fiber laser cutting head from Switzerlands Raytools, combining self designed gantry type CNC machine bed and high strength welding body, the machine is of good performance.

After high temperature annealing and precision machining by large CNC milling machine, it has good rigidity and stability. By adopting imported high precision spare parts, like linear guide drive, high-speed servo motor, aluminum beam, advanced heat treatment process, high strength, light weight, good rigidity, the machine has been very popular in the market home or broad.

1.The minimum waste pipe length is within 20mm, which pushes the limits.

2.The CNC pipe laser cutting machine is easy to learn and operate, one operator can control two machines in one time, and women can also operate it. With powerful control fuction, the machine is easy to start and stop; after pipe cutting process is finished, the machine will stop automatically, and the finished pipes are in the collection box.

3.Twice vibration aging and annealing ensure the machine with good stability and anti-shake, so the machine accuracy will last for 15 years.

4. The guider installation all adopts high end equipment like measuring instruments and laser interferometers to ensure 55mm thickness installation datum plane.

5. Automatic pipe feeding system makes large quantities of pipe feeding and cutting automatically, and the feeding is accurate and fast. Highly automated, less error-prone and labor-saving. The automatic feeding system supports 800*800mm bunch pipes, the maximum loading weight is 25kg per meter.

6. The guid rail is equpped with automatic lubrication system, so it can ensure long term smooth operation without stopping.

7. It can automatically change the lead line and avoid collision according to different holes, and automatically calibrate the vector to prevent collision, these functions are especially effective for special-shaped tubes. The calibration algorithm will also vary depending on different tubes.

8. It can parameterize the parts to drawing the design in batch through EXCEL format, which is convenient and saves a lot of drawing time.

9. We will exchange some parts, key components or key technologies to achieve the pipe laser cutting machine upgrading, and make the production capacity, performance, efficiency etc. of original machine or production line updated. Thus this upgrading extends the pipe laser cutter’s serive life, saves raw materials and labor, reduces costs.

10. Good cutting rigidity and cutting speed, the cutting spped reaches to 90 meters per minute, and the cutting angle is changeable. With high automation, it saves a lot of work time. The equipment is easy to maintain which increases its service life.

11. Since the diameter-varied supporting has strong clamping force, so the pipe will not swing to cause inaccurate accuracy. And the guide rail uses automatic lubrication device so there is no change of machine stopping.

12. The end face plate and slider groove internal are all dust proof, also the back chuck has dust extraction device, all these can enusre the machine stable performance.

13. The machine is suitable for cutting high reflective metal materials like copper, aluminum, galvanized pipe and others. And it supports round, square, rectangular, elliptical, triangular, pentagonal, flat, angle, channel, irregular and other types of pipe design, saving new product development time.

14. The equipment has been developed through extensive industry applications and numerous installation experiences. Whether it is the material loading or cutting, the accurate measurement value of each pipe is used to automatically calculate the optimal material utilization and save the material to the maximum extent. The waste naturally decreases.

15. No dust and no noise, it is specially designed for environmental protection industry.

16. It owns the auto edge searching function, if the pipe is biased, the cutting head can automatically identify and complement the bias.

17. Pipes within the set tolerance range can be detected. If the pipe length is not suitable, it will alarm.

18. It can realize the precise cutting of all kinds of complex design which can not be realized by aw blade moulds such as hole cutting, cutting off, cutting difficult pattern, intersecting lines etc.

19. For thick pipe it has automatic focus adjusting function, which can increase the prodction rate without hole blast; improving cutting efficiency and reduce cutting time; the exchanging of thin pipe and thick pipe can automatically obtain the corresponding parameters from the process library.

20. For the P series pipe laser cutting machine we have three models for your choice P2060, P3080 and P30120, so it can process pipe length 6000m, 8000mm, 12000mm.

21. The pipe outer diameter should be within 320mm or the diagonal within 320mm.

22. The machine can cut arc, groove, oblique.

23. The chuck automatically adjusts the clamping force according to the tube type, diameter and wall thickness etc. The thin tube will not deformed and the large tube is clamped tightly.

24. The machine control software has strong reading ability and intelligent nesting; it can process the 3D design according to Golden Laser CAD-CAM system.

25. Imported high-quality components, the pneumatic components used in the machine are adopting imported brands, thus it can ensure the machine system is stable and meets the export standards.

26. Imported high-quality components, the pneumatic compone

nts used in the machine are adopting imported brands, thus it can ensure the machine system is stable and meets the export standards.

27.The cutting precision is ±0.03mm.

28.The machine is able to cut buckle and process groove.

29.The machine cutting quality is high. The pipe will not deformed by heat, and the inner wall is smooth after cutting, the surface is smooth and no need of secondary grinding, zero burr without shrinkage and convenient for welding.

30.The machine can cut 30°,45° or 90° angle according to customer actual using, two 45°angle can piece into 90°angle perfectly.