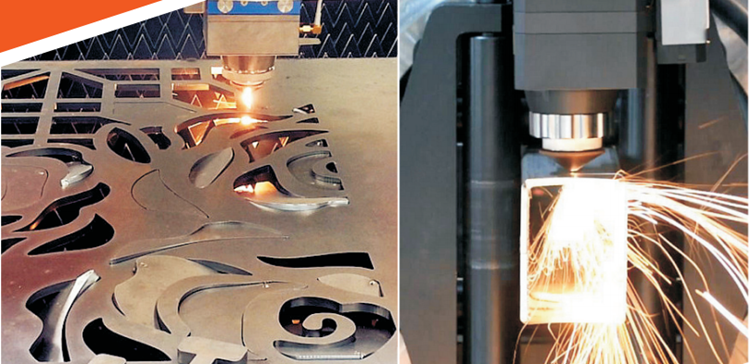

Laser manufacturing activities currently include cutting, welding, heat treating, cladding, vapor deposition, engraving, scribing, trimming, annealing, and shock hardening. Laser manufacturing processes compete both technically and economically with conventional and nonconventional manufacturing processes such as mechanical and thermal machining, arc welding, electrochemical, and electric discharge machining (EDM), abrasive water jet cutting, plasma cutting and flame cutting.

Water jet cutting is a process used to cut materials using a jet of pressurized water as high 60,000 pounds per square inch (psi). Often, the water is mixed with an abrasive like garnet that enables more materials to be cut cleanly to close tolerances, squarely and with a good edge finish. Water jets are capable of cutting many industrial materials including stainless steel, Inconel, titanium, aluminium, tool steel, ceramics, granite, and armor plate. This process generates significant noise.

The table that follows contains a comparison of metal cutting using the CO2 laser cutting process and water jet cutting process in industrial material processing.

§ Fundamental process differences

§ Typical process applications and uses

§ Initial investment and average operating costs

§ Precision of process

§ Safety considerations and operating environment

Fundamental process differences

| Subject | Co2 laser | Water jet cutting |

| Method of imparting energy | Light 10.6 m (far infrared range) | Water |

| Source of energy | Gas laser | High-pressure pump |

| How energy is transmitted | Beam guided by mirrors (flying optics); fiber-transmission not feasible for CO2 laser |

Rigid high-pressure hoses transmit the energy |

| How cut material is expelled | Gas jet, plus additional gas expels material | A high-pressure water jet expels waste material |

| Distance between nozzle and material and maximum permissable tolerance | Approximately 0.2″ 0.004″, distance sensor, regulation and Z-axis necessary | Approximately 0.12″ 0.04″, distance sensor, regulation and Z-axis necessary |

| Physical machine set-up | Laser source always located inside machine | The working area and pump can be located separately |

| Range of table sizes | 8′ x 4′ to 20′ x 6.5′ | 8′ x 4′ to 13′ x 6.5′ |

| Typical beam output at the workpiece | 1500 to 2600 Watts | 4 to 17 kilowatts (4000 bar) |

Typical process applications and uses

| Subject | Co2 laser | Water jet cutting |

| Typical process uses | Cutting, drilling, engraving, ablation, structuring, welding | Cutting, ablation, structuring |

| 3D material cutting | Difficult due to rigid beam guidance and the regulation of distance | Partially possible since residual energy behind the workpiece is destroyed |

| Materials able to be cut by the process | All metals (excluding highly reflective metals), all plastics, glass, and wood can be cut | All materials can be cut by this process |

| Material combinations | Materials with different melting points can barely be cut | Possible, but there is a danger of delamination |

| Sandwich structures with cavities | This is not possible with a CO2 laser | Limited ability |

| Cutting materials with liminted or impaired access | Rarely possible due to small distance and the large laser cutting head | Limited due to the small distance between the nozzle and the material |

| Properties of the cut material which influence processing | Absorption characteristics of material at 10.6m | Material hardness is a key factor |

| Material thickness at which cutting or processing is economical | ~0.12″ to 0.4″ depending on material | ~0.4″ to 2.0″ |

| Common applications for this process | Cutting of flat sheet steel of medium thickness for sheet metal processing | Cutting of stone, ceramics, and metals of greater thickness |

Initial investment and average operating costs

| Subject | Co2 laser | Water jet cutting |

| Initial capital investment required | $300,000 with a 20 kW pump, and a 6.5′ x 4′ table | $300,000+ |

| Parts that will wear out | Protective glass, gas nozzles, plus both dust and the particle filters |

Water jet nozzle, focusing nozzle, and all high-pressure components such as valves, hoses, and seals |

| Average energy consumption of complete cutting system | Assume a 1500 Watt CO2laser: Electrical power use: 24-40 kW Laser gas (CO2, N2, He): 2-16 l/h Cutting gas (O2, N2): 500-2000 l/h |

Assume a 20 kW pump: Electrical power use: 22-35 kW Water: 10 l/h Abrasive: 36 kg/h Disposal of cutting waste |

Precision of process

| Subject | Co2 laser | Water jet cutting |

| Minimum size of the cutting slit | 0.006″, depending on cutting speed | 0.02″ |

| Cut surface appearance | Cut surface will show a striated structure | The cut surface will appear to have been sand-blasted, depending on the cutting speed |

| Degree of cut edges to completely parallel | Good; occasionally will demonstrate conical edges | Good; there is a “tailed” effect in curves in the case of thicker materials |

| Processing tolerance | Approximately 0.002″ | Approximately 0.008″ |

| Degree of burring on the cut | Only partial burring occurs | No burring occurs |

| Thermal stress of material | Deformation, tempering and structural changes may occur in the material | No thermal stress occurs |

| Forces acting on material in direction of gas or water jet during processing | Gas pressure poses problems with thin workpieces, distance cannot be maintained |

High: thin, small parts can thus only be processed to limited degree |

Safety considerations and operating environment

| Subject | Co2 laser | Water jet cutting |

| Personal safetyequipment requirements | Laser protection safety glasses are not absolutely necessary | Protective safety glasses, ear protection, and protection against contact with high pressure water jet are needed |

| Production of smoke and dust during processing | Does occur; plastics and some metal alloys may produce toxic gases | Not applicable for water jet cutting |

| Noise pollution and danger | Very low | Unusually high |

| Machine cleaning requirements due to process mess | Low clean up | High clean up |

| Cutting waste produced by the process | Cutting waste is mainly in the form of dust requiring vacuum extraction and filtering | Large quantities of cutting waste occur due to mixing water with abrasives |