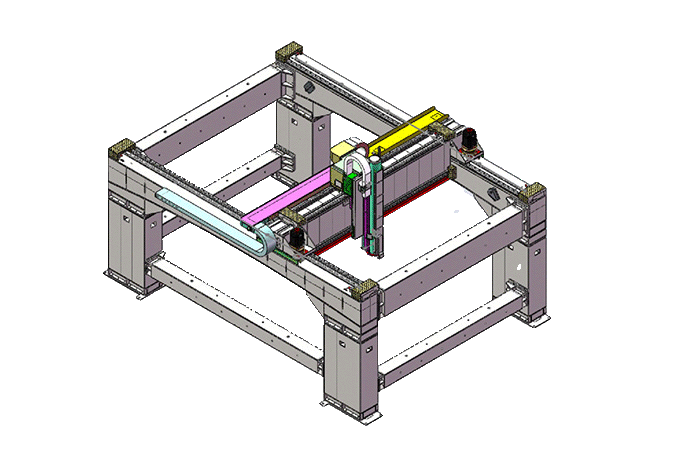

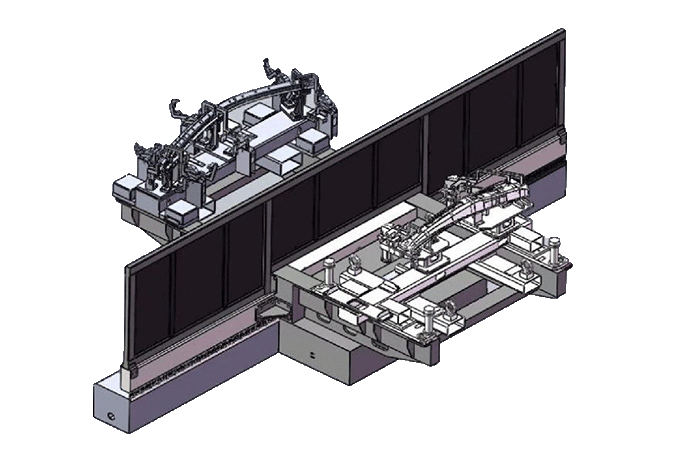

Cell 4000 5-Axis Laser Cutting Machine Parameters

|

Number |

Parameter name |

Numeric value |

|

1 |

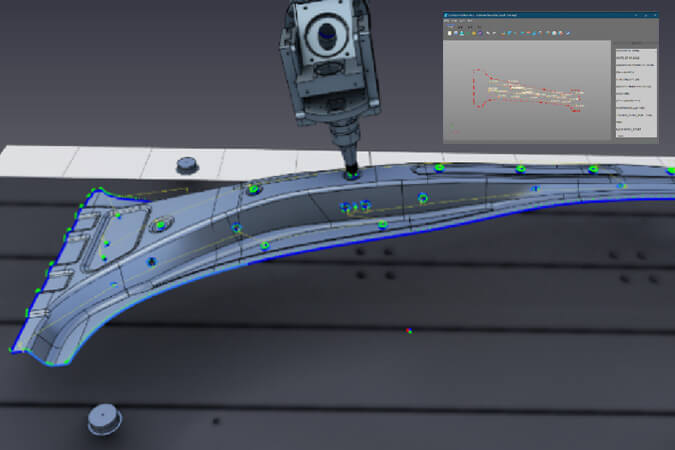

Maximum machining range of flat workpiece |

4000mm×2100mm |

|

2 |

Maximum machining range of three-dimensional workpiece |

3400mm×1500mm |

|

3 |

X axis travel |

4000mm |

|

4 |

Y axis travel |

2100mm |

|

5 |

Z axis travel |

680mm |

|

6 |

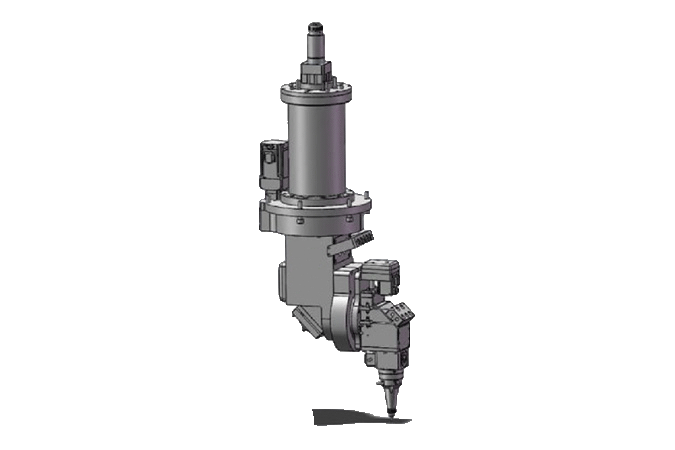

C axis stroke |

N*360° |

|

7 |

Axis A travel |

±135° |

|

8 |

U axis travel |

±9mm |

|

9 |

X, Y and Z axis positioning accuracy |

±0.04mm |

|

10 |

X, Y and Z axis repeated positioning accuracy |

±0.03mm |

|

11 |

C, A axis positioning accuracy |

±0.015° |

|

12 |

C, A axis repeated positioning accuracy |

0.01° |

|

13 |

Maximum speed of X, Y and Z axes |

80m/min |

|

14 |

maximum speed of axis C, A |

90r/min |

|

15 |

Maximum angular acceleration of axis C |

60rad/s² |

|

16 |

Maximum angular acceleration of axis A |

60rad/s² |

|

17 |

Equipment size (length x width x height) |

≈6500mm×4600mm×3800mm |

|

18 |

Equipment footprint size (length x width x height) |

≈8200mm×6500mm×3800mm |

|

19 |

Machine weight |

≈12000kg |

|

20 |

Technical parameters of rotary workbench |

diameter :4000mm Maximum single side load: 500kg Single rotation time <4s |