1. Chii chinonzi silicon sheet?

Mapepa esimbi esilicon anoshandiswa nevashandi vemagetsi anozivikanwa semapepa esimbi esilicon. Imhando yeferrosilicon soft magnetic alloy ine kabhoni yakaderera zvikuru. Inowanzova nesilicon 0.5-4.5% uye inomonererwa nekupisa nechando. Kazhinji, ukobvu hwayo hunenge huri pasi pe1 mm, saka inonzi plate yakatetepa. Kuwedzerwa kwesilicon kunowedzera simba remagetsi resimbi uye simba remagetsi rakanyanya kupinda, zvichideredza kubatana, kurasikirwa nesimbi (kurasikirwa nesimbi) uye kukwegura kwemagnetic.

Pepa resilicon rinoshandiswa zvikuru kugadzira masimbi emhando dzakasiyana dzetransformer, mota nemajenareta.

Rudzi urwu rwesimbi yesilicon rune hunhu hwakanaka hwemagetsi, ndicho chinhu chakakosha uye chakakosha mumaindasitiri emagetsi, ekutaurirana uye ekushandisa zvishandiso.

2. Hunhu hwepepa resilicon

A. Kurasikirwa nesimbi shoma ndicho chiratidzo chakakosha chemhando. Nyika dzese pasi rose dzinoisa kurasikirwa nesimbi muzvikamu zvakaita segiredhi, kurasikirwa nesimbi kwakaderera, uye kunaka kwacho kuri nani.

B. Kupinza simba remagineti kwakanyanya. Pasi pesimba remagineti rimwe chete, pepa resilicon rinowana mukana wekushandisa simba remagineti wakakwira. Huwandu nehuremu hwesimbi yemota netransformer zvinogadzirwa nepepa resilicon zvidiki uye zvakareruka, saka zvinogona kuchengetedza mhangura, zvinhu zvinodzivirira kupisa.

C. Kuisa zvinhu zvakawanda. Nekunaka kwakatsetseka, ukobvu hwakati sandara uye hwakafanana, pepa resimbi resilicon rinogona kuunganidzwa zvakanyanya.

D. Nzvimbo yacho ine kunamatira kwakanaka kufirimu inodziisa uye iri nyore kuibatanidza.

3. Maitiro ekugadzira pepa resimbi resilicon anodiwa

Ukobvu hwechinhu: ≤1.0mm; zvakajairika 0.35mm 0.5mm 0.65mm;

➢ Zvinhu: ferrosilicon alloy

➢ Zvinodiwa pamifananidzo: yakavharwa kana kuti isina kuvharwa;

➢ Zvinodiwa pakunyatsorongeka: Kunyatsorongeka kweGiredhi 8 kusvika 10;

➢ Kureba kweGlitch kunodiwa: ≤0.03mm;

4. Maitiro ekugadzira pepa resimbi resilicon

➢ Kucheka: Kucheka inzira yekushandisa muchina wekuchekerera kana chigero. Chimiro chebasa chinowanzova nyore.

➢ Kuboora: Kuboora zvinoreva kushandiswa kwemamould pakuboora, kucheka maburi nezvimwewo. Maitiro acho akafanana nekuveura, kunze kwekuti mipendero yepamusoro neyepasi yekucheka inotsiviwa nemamould akakombama uye akakombama. Uye inogona kugadzira mamould ekuboora marudzi ese esimbi yesilicon.

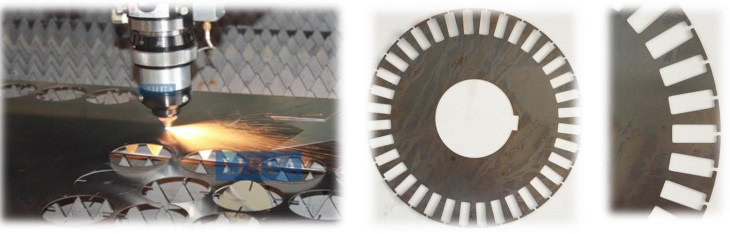

➢ Kucheka: Kushandisa muchina wekucheka nelaser kucheka marudzi ese ebasa. Uye zvishoma nezvishoma iri kuva nzira yakajairika yekucheka pepa resimbi resilicon.

➢Kupwanya: Sezvo iron chip burr ichikanganisa zvakananga mashandiro etransformer, saka kana kureba kweburr kwakakwirira kupfuura 0.03mm, kwaifanira kupwanywa usati wapenda.

➢ Kupenda: Pamusoro pesimbi pachapendwa nependi yakasimba, inodzivirira kupisa uye isingaparadzi ngura.

➢ Kuomesa: Pendi yesimbi yesilicon inofanira kuomeswa patembiricha yakati wozoigadzira yakasimba, yakasimba, ine simba re dielectric uye yakatsetseka pamusoro.

5. Kuenzanisa maitiro - kucheka nelaser

Kucheka neLaser: Chinhu chacho chinoiswa patafura yemuchina, uye chinocheka zvichienderana nepurogiramu yakatarwa kana mufananidzo. Kucheka neLaser inzira yekupisa.

Zvakanakira maitiro eLaser:

➢ Kugona kushanda nesimba, unogona kuronga mabasa ekugadzirisa chero nguva;

➢ Kunyatsogadzirwa zvakanaka, kunyatsogadzirwa zvakanaka kwemuchina wemazuva ese i0.01mm, uye muchina wekucheka nelaser wakanyatsogadzirwa i0.02mm;

➢ Kupindira kushoma nemaoko, unongoda kuseta maitiro uye ma parameter ekuita, wobva watanga kugadzirisa nebhatani rimwe chete;

➢ Kusvibiswa kweruzha rwekugadzirisa hakuna kukosha;

➢ Zvigadzirwa zvakapedzwa hazvina maburi;

➢ Basa rekugadzirisa rinogona kunge riri nyore, rakaoma uye rine nzvimbo isina muganho yekugadzirisa;

➢ Muchina wekucheka nelaser hauna kugadziriswa;

➢ Mutengo wakaderera wekushandisa;

➢ Kuchengetedza zvinhu, unogona kushandisa basa rekugovana miganhu kuburikidza nesoftware yekuisa matendere kuti uwane kurongeka kwakanaka kwebasa, uye kuwedzera kushandiswa kwezvinhu.

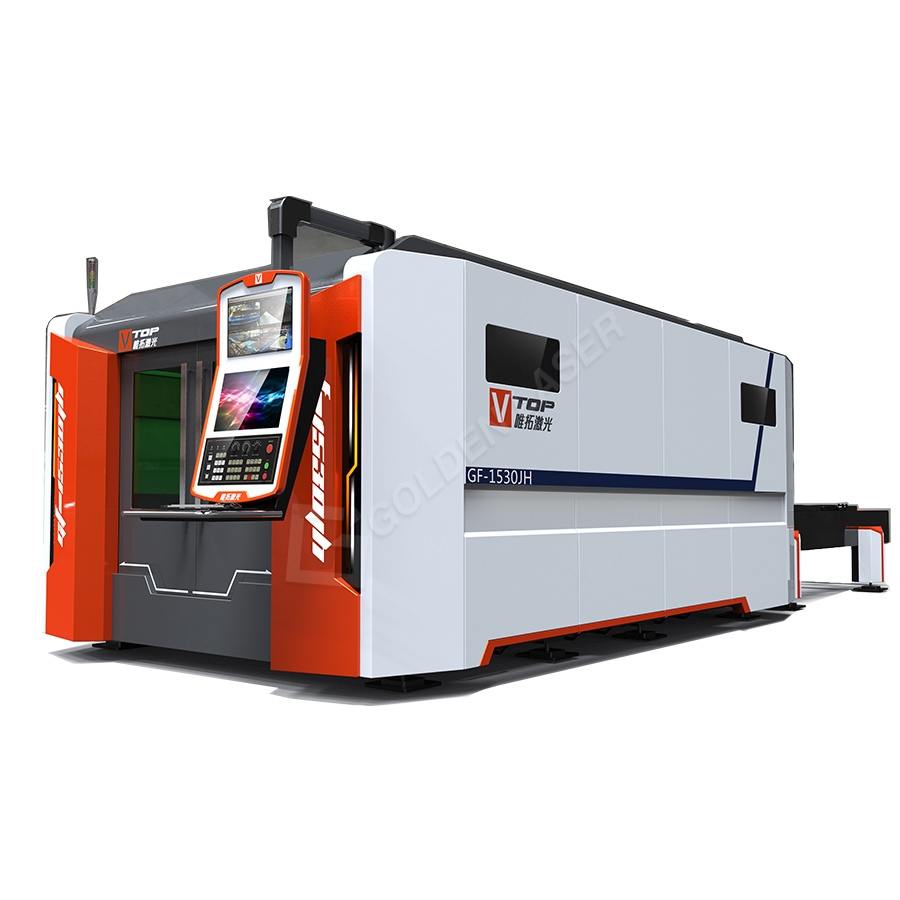

6. Mhinduro dzekucheka neLaser

Yakavhurika mhando 1530 fiber laser cutter GF-1530 High magadzirirwo elaser cutter GF-6060 Full yakavharirwa exchange table laser cutter GF-1530JH