1. Iyini ishidi le-silicon?

Amashidi ensimbi ye-silicon asetshenziswa ngogesi avame ukubizwa ngokuthi amashidi ensimbi ye-silicon. Luhlobo lwe-ferrosilicon soft magnetic alloy oluhlanganisa ikhabhoni ephansi kakhulu. Ngokuvamile luqukethe i-silicon engu-0.5-4.5% futhi lugoqwa ukushisa nokubanda. Ngokuvamile, ubukhulu bungaphansi kuka-1 mm, ngakho-ke lubizwa ngokuthi ipuleti elincane. Ukwengezwa kwe-silicon kwandisa ukumelana kukagesi kwensimbi kanye nokungena kwamandla kagesi okuphezulu, kunciphisa ukuxhumeka, ukulahlekelwa yi-core (ukulahlekelwa yinsimbi) kanye nokuguga kwamandla kagesi.

Ishidi le-silicon lisetshenziswa kakhulu ukwenza ama-core ensimbi e-transformers ahlukahlukene, ama-motor kanye nama-generator.

Lolu hlobo lweshidi lensimbi ye-silicon lunezakhiwo ezinhle kakhulu ze-electromagnetic, luyizinto ezibaluleke kakhulu nezibalulekile ze-magnetic embonini yamandla, ezokuxhumana kanye nezinsimbi.

2. Izici zeshidi le-silicon

A. Ukulahlekelwa yinsimbi ephansi kuyisibonakaliso esibaluleke kakhulu sekhwalithi. Wonke amazwe emhlabeni ahlukanisa ukulahlekelwa yinsimbi njengebanga, lapho ukulahlekelwa yinsimbi kuphansi, izinga liphezulu, futhi ikhwalithi iba ngcono.

B. Ukufakwa okuphezulu kwamandla kazibuthe. Ngaphansi kwensimu efanayo yamandla kazibuthe, ishidi le-silicon lithola ukuzwela okuphezulu kwamandla kazibuthe. Umthamo kanye nesisindo se-motor kanye ne-transformer iron core ekhiqizwa yishidi le-silicon kuncane futhi kulula, ngakho-ke kungonga ithusi, izinto zokuvikela.

C. Ukufakwa kwenqwaba ephezulu. Ngobuso obubushelelezi, ubukhulu obuyisicaba nobufanayo, ishidi lensimbi ye-silicon lingafakwa phezulu kakhulu.

D. Ubuso bunamathele kahle kwifilimu yokuvikela futhi kulula ukuwelda.

3. Imfuneko yenqubo yokukhiqiza ishidi lensimbi ye-silicon

Ubukhulu bezinto: ≤1.0mm; okuvamile 0.35mm 0.5mm 0.65mm;

➢ Izinto: i-ferrosilicon alloy

➢ Izidingo zesithombe: kuvaliwe noma akuvaliwe;

➢ Izidingo zokunemba: Ukunemba kwebanga lesi-8 kuya kwele-10;

➢ Imfuneko yokuphakama kwe-Glitch: ≤0.03mm;

4. Inqubo yokukhiqiza ishidi lensimbi ye-silicon

➢ Ukugunda: Ukugunda kuyindlela yokusebenzisa umshini wokugunda noma isikele. Isimo sengxenye yokusebenza ngokuvamile silula kakhulu.

➢ Ukushaya: Ukushaya kubhekisela ekusetshenzisweni kwezikhunta zokubhoboza, ukusika imigodi njll. Inqubo ifana nokusika, ngaphandle kokuthi imiphetho yokusika ephezulu nengezansi ithathelwa indawo yizikhunta ezigobile nezigobile. Futhi ingaklama izikhunta zokubhoboza zonke izinhlobo zeshidi lensimbi le-silicon.

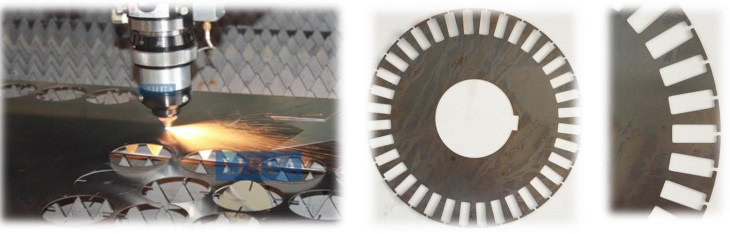

➢ Ukusika: Ukusebenzisa umshini wokusika nge-laser ukusika zonke izinhlobo zezinto zokusebenza. Futhi kancane kancane kuba yindlela evamile yokusika yokucubungula ishidi lensimbi le-silicon.

➢Ukugoba: Njengoba i-iron chip burr ithinta ngqo ukusebenza kwe-transformer, ngakho-ke uma ukuphakama kwe-burr kuphakeme kuno-0.03mm, kwakudingeka ukuthi ichotshozwe ngaphambi kokupenda.

➢ Ukupenda: Ubuso bensimbi buzopendwa ngefilimu yokupenda eqinile, engashisi futhi engagqwali.

➢ Ukomisa: Upende weshidi lensimbi ye-silicon kufanele womiswe ekushiseni okuthile bese uqina ube yifilimu ebushelelezi, eqinile, enamandla aphezulu e-dielectric.

5. Ukuqhathaniswa kwenqubo - ukusika nge-laser

Ukusikwa nge-laser: Izinto zibekwe etafuleni lomshini, futhi zizosikwa ngokwesimiso esihleliwe noma igrafu. Ukusikwa nge-laser kuyinqubo yokushisa.

Izinzuzo zenqubo ye-laser:

➢ Ukuguquguquka okuphezulu kokucubungula, ungahlela imisebenzi yokucubungula nganoma yisiphi isikhathi;

➢ Ukunemba okuphezulu kokucubungula, ukunemba okuvamile kokucubungula umshini kungu-0.01mm, kanti umshini wokusika we-laser onembile ungu-0.02mm;

➢ Ukungenelela okuncane ngesandla, udinga kuphela ukusetha izinqubo kanye nemingcele yenqubo, bese uqala ukucubungula ngenkinobho eyodwa;

➢ Ukungcola komsindo okwenziwayo akunamsebenzi;

➢ Imikhiqizo eqediwe ayinazo izimbobo;

➢ Umsebenzi wokucubungula ungaba lula, uyinkimbinkimbi futhi unesikhala esingenamkhawulo sokucubungula;

➢ Umshini wokusika nge-laser awunayo insizakalo;

➢ Izindleko eziphansi zokusebenzisa;

➢ Ukulondoloza izinto zokwakha, ungasebenzisa umsebenzi wokwabelana ngomphetho ngesofthiwe yokwakha isidleke ukuze ufeze ukuhlelwa okuhle kakhulu komsebenzi, futhi wandise ukusetshenziswa kwezinto zokwakha.

6. Izixazululo zokusika nge-laser

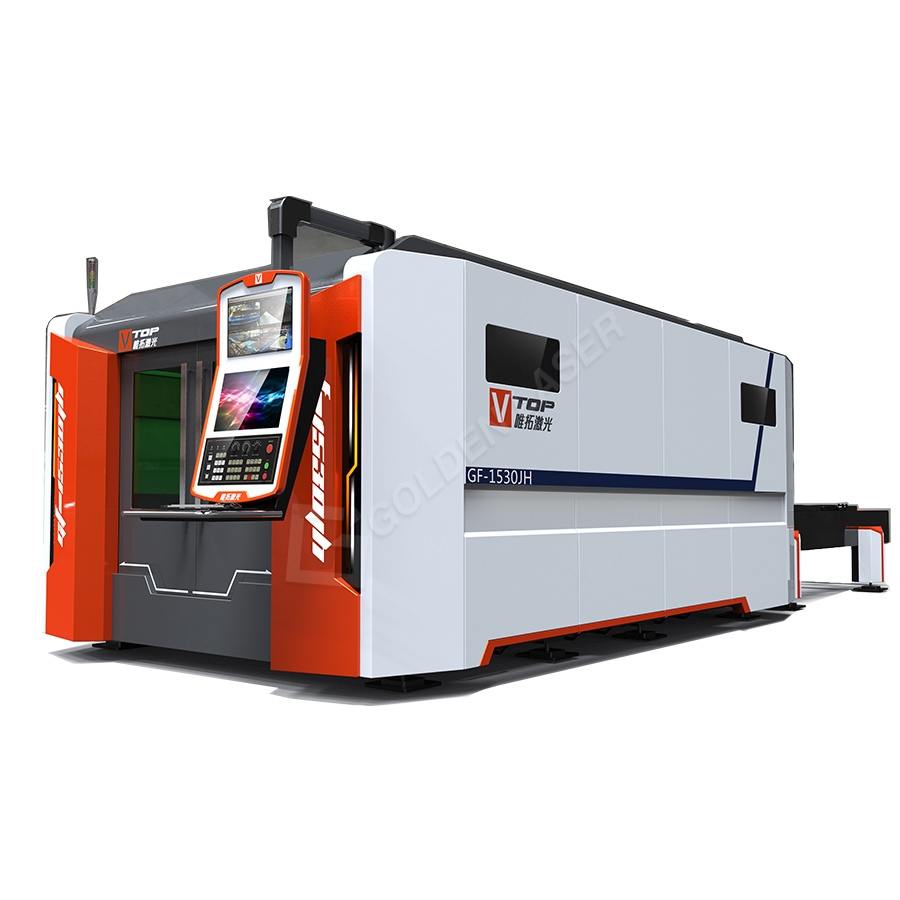

Umsiki we-laser wefayibha wohlobo lwe-1530 ovulekile GF-1530 Umsiki we-laser oqondile kakhulu GF-6060 Umsiki we-laser wethebula lokushintshana ogcwele ohlanganisiwe GF-1530JH