1. Kodi pepala la silikoni ndi chiyani?

Mapepala achitsulo a silicon omwe amagwiritsidwa ntchito ndi akatswiri amagetsi amadziwika kuti mapepala achitsulo a silicon. Ndi mtundu wa ferrosilicon soft magnetic alloy yomwe imakhala ndi carbon yochepa kwambiri. Nthawi zambiri imakhala ndi silicon ya 0.5-4.5% ndipo imazunguliridwa ndi kutentha ndi kuzizira. Nthawi zambiri, makulidwe ake ndi ochepera 1 mm, kotero amatchedwa mbale yopyapyala. Kuwonjezeredwa kwa silicon kumawonjezera mphamvu yamagetsi ya chitsulo komanso mphamvu yamagetsi yochulukirapo, kuchepetsa kulumikizana, kutayika kwa chitsulo (kutayika kwa chitsulo) komanso kukalamba kwa maginito.

Chipepala cha silicon chimagwiritsidwa ntchito kwambiri popanga ma cores achitsulo a ma transformer osiyanasiyana, ma mota ndi ma jenereta.

Mtundu uwu wa pepala lachitsulo la silicon uli ndi mphamvu zabwino kwambiri zamagetsi, ndi zipangizo zamaginito zofunika kwambiri komanso zofunika kwambiri m'mafakitale amagetsi, mauthenga ndi zida zamagetsi.

2. Makhalidwe a pepala la silikoni

A. Kutaya chitsulo chochepa ndiye chizindikiro chofunikira kwambiri cha ubwino. Mayiko onse padziko lapansi amaika kutayika kwa chitsulo m'gulu la giredi, kutayika kwa chitsulo kukakhala kochepa, giredi yapamwamba, komanso ubwino wake umakhala wabwino.

B. Mphamvu ya maginito yapamwamba. Pansi pa mphamvu ya maginito yomweyi, pepala la silicon limakhala ndi mphamvu ya maginito yambiri. Kuchuluka ndi kulemera kwa injini ndi chitsulo cha transformer chomwe chimapangidwa ndi pepala la silicon ndi kochepa komanso kopepuka, kotero chimatha kusunga mkuwa, zinthu zotetezera kutentha.

C. Kuyika zinthu zambiri. Ndi malo osalala, osalala komanso okhuthala mofanana, pepala lachitsulo la silicon limatha kuyika zinthu zambiri pamwamba.

D. Pamwamba pake pali kumatirira bwino ku filimu yotetezera kutentha ndipo ndikosavuta kuwotcherera.

3. Chofunikira pakupanga njira zopangira mapepala achitsulo a silicon

Kukhuthala kwa zinthu: ≤1.0mm; wamba 0.35mm 0.5mm 0.65mm;

➢ Zipangizo: aloyi wa ferrosilicon

➢ Zofunikira pazithunzi: kutsekedwa kapena kusatsekedwa;

➢ Zofunikira pa kulondola: Kulondola kwa Giredi 8 mpaka 10;

➢ Kufunika kwa kutalika kwa glitch: ≤0.03mm;

4. Njira yopangira mapepala achitsulo a silicon

➢ Kumeta: Kumeta ndi njira yogwiritsira ntchito makina ometa kapena lumo. Kapangidwe ka ntchito nthawi zambiri kamakhala kosavuta.

➢ Kuboola: Kuboola kumatanthauza kugwiritsa ntchito nkhungu poboola, kudula mabowo ndi zina zotero. Njirayi ndi yofanana ndi kumeta, kupatula kuti m'mphepete mwa kudula pamwamba ndi pansi mumalowedwa m'malo ndi nkhungu zozungulira komanso zopingasa. Ndipo imatha kupanga nkhungu zoboola mitundu yonse ya pepala lachitsulo la silicon.

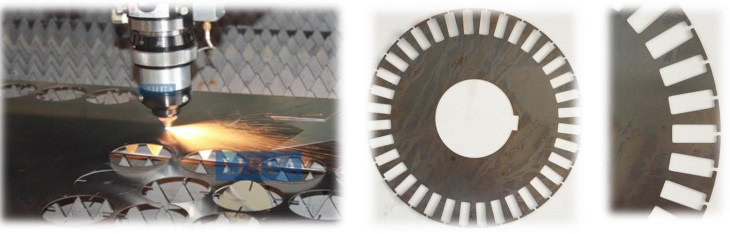

➢ Kudula: Kugwiritsa ntchito makina odulira a laser kudula mitundu yonse ya zinthu zogwirira ntchito. Ndipo pang'onopang'ono ikukhala njira yodulira yodziwika bwino yopangira pepala lachitsulo la silikoni.

➢Kupindika: Popeza chipolopolo chachitsulo chimakhudza mwachindunji magwiridwe antchito a transformer, kotero ngati kutalika kwa chipolopolocho kuli kokwera kuposa 0.03mm, chimayenera kuphwanyidwa musanachipente.

➢ Kupaka: Pamwamba pa chitsulo padzapakidwa utoto wolimba, wosatentha komanso woonda wosagwira dzimbiri.

➢ Kuumitsa: Utoto wa pepala lachitsulo la silicon uyenera kuumitsidwa pa kutentha kwina kenako nkuumitsa kukhala filimu yolimba, yolimba, ya dielectric komanso yosalala pamwamba.

5. Kuyerekeza njira - kudula kwa laser

Kudula ndi laser: Zipangizozo zimayikidwa patebulo la makina, ndipo zimadula malinga ndi pulogalamu yokonzedweratu kapena chithunzi. Kudula ndi laser ndi njira yotenthetsera.

Ubwino wa njira ya laser:

➢ Kusinthasintha kwakukulu kwa ntchito zogwirira ntchito, mutha kukonza ntchito zogwirira ntchito nthawi iliyonse;

➢ Kulondola kwambiri pakupanga makina, kulondola kwa makina wamba ndi 0.01mm, ndipo makina odulira laser olondola ndi 0.02mm;

➢ Kugwiritsa ntchito njira zochepa pamanja, muyenera kungokhazikitsa njira ndi magawo a njira, kenako yambani kukonza ndi batani limodzi;

➢ Kuipitsidwa kwa phokoso lopangidwa ndi makina oyeretsera zinthu n'kochepa;

➢ Zogulitsa zomalizidwa zimakhala zopanda ma burrs;

➢ Ntchito yopangira zinthu ingakhale yosavuta, yovuta komanso ili ndi malo opanda malire ogwirira ntchito;

➢ Makina odulira a laser ndi opanda kukonza;

➢ Mtengo wotsika wogwiritsa ntchito;

➢ Kusunga zipangizo, mutha kugwiritsa ntchito ntchito yogawana m'mphepete kudzera mu pulogalamu yopangira chisa kuti mukwaniritse bwino ntchito yogwirira ntchito, ndikuwonjezera kugwiritsa ntchito zinthuzo.

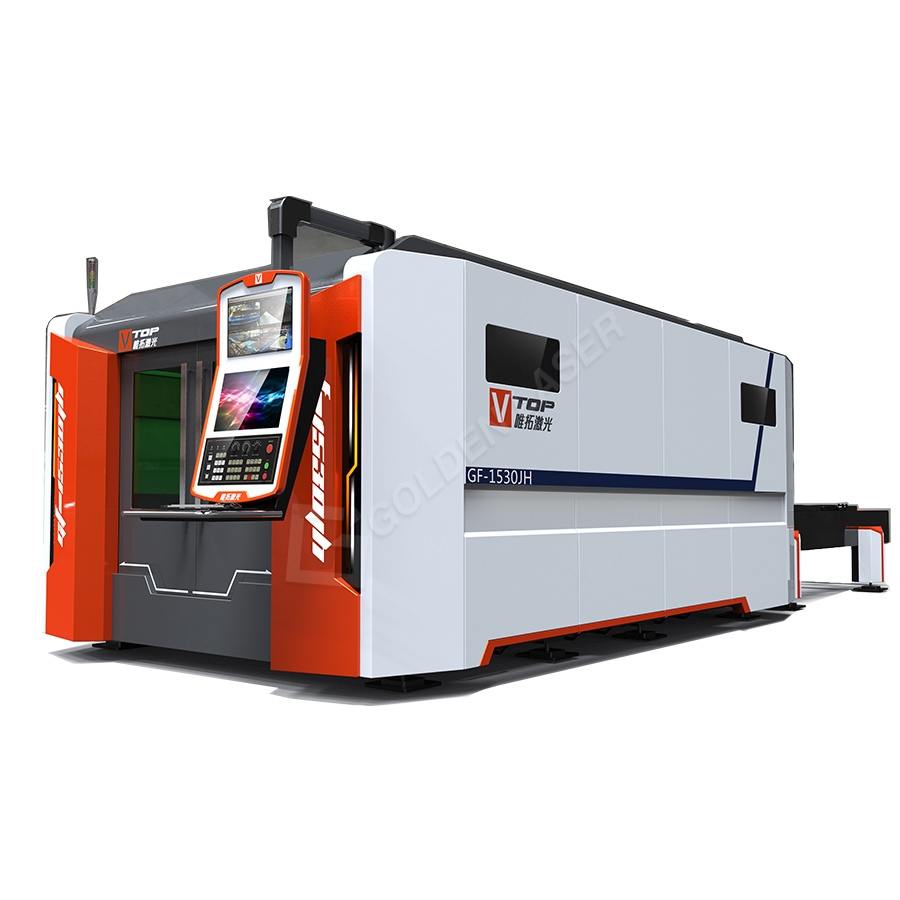

6. Mayankho odulira a laser

Chodula cha laser chamtundu wotseguka cha 1530 GF-1530 Chodula cha laser cholondola kwambiri GF-6060 Chodula cha laser cha tebulo losinthira GF-1530JH