Ingxaki ekhoyo ngoku kushishino lokuvelisa ifenitshala yentsimbi

1. Le nkqubo iyinkimbinkimbi: ifenitshala yendabuko ithatha inkqubo yokwenziwa kwemizi-mveliso yokukhetha—ukusika iibhedi ngesarha—ukucubungula umatshini ngokujika—umphezulu othe tyaba—ukugrumba, ukuvala indawo kunye nokubhoboza—ukugrumba—ukucoca—ukuwelda kokudlulisa kufuna iinkqubo ezili-9.

2. Kunzima ukuyicubungula ityhubhu encinci: iinkcukacha zezinto zokwenza ifanitshala aziqinisekanga. Eyona incinci yile10mm*10mm*6000mm, kwaye ubukhulu bodonga lombhobho ngokubanzi0.5-1.5mm. Eyona ngxaki inkulu ekucutshungulweni kombhobho omncinci kukuba umbhobho ngokwawo awunabugorha kwaye uguqulwa lula ngamandla angaphandle, njengokugoba kombhobho, ukujija, kunye nokudumba emva kokukhupha. Iinkqubo zemveli zokucubungula, ezifana nokusika umatshini wokusarha, icandelo lokucubungula umatshini wokusarha kunye nokujija, ukubhoboza nge-punch, ukubhola umatshini wokubhola, njl.njl., ziindlela zokucubungula uqhagamshelwano ezinyanzela imo yombhobho ukuba iguqulwe ngamandla angaphandle, kunye neenkqubo ezininzi kunye nabantu abaninzi Ukuhamba kokucubungula, amandla okukhusela ombhobho phantse akukho, rhoqo ukuya kwinqanaba lokugqibela lemveliso egqityiweyo, umphezulu wombhobho ukrwelwe okanye ude waguqulwa, kwaye ufuna ukulungiswa kwesandla okwesibini, okuthatha ixesha kwaye kunzima.

3. Ukuchaneka koomatshini okungasebenzi kakuhle: Phantsi kwendlela yesiqhelo yokucubungula ipayipi yefenitshala yentsimbi, ukuchaneka ngokubanzi kwepayipi akunakuqinisekiswa. Nokuba kukusebenza njengomatshini wokusarha, umatshini wokubhoboza okanye umatshini wokubhola, kukho iimpazamo zoomatshini, ngakumbi kwizixhobo zokucubungula ezinolawulo oluphantsi lokuzenzekelayo. Okukhona ulandelelwano lwenkqubo luphezulu, kokukhona impazamo yoomatshini iqokelelana. Zonke iindlela zokucubungula ezingentla zifuna ukungenelela komntu kulawulo lwenkqubo, kwaye iimpazamo zomntu ziya kongezwa kwimpazamo yokugqibela yokuchaneka kwemveliso. Ke ngoko, ukuchaneka kwendlela yesiqhelo yokucubungula iinkqubo ezininzi akulawuleki kwaye akuqinisekisiwe. Kwinqanaba lokugqibela lemveliso, ukulungiswa nokulungiswa ngesandla yimeko eqhelekileyo.

4. Ukusebenza kakuhle kokucubungula: Umatshini wokusarha unezibonelelo ezithile zokusika kunye nokutshaya imibhobho emininzi ngaxeshanye, kodwa ukusebenza kakuhle kokuvula umbhobho kuphantsi kakhulu, kwaye kuyimfuneko ukutshintsha i-engile yokusika kunye nendawo yeblade yesarha ukuze kubekwe kwaye kunqunyulwe ngeendlela ezininzi, nto leyo engasebenzi kakuhle kwaye ingenakufezekiswa. Ukuchaneka kokulawula. Ii-punch press zingasetyenziselwa ukubhoboza imingxuma eqhelekileyo efana nemingxunya ejikelezileyo kunye nemingxunya eyisikwere. Nangona kunjalo, kukho iintlobo ezininzi zemingxunya kwishishini lefenitshala. Umatshini wokubhoboza unamandla amaninzi okucubungula imingxunya enjalo, ngaphandle kokuba umthengi ubangela ukuba bachithe amava angakumbi kunye neendleko zokuphuhlisa iintlobo ngeentlobo zeenkuni. Wonke umntu uyazi ukuba umatshini wokugrumba unokucubungula imingxunya ejikelezileyo kuphela, kwaye ukusebenza kuncinci kakhulu. Imida yokucubungula kunye nokungasebenzi kakuhle kwenkqubo nganye kuphumela ekungasebenzi kakuhle kwimveliso iyonke.

5. Iindleko eziphezulu zabasebenzi: Kwindlela yokusarha, ukubhoboza kunye nokubhoboza ngendlela yesiqhelo yokucubungula, uphawu olukhulu kukungenelela komntu. Ukusebenza kwesixhobo ngasinye kufuneka kugcinwe ngesandla, kuba ukuzenzekela kwezixhobo ezinjalo kuphantsi kakhulu. Kwindlela yokucubungula izinto ezinjalo ezingezizo iishiti zeepayipi, ulawulo lwesandla luyafuneka kwinxalenye nganye yokondla, ukubeka, ukucubungula kunye nokubuyisela. Ke ngoko, kunokubonwa rhoqo kwindawo yokusebenzela yokucubungula ifenitshala, izixhobo ezininzi, abasebenzi abaninzi. Kule mihla, ngophuhliso lweemeko zemarike, abanini bamashishini bakhala ngokuba abasebenzi baya behambahamba ngakumbi, kwaye baya besiba nzima ngakumbi ukubaqesha. Iimfuno zomvuzo zabasebenzi nazo ziyanda. Iindleko zabasebenzi zinokuba negalelo elikhulu kwinzuzo yeenkampani.

6. Umgangatho wemveliso ophantsi: Ukuchaneka kunye nomgangatho wombhobho ogqityiweyo kuchaphazela ngokuthe ngqo imveliso yokugqibela. I-Burr, ukuguqulwa komatshini ojikelezayo, ukungcola eludongeni lwangaphakathi lombhobho, njl.njl. akuvumelekanga kwimveliso yefenitshala ephezulu. Nangona kunjalo, nokuba kukusika umatshini, ukubhoboza, okanye ukubhola, akungathandabuzeki ukuba ezi ngxaki ziya kuvela emva kokucubungula umbhobho. Umsebenzi wokususa ii-burst ngesandla, ukusika, kunye nokucoca kwimisebenzi elandelayo awunakuphepheka.

7. Kukho ukungabikho kokuguquguquka okukhulu: Kule mihla, imfuno yabathengi iya isiba yinto eyenzelwe wena ngakumbi, ngoko ke uyilo lwefenitshala yexesha elizayo ngokuqinisekileyo luyenziwa lube lolwakho ngakumbi nangakumbi. Umatshini wokusarha wendabuko, umatshini wokubhoboza, umatshini wokubhola kunye nezinye izixhobo zindala, kwaye ubugcisa obulula abunakuxhasa uyilo olutsha kunye nokuphefumlelwa kobuchule. Khazimla ube yinyani. Ukungasebenzi kakuhle, umgangatho ophantsi, kunye nokusilela kweendleko eziphezulu kwendlela yokucubungula yendabuko kuya kuyithintela kakhulu isantya sophando kunye nophuhliso lweemveliso ezintsha, kwaye kunike imakethi isiqalo esihle.

Zeziphi izinto ezintsha ezinokuziswa ngumsiki wepayipi yelaser ozenzekelayo ngokupheleleyo kwifenitshala

Ishishini lokuvelisa? Zithini iimpawu zezixhobo?

1. Amandla amatsha aphambili ekucutshungulweni kwemibhobho yesinyithi ye-bismuth: ukusika i-laser yefayibha sisixhobo esitsha sokucubungula isinyithi kwiminyaka yakutshanje. Kamva, ithatha indawo yokucheba yendabuko, ukubhoboza, ukubhola kunye nokusarha. Izinto zepayipi nazo ziyintsimbi, kwaye umbhobho weshishini lefenitshala wenziwe ngentsimbi engagqwaliyo, nto leyo ehambelana neenzuzo zokusika i-laser yefayibha. Ukusebenza kakuhle kokuguqulwa kwe-photoelectric ye-laser yefayibha, umgangatho ogqwesileyo we-beam, amandla e-laser agxile kakhulu, umsantsa wokusika omncinci, ungasetyenziswa ekucutshungulweni kwemibhobho yeshishini lefenitshala. I-rotary chuck yomatshini wokusika i-laser yefayibha ye-Vexo laser ngokuzenzekelayo ngokupheleleyo inesantya sokujikeleza esifikelela kwi-120 rpm, kunye nokukwazi kwe-laser yefayibha ukusika intsimbi engagqwaliyo ngesantya esiphezulu kakhulu. Ukudibana kwezi zimbini kwenza ukusebenza kakuhle kokucubungula imibhobho kube sisiqingatha somzamo. Kwangaxeshanye, xa i-laser yefayibha isika umbhobho, intloko yokusika i-laser ayiqhagamshelani nombhobho, kodwa iboniswa nge-laser kumphezulu wombhobho ukuze inyibilike kwaye inqunyulwe, ngoko ke ikwimo yokusebenza engangqubaniyo, ithintela ngempumelelo ingxaki yokuguqulwa kwemibhobho phantsi kwendlela yokusebenza yendabuko. Inxalenye esikiweyo yi-fiber laser icocekile kwaye igudile, kwaye akukho burr emva kokusikwa. Ke ngoko, iingenelo ezimbini zokusebenza kakuhle kunye nomgangatho zisiqinisekiso esibalulekileyo sokuba i-fiber laser isikwe ibe yeyona nto intsha iphambili ekucutshungulweni kwemibhobho yesinyithi.

2. Uqwalaselo olwenziwe ngokwezifiso ukunceda ukusebenza kakuhle kokucubungula kunye nokuphucula umgangatho: kwishishini lefenitshala, izinto ezincinci, ezincinci, ikakhulu ziimpawu zentsimbi engagqwaliyo, sisebenzisa uqwalaselo olujolise ekuphuculeni ukusebenza kakuhle kokucubungula kunye nomgangatho wokucubungula umbhobho weshishini lefenitshala. I-laser yefayibha yemodyuli ekhethekileyo, ifayibha ekhethekileyo, intloko yokusika i-laser yefayibha engagqwaliyo, zonke izibonelelo zoqwalaselo zigxile kubuchule bokusika bombhobho okhethekileyo kwishishini lefenitshala, ukusebenza kakuhle kombhobho wentsimbi engagqwaliyo wenkcazo efanayo kunqunyulwa ngumatshini wethu wokusika i-laser yefayibha eqhelekileyo Phantse i-30%, ngelixa kuzisa iziphumo zokusika ezingcono.

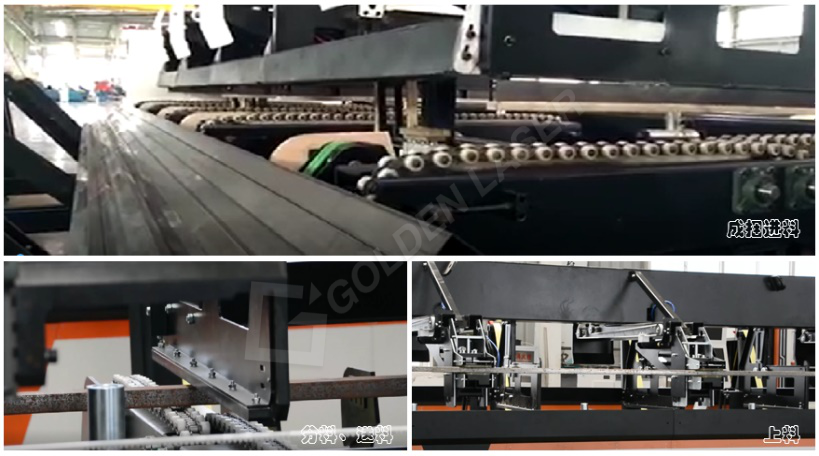

3. Ukuveliswa kweepayipi ngokuzenzekelayo: Emva kokuba iipayipi ezihlanganisiweyo zibekwe kumatshini wokondla ozenzekelayo, iqhosha elinye liyaqaliswa, kwaye iipayipi zinikwa ngokuzenzekelayo, zahlulwe, zondliwa, zibotshelelwe ngokuzenzekelayo, zondliwa, zinqunyulwe kwaye zikhutshwe ngexesha elinye. Ngenxa yomsebenzi wethu wokulayisha nokukhupha ngokuzenzekelayo ophuhliswe kumatshini wokusika iipayipi ze-laser ozenzekelayo ngokupheleleyo, ipayipi inokufezekisa ithuba lokucubungula iipakethi. Izinto ezincinci zepayipi kushishino lwefenitshala zithatha indawo encinci. Uhlobo olufanayo lwezixhobo lunokupakisha iipayipi ezininzi kumthwalo omnye, ngoko ke luneengenelo ezingaphezulu. Umntu omnye usemsebenzini, kwaye yonke inkqubo igqitywa ngokuzenzekelayo. Olu luphawu lokusebenza kakuhle.

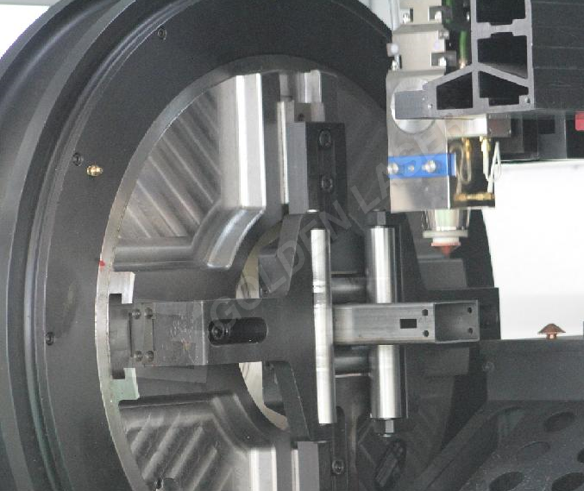

4. Ukuphumla kokubambelela kwityhubhu: Kwityhubhu encinci yeshishini lefenitshala, ityhubhu yokusika nge-laser iqinile ngakumbi. Ukuba amandla okubambelela makhulu kakhulu, umbhobho uyaguquguquka lula, amandla okubambelela mancinci kakhulu, kwaye ubude bombhobho bude. Ngexesha lenkqubo yokusika, umbhobho ujikeleza ngesantya esiphezulu kwaye ukhululeka lula. Ke ngoko, amandla okubambelela kwityhubhu yezixhobo zokunqumla umbhobho kwishishini lefenitshala kufuneka ahlengahlengiswe, kwaye indlela yokulungisa ingxaki kufuneka iqatshelwe ngokulula. Ityhubhu yepneumatic ezizimelayo elungiselelwe ngumatshini wokusika umbhobho we-laser ozenzekelayo ngokupheleleyo inokuzenzela ukuzimela kwindawo yokubambelela kumbhobho, kanye kwindawo yokubambelela, kwaye iziko lombhobho libekwe kanye. Kwangaxeshanye, amandla okubambelela kwityhubhu avela kuxinzelelo lomoya olungenayo. Umgca wokufaka igesi uxhotyiswe ngevalvu yokulawula uxinzelelo lwegesi, kwaye amandla okubambelela anokulungiswa lula ngokujikeleza iqhosha kwivalvu yokulawula uxinzelelo lomoya.

5. Amandla okuxhasa asebenzayo nanokuthenjwa: Okukhona ubude bombhobho bude, kokukhona ukuguguleka kombhobho kusiba nzima emva kokuba uxhonyiwe. Emva kokuba umbhobho ulayishiwe, nangona i-chuck ibotshelelwe ngaphambi nasemva, inxalenye ephakathi yombhobho iya kugoba ngenxa yomxhuzulane, kwaye ukujikeleza kwesantya esiphezulu kombhobho kuya kuba yindlela yokutsiba, ngoko ke ukunqumla kuya kuchaphazela ukuchaneka kokusika kombhobho. Ukuba indlela eqhelekileyo yokulungisa ngesandla yenkxaso yezinto eziphezulu iyamkelwa, kuphela iimfuno zenkxaso yombhobho ojikelezayo kunye nombhobho wesikwere ezinokusonjululwa, kodwa ekusikeni kombhobho wohlobo lwecandelo olungaqhelekanga njengombhobho ongxande kunye nombhobho o-elliptical, ukulungiswa ngesandla kwenkxaso yezinto eziphezulu akusebenzi. . Ke ngoko, inkxaso ephezulu edadayo kunye nenkxaso yomsila yoqwalaselo lwezixhobo zethu sisisombululo sobungcali. Xa umbhobho ujikeleza, uya kubonisa iindlela ezahlukeneyo zokumiswa kwindawo. Inkxaso yezinto eziphezulu ezidadayo kunye nenkxaso yezinto zomsila zinokulungisa ngokuzenzekelayo ukuphakama kwenkxaso ngexesha langempela ngokwendlela umbhobho otshintsha ngayo, ukuze kuqinisekiswe ukuba umzantsi wombhobho uhlala ungahlukani ukusuka phezulu kombhobho wenkxaso, odlala impembelelo yenkxaso enamandla yombhobho. Inkxaso yezinto eziphezulu ezidadayo kunye nenkxaso yezinto zomsila ezidadayo zisebenza kunye ukugcina uzinzo kwindawo yombhobho ngaphambi nasemva kokusika, ngaloo ndlela kuqinisekiswa ukuchaneka kokusika.

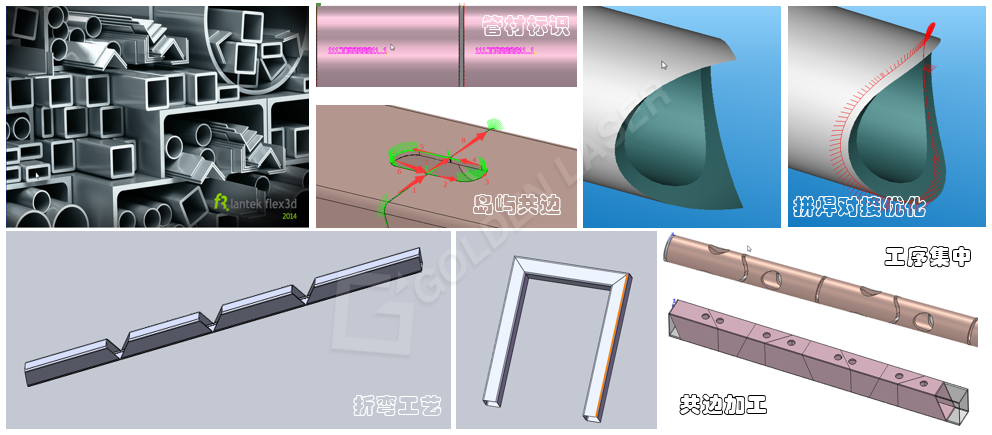

6. Uxinzelelo lwenkqubo kunye nokwahluka kweenkqubo: sebenzisa isoftware yokudweba ye-3D ukuyila iipateni ezahlukeneyo ekufuneka zicutshungulwe, ezinje ngokusika, ukujija, ukuvula, ukutshiza, ukumakisha, njl.njl., uze uziguqule zibe ziinkqubo zomatshini we-NC ngenyathelo elinye ngesoftware yobungcali yokwenza izidleke. , ufake kwinkqubo yobungcali ye-CNC yoqwalaselo lwesixhobo, uze ufumane iiparameter zenkqubo yokusika ezihambelanayo kwisiseko sedatha yenkqubo, kwaye umshini ungaqalwa ngeqhosha elinye. Inkqubo yokusika ezenzekelayo igqibezela ukusarha kwendabuko, imoto, ukubhoboza, ukubhola kunye nezinye iinkqubo. Ukugqitywa kwenkqubo okuphakathi kuzisa ukuchaneka kokucubungula okulawulekayo nokuqinisekisiweyo, kunye nokusebenza kakuhle okuphezulu kunye neendleko eziphantsi. Olu kongeza kunye nokuthabatha iingxaki zezibalo kufuneka lucace kubo bonke abaqhubi beshishini.

7. Ukusetyenziswa koomatshini bokusika i-fiber laser yobungcali kwiipayipi zoshishino lwefenitshala yentsimbi kuzise utshintsho olutsha kwitekhnoloji yokucubungula imibhobho. Ukususela oko saqala uphando nophuhliso lomatshini wokusika i-fiber laser ozenzekelayo ngokupheleleyo, sizibeke kwindawo yethu kushishino, senza ishishini libe nzulu, lichwephesha, kwaye licokisekile. Ishishini lefenitshala yentsimbi libe yimeko yomzekelo kumatshini wethu wokusika imibhobho. Kwindlela yophando nophuhliso, uphando kunye nophuhliso kwiminyaka edlulileyo, siqokelele amava amaninzi obuchwephesha kwaye saphuhlisa izinto ezintsha ezisebenzayo nezintsha kushishino lokuvelisa ifanitshala. Inkqubo. Isidingo sokuqala sokudityaniswa, ngoku sinokubotshwa kwaye silungiswe; isidingo sokuqala sokudityaniswa, sinokugotywa ngokuthe ngqo; ukusetyenziswa kombhobho wokuqala kuphantsi kakhulu, ngoku singasebenzisa umsebenzi oqhelekileyo wokusika umphetho ukufezekisa ukonga okungcono kwemibhobho kunye neemveliso ezininzi Ngaphandle, njalo njalo, ezi ndlela zintsha zokucubungula zisetyenziswa kwimeko yokucubungula imibhobho kushishino lwefenitshala, kwaye iingenelo zibasebenzisi bezixhobo zethu.

Umatshini wokusika i-Laser weFenitshala yesinyithi