Vuto lomwe lilipo panopa pamakampani opanga mipando yachitsulo

1. Njirayi ndi yovuta: mipando yachikhalidwe imatenga njira zopangira mafakitale—kudula bedi—kutembenuza makina—kukonza malo otsetsereka—kuboola malo otetezedwa ndi kuboola—kuboola—kuyeretsa—kuwotcherera kosinthira kumafuna njira 9.

2. Kukonza chubu chaching'ono n'kovuta: kufotokozera za zipangizo zopangira mipando sikudziwika. Chaching'ono kwambiri ndi10mm*10mm*6000mm, ndipo makulidwe a khoma la chitoliro nthawi zambiri amakhala0.5-1.5mmVuto lalikulu pakukonza chitoliro chaching'ono ndilakuti chitolirocho chimakhala cholimba pang'ono ndipo chimasokonekera mosavuta ndi mphamvu zakunja, monga kupindika chitoliro, kupindika, ndi kuphulika pambuyo potulutsa. Njira zachikhalidwe zokonzera, monga kudula makina odulira, kudula gawo la makina odulira ndi kuluka, kuboola nkhonya, kuboola makina odulira, ndi zina zotero, ndi njira zogwirira ntchito zomwe zimakakamiza mawonekedwe a chitoliro kuti asinthidwe ndi mphamvu zakunja, kuphatikiza njira zambiri ndi anthu ambiri. Kuyenda kwa processing, mphamvu yoteteza ya chitoliro ndi pafupifupi palibe, nthawi zambiri mpaka gawo lomaliza la chinthu chomalizidwa, pamwamba pa chitolirocho pakhala pakukanda kapena kusokonekera, ndipo pamafunika kukonza kwachiwiri pamanja, komwe kumatenga nthawi komanso kovuta.

3. Kulondola kolakwika kwa makina opangira: Malinga ndi njira yachikhalidwe yopangira chitoliro cha mipando yachitsulo, kulondola konse kwa chitoliro sikungatsimikizidwe. Kaya ndi makina opangira monga makina odulira, makina obowola kapena makina obowola, pali zolakwika za makina opangira, makamaka pazida zogwirira ntchito zomwe zili ndi mphamvu yotsika yowongolera zokha. Kuchuluka kwa ndondomeko ya ntchito, kulakwitsa kwa makina opangira kumawonjezeka. Njira zonse zogwirira ntchito zomwe zili pamwambapa zimafuna kuti anthu alowererepo pakuwongolera njira, ndipo zolakwika za anthu zidzawonjezedwa ku kulakwitsa komaliza kwa kulondola kwa chinthu. Chifukwa chake, kulondola kwa njira yachikhalidwe yopangira zinthu zambiri sikungathe kulamuliridwa komanso kutsimikizika. Pa gawo lomaliza la chinthu, kukonza ndi kukonza pamanja ndi mkhalidwe wabwinobwino.

4. Kugwiritsa ntchito bwino pang'ono: Makina odulira ali ndi ubwino wina wodulira ndi kugwetsa mapaipi osiyanasiyana, koma kugwiritsa ntchito bwino kwa kutsegula kwa chitoliro ndi kochepa kwambiri, ndipo ndikofunikira kusintha ngodya yodulira ndi malo a tsamba la saw kuti liyike ndi kudula mosiyanasiyana, zomwe sizigwira ntchito bwino kapena sizingatheke. Kulondola kowongolera. Makina odulira angagwiritsidwe ntchito pobowola mabowo okhazikika monga mabowo ozungulira ndi mabowo ang'onoang'ono. Komabe, pali mitundu yambiri ya mabowo mumakampani opanga mipando. Makina odulira ali ndi luso lochulukirapo lokonza mabowo otere, pokhapokha ngati kasitomala apangitsa kuti agwiritse ntchito luso lochulukirapo komanso ndalama zambiri popanga mitundu yosiyanasiyana ya nkhungu. Aliyense amadziwa kuti makina odulira amatha kukonza mabowo ozungulira okha, ndipo kukonza kumakhala kochepa. Zofooka zokonza ndi kusagwira ntchito bwino kwa njira iliyonse zimapangitsa kuti zinthu zisamayende bwino.

5. Mtengo wokwera wa antchito: Pa kudula, kuboola ndi kuboola m'njira yachikhalidwe yopangira zinthu, chinthu chachikulu kwambiri ndi kulowererapo kwa anthu. Kugwira ntchito kwa chipangizo chilichonse kuyenera kutetezedwa ndi manja, chifukwa makina odziyimira pawokha a zida zotere ndi otsika kwambiri. Pakukonza zinthu zopanda mapepala zogwirira ntchito za mapaipi, kuyang'anira pamanja ndikofunikira pa gawo lililonse la chakudya, malo, kukonza ndi kubwezeretsa. Chifukwa chake, nthawi zambiri zimatha kuwoneka m'malo opangira mipando, zida zambiri, antchito ambiri. Masiku ano, chifukwa cha kukula kwa msika, eni mabizinesi akudandaula kuti antchito akukhala oyenda kwambiri, ndipo akuvuta kuwalemba ntchito. Zofunikira pamalipiro a antchito zikukweranso. Ndalama za antchito zitha kukhala gawo lalikulu la phindu la makampani.

6. Ubwino wa chinthu: Kulondola ndi ubwino wa chitoliro chomalizidwa zimakhudza mwachindunji chinthu chomaliza. Burr, kusintha kwa makina, dothi lamkati mwa chitoliro, ndi zina zotero siziloledwa popanga mipando yapamwamba. Komabe, kaya ndi kudula makina, kuboola, kapena kuboola, n'zosakayikitsa kuti mavutowa adzawonekera pambuyo pokonza chitolirocho. Kuchotsa chitolirocho ndi manja, kudula, ndi kuyeretsa ntchito zina sizingapeweke.

7. Pali kusowa kwakukulu kwa kusinthasintha: Masiku ano, kufunikira kwa ogula kukuchulukirachulukira, kotero kapangidwe ka mipando yamtsogolo kamakhala kapadera kwambiri. Makina odulira akale, makina obowola, makina obowola ndi zida zina ndi akale, ndipo luso losavuta silingathe kuthandizira kapangidwe katsopano ndi kudzoza kwa luso. Kuwala kukhala zenizeni. Kusagwira ntchito bwino, khalidwe lotsika, ndi zofooka zokwera mtengo za njira yopangira zinthu zachikhalidwe zidzalepheretsa kwambiri liwiro la kafukufuku ndi chitukuko cha zinthu zatsopano, ndikupatsa msika chiyambi chabwino.

Kodi chodulira mapaipi a laser chokhachokha chingabweretse zinthu zatsopano ziti ku mipando?

Kodi makampani opanga zinthu? Kodi zidazi zimakhala ndi makhalidwe otani?

1. Mphamvu yatsopano yogwiritsira ntchito mapaipi achitsulo a bismuth: kudula kwa laser ya ulusi ndi chida chatsopano chogwiritsira ntchito zitsulo m'zaka zaposachedwa. Pambuyo pake, pang'onopang'ono ikusintha kudula kwachikhalidwe, kuboola, kuboola ndi kudula. Zipangizo za chitolirocho ndi chitsulo, ndipo chitoliro cha mafakitale a mipando chimapangidwa ndi chitsulo chosapanga dzimbiri, zomwe zikugwirizana ndi ubwino wodula kwa laser ya ulusi. Kugwira ntchito bwino kwa kusintha kwa kuwala kwa kuwala kwa ulusi wa laser, khalidwe labwino kwambiri la beam, mphamvu ya laser yokhazikika kwambiri, kusiyana kodulira bwino, kungagwiritsidwe ntchito pokonza mapaipi a mafakitale a mipando. Chuck yozungulira ya makina odulira a laser a Vexo laser odzipangira okha ali ndi liwiro lozungulira la mpaka 120 rpm, ndipo luso la laser ya ulusi kudula chitsulo chosapanga dzimbiri pa liwiro lapamwamba kwambiri. Kuphatikiza kwa ziwirizi kumapangitsa kuti ntchito yokonza mapaipi ikhale theka la khama. Nthawi yomweyo, laser ya ulusi ikadula chitoliro, mutu wodula wa laser sukhudza chitoliro, koma umawonetsedwa ndi laser pamwamba pa chitoliro kuti usungunuke ndikudula, kotero umakhala wa njira yosakhudzana ndi kukhudzana, popewa vuto la kusintha kwa chitoliro pansi pa njira yachikhalidwe yopangira. Gawo lodulidwa ndi fiber laser ndi loyera komanso losalala, ndipo palibe burr pambuyo podula. Chifukwa chake, ubwino wowirikiza wa kuchita bwino ndi khalidwe ndi chitsimikizo chofunikira kuti fiber laser idulidwe ikhale mphamvu yatsopano pakukonza mapaipi achitsulo.

2. Makonzedwe Opangidwa Mwamakonda kuti athandize kukonza bwino ndi kukweza khalidwe: kwa makampani opanga mipando, zinthu zazing'ono, zoonda, makamaka zimakhala ndi mawonekedwe a chitsulo chosapanga dzimbiri, timagwiritsa ntchito makonzedwe olunjika kuti tiwongolere bwino ntchito yokonza ndi kukonza bwino chitoliro cha makampani opanga mipando. Laser yapadera ya fiber laser, fiber yapadera, mutu wodula wa laser wa fiber wosakhala wachizolowezi, zabwino zonse za makonzedwe zimayang'ana kwambiri kuthekera kodula chitoliro chapadera mumakampani opanga mipando, kugwira ntchito bwino kwa chitoliro chachitsulo chosapanga dzimbiri cha specification yomweyo kumadulidwa ndi makina athu odulira a fiber laser wamba Pafupifupi 30%, pomwe kumabweretsa zotsatira zabwino zodulira.

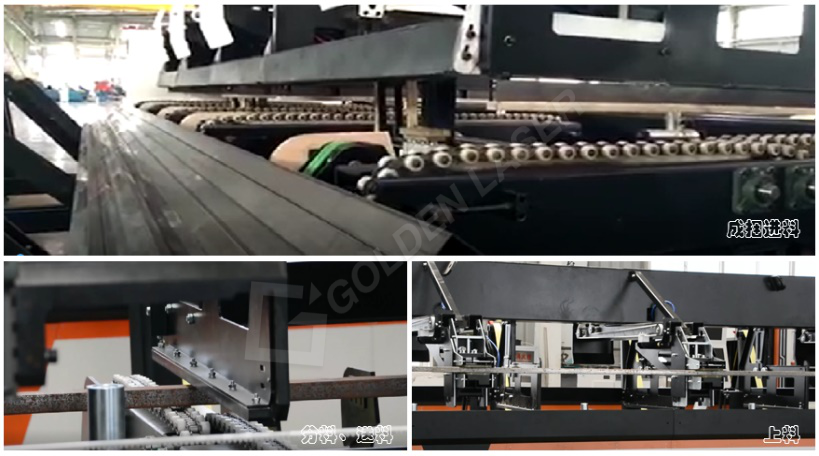

3. Kupanga mapaipi odzipangira okha: Pambuyo poti mapaipi olumikizidwa ayikidwa mu makina odyetsera okha, batani limodzi limayatsidwa, ndipo mapaipi amalowetsedwa okha, kugawidwa, kudyetsedwa, kulumikizidwa okha, kudyetsedwa okha, kudula ndi kutsitsa nthawi imodzi. Chifukwa cha ntchito yathu yokweza ndi kutsitsa yokha yomwe idapangidwa pa makina odulira mapaipi odzipangira okha a laser, chitolirochi chimatha kuzindikira kuthekera kokonza mapaipi ochulukirapo. Zipangizo zazing'ono zamapaipi mumakampani opanga mipando zimatenga malo ochepa. Zipangizo zamtundu womwewo zimatha kunyamula mapaipi ambiri mu katundu umodzi, kotero zimakhala ndi zabwino zambiri. Munthu m'modzi ali pantchito, ndipo njira yonse imamalizidwa yokha. Ichi ndi chitsanzo cha magwiridwe antchito.

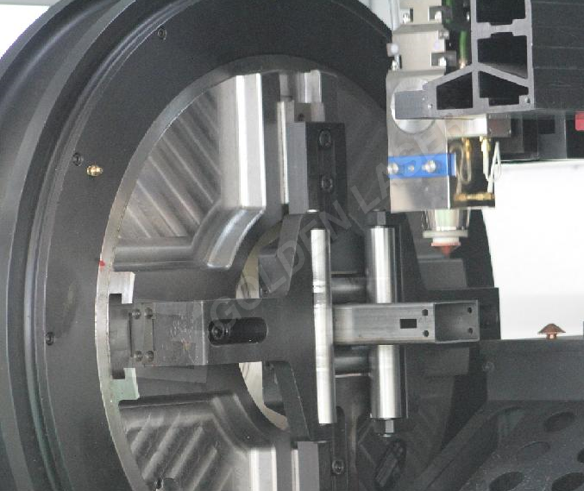

4. Kupumula kwa chubu: Pa chubu chaching'ono cha mafakitale a mipando, chubu chodulira cha laser chimakhala cholimba kwambiri. Ngati mphamvu yodulira ndi yayikulu kwambiri, chitolirocho chimasokonekera mosavuta, mphamvu yodulira ndi yaying'ono kwambiri, ndipo kutalika kwa chitoliro ndi kotalika. Panthawi yodulira, chitolirocho chimazungulira mofulumira kwambiri ndipo chimachotsedwa mosavuta. Chifukwa chake, mphamvu yodulira ya chuck ya zida zodulira chitoliro mumakampani opanga mipando iyenera kusinthidwa, ndipo njira yochotsera zolakwika iyenera kudziwika mosavuta. Chuck yodziyimira yokha yokonzedwa ndi makina odulira chitoliro cha laser yokha imatha kudziyimira yokha mu clamping ya chitoliro, kamodzi pamalo odulira, ndipo pakati pa chitoliro pali kamodzi. Nthawi yomweyo, mphamvu ya chuck clamping imachokera ku kuthamanga kwa mpweya wolowera. Mzere wolowera mpweya uli ndi valavu yowongolera kuthamanga kwa mpweya, ndipo mphamvu yodulira imatha kusinthidwa mosavuta pozungulira chogwirira pa valavu yowongolera kuthamanga kwa mpweya.

5. Mphamvu yothandiza komanso yodalirika: Kutalika kwa chitoliro kukakhala kwakutali, kusintha kwa chitoliro kumakhala koopsa kwambiri pambuyo poti chayimitsidwa. Chitolirocho chitayikidwa, ngakhale chuck itayikidwa isanayambe komanso itatha, gawo lapakati la chitoliro lidzagwa chifukwa cha mphamvu yokoka, ndipo kuzungulira kwachangu kwa chitolirocho kudzakhala njira yodumphadumpha, kotero kudulako kudzakhudza kulondola kwa kudula kwa chitolirocho. Ngati njira yachikhalidwe yosinthira chithandizo cha zinthu zapamwamba yagwiritsidwa ntchito, zofunikira zothandizira za chitoliro chozungulira ndi chitoliro chapakati zokha ndi zomwe zingathetsedwe, koma pakudula chitoliro cha mtundu wosakhazikika monga chitoliro cha rectangular ndi chitoliro cha elliptical, kusintha kwa chithandizo cha zinthu zapamwamba pamanja sikuli koyenera. Chifukwa chake, chithandizo cha pamwamba choyandama ndi chithandizo cha mchira cha kasinthidwe kathu ka zida ndi yankho laukadaulo. Chitolirocho chikazungulira, chiwonetsa mawonekedwe osiyanasiyana pamalopo. Chithandizo cha pamwamba choyandama ndi chithandizo cha zinthu zam'mbuyo zimatha kusintha kutalika kwa chithandizo nthawi yeniyeni malinga ndi kusintha kwa mawonekedwe a chitolirocho, kotero zitha kuwonetsetsa kuti pansi pa chitoliro nthawi zonse sichingalekanitsidwe ndi pamwamba pa shaft yothandizira, yomwe imagwira ntchito yothandizira ya chitoliro. Chothandizira pamwamba pa chitoliro choyandama ndi chothandizira chakumbuyo choyandama zimagwirira ntchito limodzi kuti chitolirocho chikhale chokhazikika bwino musanadule komanso mutadula, motero kuonetsetsa kuti kudulako kukuchitika molondola.

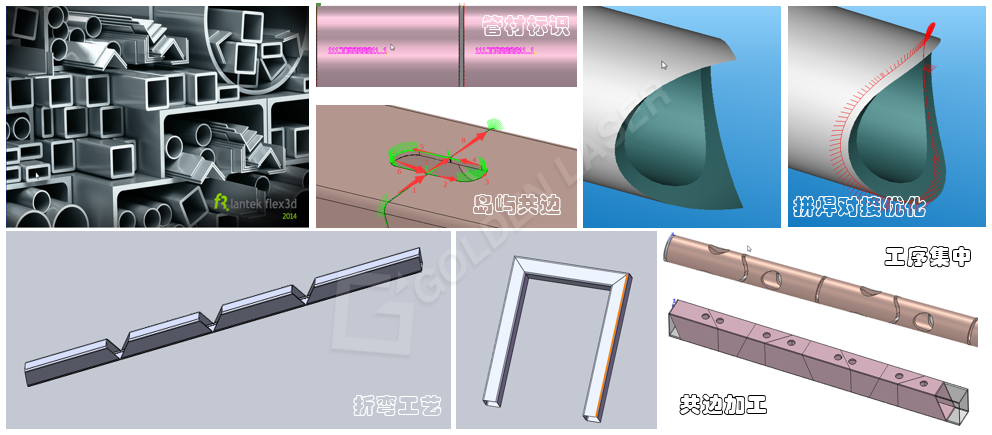

6. Kuchuluka kwa njira ndi kusiyanasiyana kwa njira: gwiritsani ntchito pulogalamu yojambulira ya 3D kuti mupange mapangidwe osiyanasiyana omwe amafunika kukonzedwa, monga kudula, kuphimba, kutsegula, kupukuta, kulemba, ndi zina zotero, kenako kuwasintha kukhala mapulogalamu opangira makina a NC mu sitepe imodzi kudzera mu pulogalamu yaukadaulo yopangira nesting. , lowetsani ku dongosolo laukadaulo la CNC la kasinthidwe ka chipangizocho, kenako tengani magawo ofanana a njira yodulira kuchokera ku database ya njira, ndipo makinawo akhoza kuyambika ndi batani limodzi. Njira yodulira yokha imamaliza kudula kwachikhalidwe, galimoto, kubowola, kubowola ndi njira zina. Kumaliza kwa njirayi pakati kumabweretsa kulondola kowongolera komanso kotsimikizika kokonza, komanso kugwira ntchito bwino kwambiri komanso mtengo wotsika. Kuwonjezera ndi kuchotsa mavuto a masamu kuyenera kukhala komveka bwino kwa wogwiritsa ntchito bizinesi aliyense.

7. Kugwiritsa ntchito makina odulira ulusi wa laser wa akatswiri pa mapaipi a mipando yachitsulo kwabweretsa kusintha kwatsopano paukadaulo wokonza mapaipi. Kuyambira pomwe tinayamba kufufuza ndi kupanga makina odulira ulusi wa laser wokha, takhala tikudziyika tokha mumakampani, zomwe zimapangitsa kuti makampaniwa akhale ozama, akatswiri, komanso osamala. Makampani opanga mipando yachitsulo akhala chitsanzo cha makina athu odulira mapaipi. Paulendo wofufuza ndi chitukuko, kufufuza ndi kupanga zinthu zatsopano kwa zaka zambiri, tasonkhanitsa zambiri zaukadaulo ndipo tapanga zatsopano zambiri zogwira mtima komanso zatsopano pamakampani opanga mipando. Njira. Kufunika koyambirira kolumikizidwa, tsopano kumatha kumangidwa ndikukonzedwa; kufunika koyambirira kolumikizidwa, kumatha kupindika mwachindunji; kugwiritsa ntchito chitoliro choyambirira ndikochepa kwambiri, tsopano titha kugwiritsa ntchito ntchito yodula m'mphepete kuti tipeze ndalama zabwino zosungira chitoliro ndi zinthu zambiri. Kupatula apo, njira zatsopano zokonzera izi zimagwiritsidwa ntchito mu chitoliro chokonzera mapaipi cha mafakitale a mipando, ndipo zabwino zake ndi ogwiritsa ntchito zida zathu.

Laser kudula Machine Pakuti Chitsulo Mipando