Iphuzu elibuhlungu njengamanje embonini yokukhiqiza ifenisha yensimbi

1. Inqubo iyinkimbinkimbi: ifenisha yendabuko ithatha inqubo yokukhiqiza yezimboni yokukhetha—ukusika umbhede ngesaha—ukucubungula umshini wokujika—indawo ethe njo—ukubhoboza ukuvimbela isikhundla kanye nokubhoboza—ukubhoboza—ukuhlanza—ukushisela kokudlulisa kudinga izinqubo ezingu-9.

2. Kunzima ukucubungula ithubhu elincane: imininingwane yezinto zokusetshenziswa zokukhiqiza ifenisha ayiqinisekile. Encane kunazo zonke10mm*10mm*6000mm, futhi ubukhulu bodonga lwepayipi ngokuvamile0.5-1.5mmInkinga enkulu ekucutshungulweni kwepayipi elincane ukuthi ipayipi ngokwalo linokuqina okuphansi futhi liguquguquka kalula ngamandla angaphandle, njengokugoba ipayipi, ukusonta, nokuvuvuka ngemva kokukhipha. Izinqubo zokucubungula zendabuko, njengokusika umshini wokusaha, isigaba sokucubungula umshini wokusaha kanye nokugoba, ukubhoboza ngesibhakela, ukubhoboza umshini wokubhoboza, njll., ziyizindlela zokucubungula ukuxhumana eziphoqa ukuma kwepayipi ukuthi kuguquguquke ngenxa yokukhipha amandla angaphandle, kanye nezinqubo eziningi kanye nabantu abaningi. Ukugeleza kokucubungula, amandla okuvikela epayipi cishe awakho, ngokuvamile kuze kube sezingeni lokugcina lomkhiqizo oqediwe, ubuso bepayipi buklwebhekile noma bukhubazeke, futhi kudinga ukulungiswa kwesibili ngesandla, okuthatha isikhathi futhi kukhathaza.

3. Ukunemba okungekuhle komshini wokugaya: Ngaphansi kwendlela yokucubungula yendabuko yepayipi yefenisha yensimbi, ukunemba okuphelele kwepayipi akunakuqinisekiswa. Kungakhathaliseki ukuthi umshini wokugaya njengomshini wokusika, umshini wokubhoboza noma umshini wokubhoboza, kuneziphambeko zomshini wokugaya, ikakhulukazi imishini yokucubungula enezinga eliphansi lokulawula okuzenzakalelayo. Lapho ukulandelana kwenqubo kuningi, kulapho iphutha lokugaya liqongelela khona. Zonke izindlela zokucubungula ezingenhla zidinga ukungenelela komuntu ekulawulweni kwenqubo, futhi iphutha lomuntu lizongezwa ephutheni lokugcina lokunemba komkhiqizo. Ngakho-ke, ukunemba kwendlela yendabuko yokucubungula izinqubo eziningi akulawuleki futhi akuqinisekisiwe. Esigabeni sokugcina somkhiqizo, ukulungiswa nokulungiswa ngesandla kuyisimo esijwayelekile.

4. Ukusebenza kahle kokucubungula okuphansi: Umshini wokusaha unezinzuzo ezithile zokusika kanye nokuxubha amapayipi amaningi ngokuvumelanayo, kodwa ukusebenza kahle kokusika kokuvulwa kwepayipi kuphansi kakhulu, futhi kuyadingeka ukushintsha i-engeli yokusika kanye nendawo ye-blade yesaha ukuze kubekwe futhi kunqunywe ngezindlela eziningi, okungelula futhi okungenzeki. Ukunemba kokulawula. Ukucindezela kokushaya kungasetshenziswa ekubhobozeni imigodi ejwayelekile efana nemigodi eyindilinga kanye nemigodi eyiskwele. Kodwa-ke, kunezinhlobo eziningi zezinhlobo zemigodi embonini yefenisha. Umshini wokubhoboza unekhono elikhulu lokucubungula imigodi enjalo, ngaphandle kokuthi ikhasimende libangela ukuchitha ulwazi oluningi kanye nezindleko ukuthuthukisa izinhlobo ezahlukene zesikhunta. Wonke umuntu uyazi ukuthi umshini wokubhoboza ungacubungula imigodi eyindilinga kuphela, futhi ukucubungula kunqunyelwe kakhulu. Imikhawulo yokucubungula kanye nokungasebenzi kahle kwenqubo ngayinye kuphumela ekungasebenzeni kahle komkhiqizo jikelele.

5. Izindleko eziphezulu zabasebenzi: Ngokusika, ukubhoboza kanye nokubhoboza ngendlela yendabuko yokucubungula, isici esikhulu kunazo zonke ukungenelela komuntu. Ukusebenza kwedivayisi ngayinye kudinga ukugadwa ngesandla, ngoba ukuzenzekela kwemishini enjalo kuphansi kakhulu. Ukuze kucutshungulwe izinto ezinjalo zokucubungula amapayipi ezingezona amashidi, ukulawulwa ngesandla kuyadingeka engxenyeni ngayinye yokondla, ukubeka, ukucubungula kanye nokubuyisela. Ngakho-ke, kungabonakala kaningi embonini yokucubungula ifenisha, imishini eminingi, abasebenzi abaningi. Namuhla, ngokuthuthuka kwezimo zemakethe, abanikazi bamabhizinisi bakhala ngokuthi abasebenzi baya ngokuya behamba, futhi baba nzima kakhulu ukuqasha. Izidingo zamaholo zabasebenzi nazo ziyakhuphuka. Izindleko zabasebenzi zingaba yingxenye enkulu yenzuzo yenkampani.

6. Ikhwalithi yomkhiqizo engeyinhle: Ukunemba kanye nekhwalithi yepayipi eliqediwe kuthinta ngqo umkhiqizo wokugcina. I-Burr, ukuguqulwa komshini okuphambene, ukungcola odongeni lwangaphakathi lwepayipi, njll. akuvunyelwe ekukhiqizeni ifenisha yekhwalithi ephezulu. Kodwa-ke, kungakhathaliseki ukuthi ukusika umshini, ukubhoboza, noma ukubhoboza, akungabazeki ukuthi lezi zinkinga zizodalulwa ngemva kokucubungula ipayipi. Umsebenzi wokususa ipayipi ngesandla, ukusika, kanye nokuhlanza emisebenzini elandelayo awunakugwenywa.

7. Kukhona ukuntuleka okukhulu kokuguquguquka: Namuhla, isidingo sabathengi siya ngokuya siba ngesakho, ngakho-ke ukwakheka kwefenisha yesikhathi esizayo ngokuqinisekile sekuya ngokuya kwenziwa ngokwezifiso. Umshini wokusaha wendabuko, umshini wokubhoboza, umshini wokubhoboza kanye neminye imishini sekuphelelwe yisikhathi, futhi ubuciko obulula abukwazi ukusekela umklamo omusha kanye nogqozi lokudala. Khanyisa ube ngokoqobo. Ukungasebenzi kahle, ikhwalithi ephansi, kanye nokushiyeka okubiza kakhulu kwemodi yokucubungula yendabuko kuzophazamisa kakhulu ijubane locwaningo kanye nokuthuthukiswa kwemikhiqizo emisha, futhi kunikeze imakethe isiqalo esihle.

Yimaphi amasu amasha angalethwa yi-laser pipe cutter ezenzakalelayo ngokuphelele efenisha

Imboni yokukhiqiza? Yiziphi izici zemishini?

1. Amandla amasha amakhulu ekucutshungulweni kwamapayipi ensimbi e-bismuth: ukusika i-laser yefayibha kuyisikhali esisha sokucubungula insimbi eminyakeni yamuva nje. Kamuva, kancane kancane kuthatha indawo yokugunda, ukubhoboza, ukubhoboza kanye nokusaha kwendabuko. Izinto zepayipi nazo ziyinsimbi, kanti ipayipi lemboni yefenisha lenziwe ngensimbi engagqwali, okuhambisana nezinzuzo zokusika i-laser yefayibha. Ukusebenza kahle kokuguqulwa kwe-photoelectric kwe-laser yefayibha, ikhwalithi enhle kakhulu ye-beam, amandla e-laser agxilile kakhulu, igebe lokusika elihle, lingasetshenziswa ekucutshungulweni kwamapayipi embonini yefenisha. I-rotary chuck yomshini wokusika i-laser yefayibha we-Vexo laser othomathikhi ngokugcwele inesivinini sokujikeleza esifinyelela ku-120 rpm, kanye nekhono le-laser yefayibha lokusika insimbi engagqwali ngesivinini esiphezulu kakhulu. Ukuhlanganiswa kwalokhu okubili kwenza ukusebenza kahle kokucubungula ipayipi kube yisigamu somzamo. Ngesikhathi esifanayo, lapho i-laser yefayibha isika ipayipi, ikhanda lokusika i-laser alithinti ipayipi, kodwa livezwa nge-laser ebusweni bepayipi ukuze lincibilike futhi lisike, ngakho-ke lingokwemodi yokucubungula engathintani, ligwema ngempumelelo inkinga yokuguqulwa kwamapayipi ngaphansi kwemodi yokucubungula yendabuko. Ingxenye enqunywe yi-fiber laser icocekile futhi ibushelelezi, futhi akukho burr ngemva kokusika. Ngakho-ke, izinzuzo ezimbili zokusebenza kahle kanye nekhwalithi ziyisiqinisekiso esibalulekile sokuthi ukusika i-fiber laser kube yiwona mandla amasha ayinhloko ekucutshungulweni kwamapayipi ensimbi.

2. Ukucushwa okwenziwe ngokwezifiso ukusiza ukusebenza kahle kokucubungula kanye nokuthuthukiswa kwekhwalithi: embonini yefenisha, izinto ezincane, ezincane, ikakhulukazi ziyizici zensimbi engagqwali, sisebenzisa ukucushwa okuqondiwe ukuthuthukisa ukusebenza kahle kokucubungula kanye nekhwalithi yokucubungula yepayipi lemboni yefenisha. I-module ekhethekile ye-fiber laser, i-fiber ekhethekile, ikhanda lokusika le-fiber laser elingajwayelekile, zonke izinzuzo zokucushwa zigxile ekhonweni lokusika lepayipi elikhethekile embonini yefenisha, ukusebenza kahle kwepayipi lensimbi engagqwali lencazelo efanayo kunqunywa umshini wethu ojwayelekile wokusika i-fiber laser Cishe u-30%, ngenkathi kulethwa imiphumela engcono yokusika.

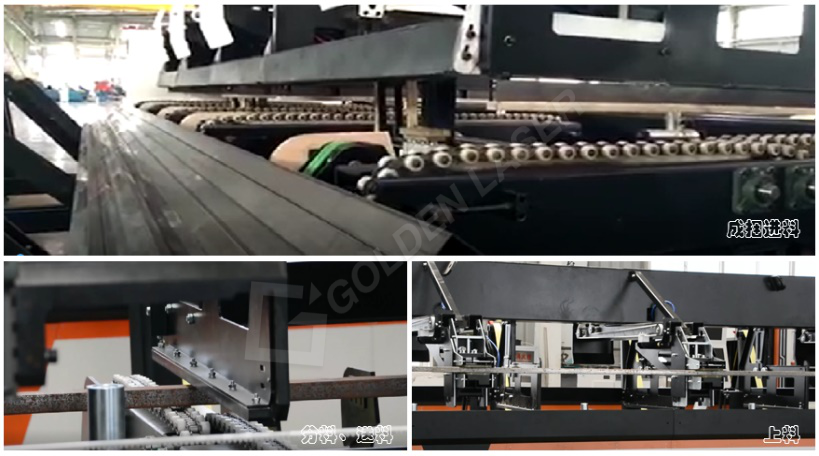

3. Ukukhiqizwa kwamapayipi ngokuzenzakalelayo: Ngemva kokuba amapayipi ahlanganisiwe efakwe emshinini wokondla okuzenzakalelayo, inkinobho eyodwa iyaqalwa, bese amapayipi ephakelwa ngokuzenzakalelayo, ahlukaniswe, aphakelwa, aboshwe ngokuzenzakalelayo, aphakelwa, asikwe futhi alayishwe ngesikhathi esisodwa. Ngenxa yomsebenzi wethu wokulayisha nokulayisha okuzenzakalelayo owakhiwe emshinini wokusika amapayipi we-laser ozenzakalelayo ngokuphelele, ipayipi lingabona ukuthi kungenzeka ukuthi kucutshungulwe amapayipi amaningi. Izinto ezincane zamapayipi embonini yefenisha zithatha isikhala esincane. Uhlobo olufanayo lwemishini lungapakisha amapayipi amaningi ngomthwalo owodwa, ngakho-ke lunezinzuzo eziningi. Umuntu oyedwa usemsebenzini, futhi yonke inqubo iqedwa ngokuzenzakalelayo. Lokhu kuyindlela yokusebenza kahle.

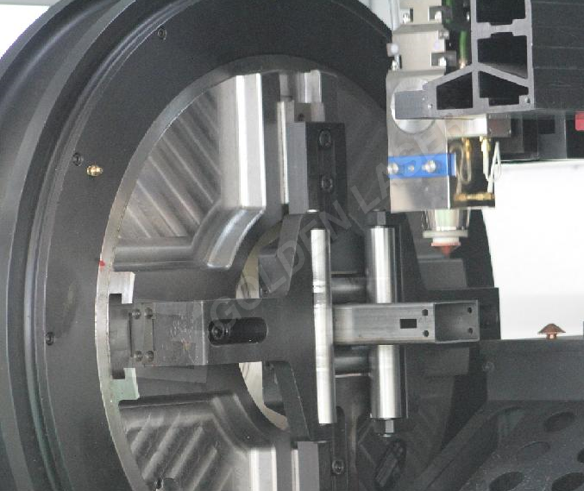

4. Ukuphumula kokubopha amashubhu: Kwishubhu elincane lemboni yefenisha, i-laser cutting chuck iqine kakhulu. Uma amandla okubopha makhulu kakhulu, ipayipi lishintsha kalula, amandla okubopha mancane kakhulu, futhi ubude bepayipi bude. Ngesikhathi senqubo yokusika, ipayipi lijikeleza ngesivinini esikhulu futhi lisuswa kalula. Ngakho-ke, amandla okubopha eshubhu lemishini yokusika amashubhu embonini yefenisha kumele alungiswe, futhi indlela yokulungisa amaphutha kumele ibonakale kalula. Ishubhu elizihlanganisayo elihlelwe ngumshini wokusika amashubhu e-laser ozenzakalelayo ngokuphelele lingakwazi ukuzihlanganisa lona ekubambeni kwamashubhu, kanye endaweni yokubopha, futhi isikhungo samashubhu sisendaweni kanye. Ngesikhathi esifanayo, amandla okubopha amashubhu atholakala ekucindezelweni komoya okufakwayo. Umugqa wokufaka igesi ufakwe i-valve yokulawula ingcindezi yegesi, futhi amandla okubopha angalungiswa kalula ngokujikeleza i-knob ku-valve yokulawula ingcindezi yomoya.

5. Amandla okusekela asebenzayo nathembekile: Uma ubude bepayipi bude, kulapho ukuguguleka kwepayipi kuba kubi kakhulu ngemva kokulengiswa. Ngemva kokuba ipayipi selilayishiwe, yize i-chuck iboshwe ngaphambi nangemva, ingxenye ephakathi yepayipi izogoba ngenxa yamandla adonsela phansi, futhi ukujikeleza kwepayipi ngesivinini esikhulu kuzoba isimo sokugxumagxuma, ngakho-ke ukusika kuzothinta ukunemba kokusika kwepayipi. Uma kusetshenziswa indlela evamile yokulungisa ngesandla yokusekela kwezinto eziphezulu, izidingo zokusekela zepayipi eliyindilinga kanye nepayipi lesikwele kuphela ezingaxazululwa, kodwa ekusikeni kwepayipi kohlobo lwesigaba esingajwayelekile njengepayipi elingunxande kanye nepayipi eliyindilinga, ukulungiswa ngesandla kokusekela kwezinto eziphezulu akusebenzi. Ngakho-ke, ukwesekwa okuphezulu okuntantayo kanye nokusekelwa komsila kokucushwa kwemishini yethu kuyisisombululo sobungcweti. Lapho ipayipi lijikeleza, lizobonisa ukuma okuhlukile esikhaleni. Ukusekelwa kwezinto eziphezulu okuntantayo kanye nokusekelwa kwezinto zomsila kungalungisa ngokuzenzakalelayo ukuphakama kokusekela ngesikhathi sangempela ngokuya ngokushintsha kwesimo sepayipi, ngakho-ke kungaqinisekisa ukuthi phansi kwepayipi akuhlukani njalo nephezulu kweshaft yokusekela, edlala ukusekela okunamandla komphumela wepayipi. Isisekelo sezinto ezintantayo kanye nesisekelo sezinto ezintantayo zisebenza ndawonye ukugcina ukuzinza kwepayipi ngaphambi nangemva kokusika, ngaleyo ndlela kuqinisekiswe ukunemba kokusika.

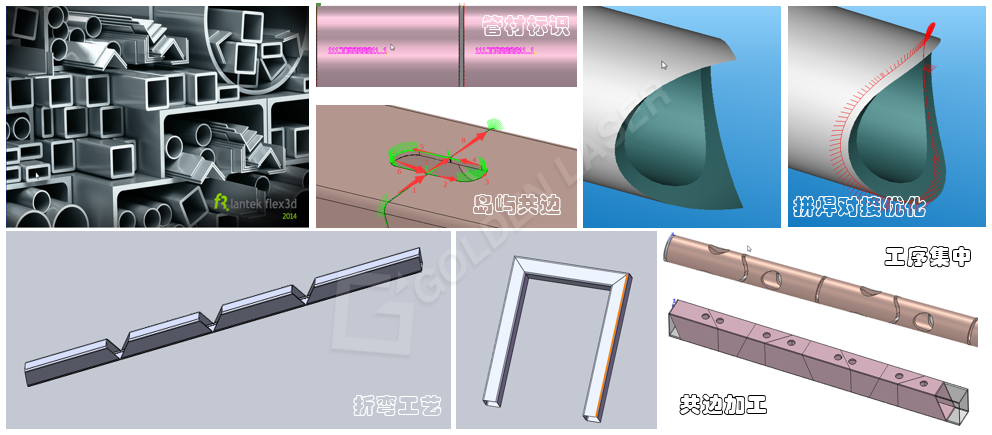

6. Ukugxila kwenqubo kanye nokwehlukahluka kwenqubo: sebenzisa isofthiwe yokudweba ye-3D ukuklama amaphethini ahlukahlukene adinga ukucutshungulwa, njengokunqunywa, ukujikijelwa, ukuvula, ukugoba, ukumaka, njll., bese uwaguqula abe izinhlelo zomshini we-NC ngesinyathelo esisodwa ngesofthiwe yobungcweti yokwenza izidleke. , ukufaka ohlelweni lobungcweti lwe-CNC lokucushwa kwedivayisi, bese uthola amapharamitha enqubo yokusika ahambisanayo kusuka kusizindalwazi senqubo, bese umshini ungaqalwa ngenkinobho eyodwa. Inqubo yokusika ezenzakalelayo iqeda ukusaha kwendabuko, imoto, ukubhoboza, ukubhoboza nezinye izinqubo. Ukuqedwa kwenqubo okuphakathi kuletha ukunemba kokucubungula okulawulwayo nokuqinisekiswayo, kanye nokusebenza kahle okuphezulu kanye nezindleko eziphansi. Lokhu kwengeza nokususa izinkinga zezibalo kumele kucace kuwo wonke umqhubi webhizinisi.

7. Ukusetshenziswa kwemishini yokusika i-fiber laser yobungcweti yamapayipi embonini yefenisha yensimbi kulethe izinguquko ezintsha kubuchwepheshe bokucubungula amapayipi. Selokhu saqala ucwaningo nokuthuthukiswa komshini wokusika i-fiber laser ozenzakalelayo ngokuphelele, sizibeke embonini, okwenza imboni ibe nzulu, yobungcweti, futhi icocekile. Imboni yefenisha yensimbi isibe yisibonelo somshini wethu wokusika amapayipi. Endleleni yocwaningo nokuthuthukiswa, ukuhlola kanye nokusungula izinto ezintsha eminyakeni edlule, siqoqe ulwazi oluningi lobuchwepheshe futhi sathuthukisa izinto ezintsha eziningi ezisebenzayo nezintsha embonini yokukhiqiza ifenisha. Inqubo. Isidingo sokuqala sokushiswa, manje singaboshwa futhi silungiswe; isidingo sokuqala sokuxhunywa, singagotshwa ngqo; ukusetshenziswa kwepayipi lokuqala kuphansi kakhulu, manje singasebenzisa umsebenzi wokusika onqenqemeni ovamile ukuze sithole ukonga okungcono kwamapayipi kanye nemikhiqizo eminingi. Ngaphandle, njalo njalo, lawa masu amasha okucubungula asetshenziswa ebhokisini lokucubungula amapayipi embonini yefenisha, futhi izinzuzo zingabasebenzisi bemishini yethu.

Umshini Wokusika we-Laser Wefenisha Yensimbi